A single-control multi-point synchronous pressure entrainment device

A multi-point, hydraulic technology, used in transportation, packaging, conveyors, etc., can solve the problems of manpower and time consumption, large workload, and high operating requirements, reducing manufacturing costs and workload, and ensuring high adaptability and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

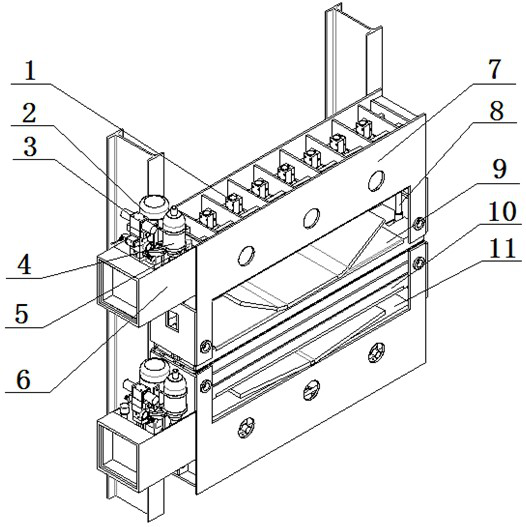

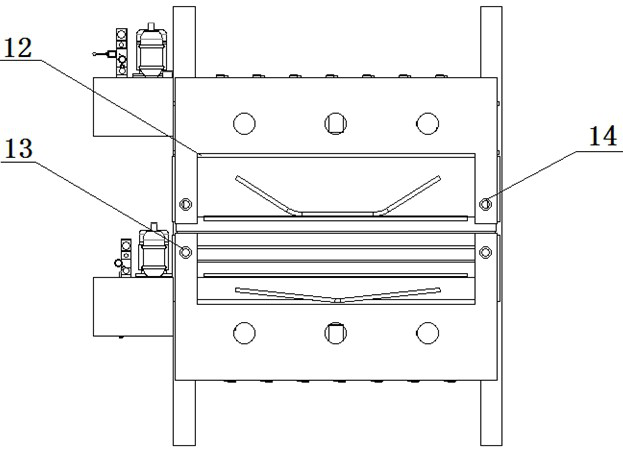

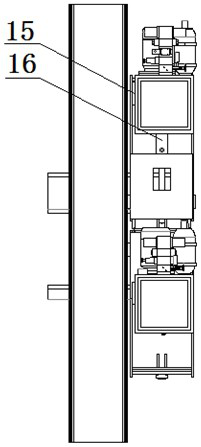

[0042] as attached figure 1 As shown, a single-control multi-point synchronous pressurization entrainment device is implemented. The device is mainly composed of four parts: hydraulic drive system, clamp body mechanism, gear opening adjustment mechanism, entrainment main body frame, hydraulic control check valve 1, entrainment Oil pump 2, entrainment control manifold 3, accumulator 4, air filter 5, entrainment oil tank 6, first piston cylinder 18, second piston cylinder 20, and plunger cylinder 19 form a hydraulic drive system; entrainment frame 7, The upper base 9 is entrained, the lower base 10 is entrained, the lower movable plate 11 is entrained, and the upper movable plate 12 is entrained to form a clip body mechanism; the first lifting cylinder 8, the second lifting cylinder 16, and the entrainment control integrated block 3 constitute an opening adjustment mechanism; The upper base 9, the entrainment lower base 10, the entrainment lower movable plate 11, and the entrain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com