Electro-hydraulic control clamping loose belt linkage device for maintenance and inspection of inclined belt conveyor

A belt conveyor, electro-hydraulic control technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of tape strength reduction, high operation requirements, safety hazards, etc., to reduce manufacturing costs and workload, entrain and pull belts Linkage is stable and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

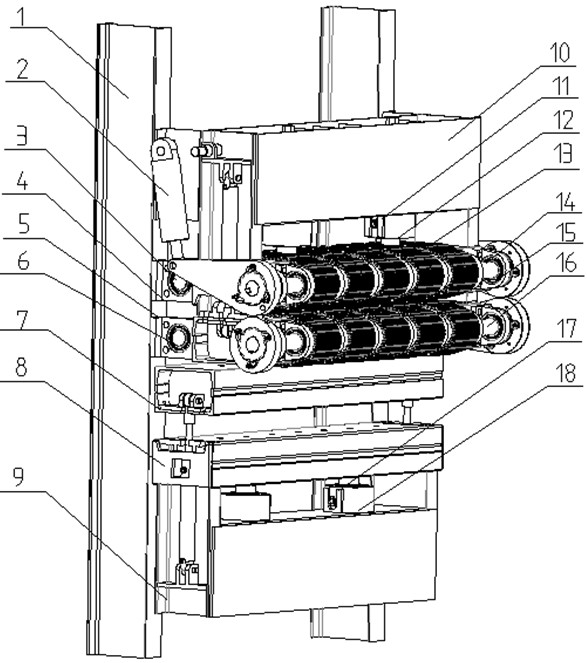

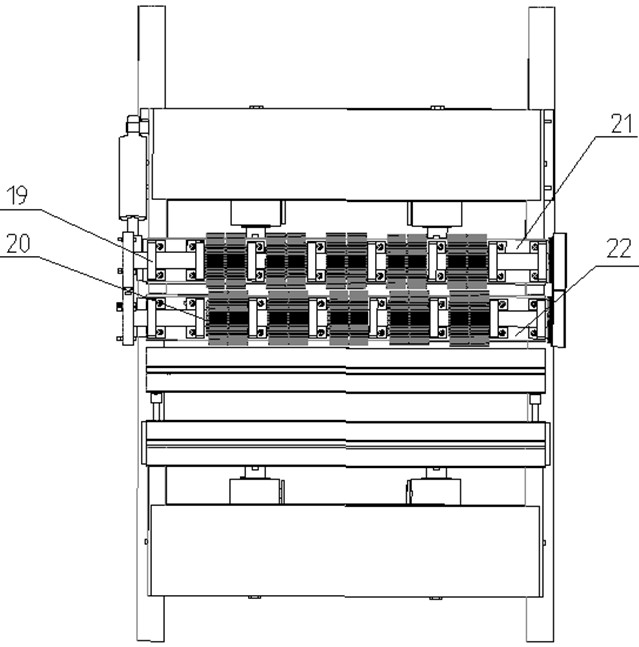

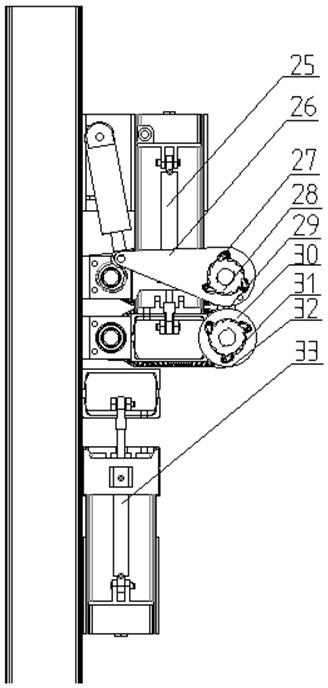

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Implement the above-mentioned electro-hydraulic control clamping loose belt linkage device for maintenance and inspection of inclined belt conveyors, as attached figure 1 As shown, the device is mainly composed of four parts: an electro-hydraulic control drive mechanism, an upper clamp mechanism, a lower clamp mechanism, and a main frame. Drive cylinder 2, upper ratchet housing one 26, upper ratchet housing two 23, upper driven shaft 3, lower driven shaft 6, upper ratchet 27, upper ratchet 28, lower ratchet housing one 32, lower ratchet housing two 24, lower Ratchet 30, lower pawl 31, upper brake oil cylinder 12, upper drive shaft 14, lower drive shaft 16, lower brake oil cylinder 18, upper lifting cylinder 25, and lower lifting cylinder 33 form an electro-hydraulic control drive mechanism; upper brake oil cylinder 12, lower Brake cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com