Application of dicarboxylic alkali metal salt serving as zinc burning inhibitor

A technology of alkali metal carboxylic acid salt and zinc sintering inhibitor, which is applied in the application field of dibasic carboxylic acid alkali metal salt as zinc sintering inhibitor, can solve the problems of high price, restricted development space and the like, and achieves low cost and operation method. Simple and convenient, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

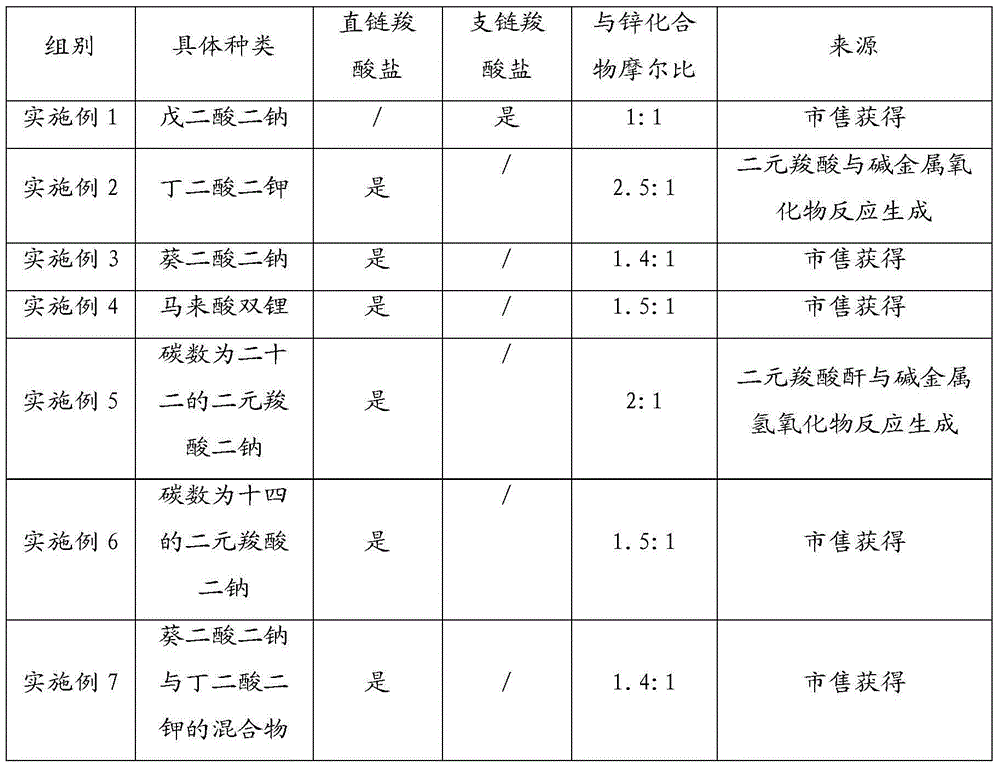

[0028] The selected dibasic carboxylic acid alkali metal salts are shown in Table 1 below:

[0029] The specific kind of the dibasic carboxylic acid alkali metal salt that table 1 selects for use

[0030]

Embodiment 3

[0032] Example 3: Grinding disodium sebacate until the particle size is below 0.05mm, dissolving and fully stirring, the stirring rate is controlled at 200rad / min;

Embodiment 4

[0033] Example 4: Dilithium maleate was pulverized until the particle size was between 0.01-0.03 mm, then dissolved and fully stirred, and the stirring rate was controlled at 300 rad / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com