Synchronization clamping apparatus for part components with various cross sections

A technology of synchronous clamping and parts, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of low efficiency and inconvenient use process, and achieve the effect of high clamping efficiency and novel structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

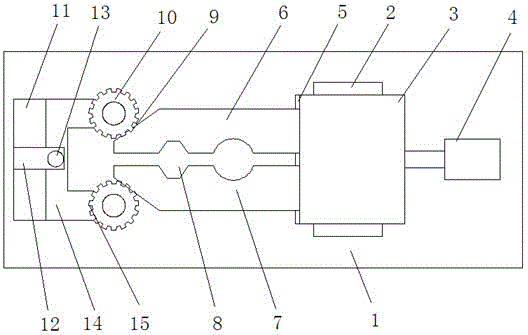

[0011] See attached picture:

[0012] The synchronous clamping device for components with different cross-sections includes a worktable 1, a fixed seat 2 is installed on the upper end of the worktable 1, and a sliding seat 3 is installed on the upper end of the fixed seat 2 to slide along the left and right directions. The end of the piston rod of the horizontal propulsion cylinder 4 is fixed, and the front end of the slide seat 3 is provided with a longitudinal slide rail 5, on which slide rails 5 are mounted with symmetrically distributed upper clamping blocks 6, lower clamping blocks 7, and upper clamping blocks 6. Between the opposite surface of the lower clamping block 7, there is a clamping groove 8 matching the shape of parts with different cross-sections. The front ends of the upper clamping block 6 and the lower clamping block 7 are wedge-shaped surfaces, and rolling teeth 9 are arranged on the wedge-shaped surfaces. A driven gear 10 meshed with rolling teeth 8 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com