Simple filter press filter board handle

A technology of filter press and plate handle, which is applied in the direction of filtration and separation, mechanical equipment, engine components, etc., can solve the problems of high labor intensity, reduced work efficiency, and slow moving speed of workers, so as to save materials, improve work efficiency, and connect convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

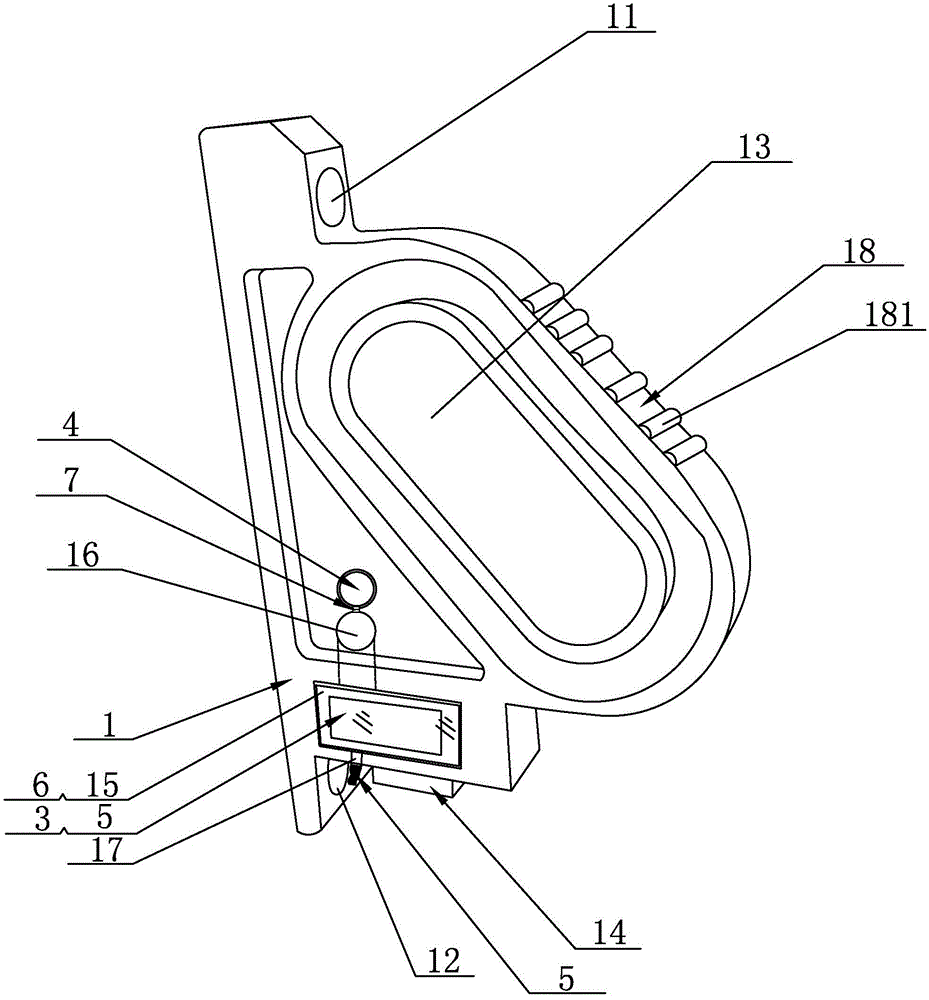

[0015] see figure 1 , a simple filter plate handle for a filter press disclosed in the present invention, comprising a handle body 1, the upper end of the handle body 1 is provided with a first connecting hole 11, and the lower end of the handle body 1 is provided with a second connecting hole 12, and the handle body 1 is provided with a second connecting hole 12. The right end of 1 is provided with a hand insertion hole 13, the said hand insertion hole 13 is a waist-shaped hole, the said hand insertion hole 13 is inclined downward from left to right, and its inclination angle is 30-60°, and the lower end of the handle body 1 is integrally provided with The slider 14, the handle body 1 is located directly above the slider 14 and is provided with an oil storage chamber 15, the upper end of the oil storage chamber 15 is provided with a lubricating oil filling hole 16, and one end of the lubricating oil filling hole 16 is hinged with a sealing cover 4 , the lower end of the oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com