Fore-trench rear-wheel type spinning back-drafting-zone pressure bar

A technology of pressure bar and drafting zone, which is applied in drafting equipment, spinning machines, textiles and papermaking, etc., can solve the problems of affecting the whole bundle, large frictional resistance, and many exposed fibers, so as to ensure the yarn quality and improve The effect of drafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

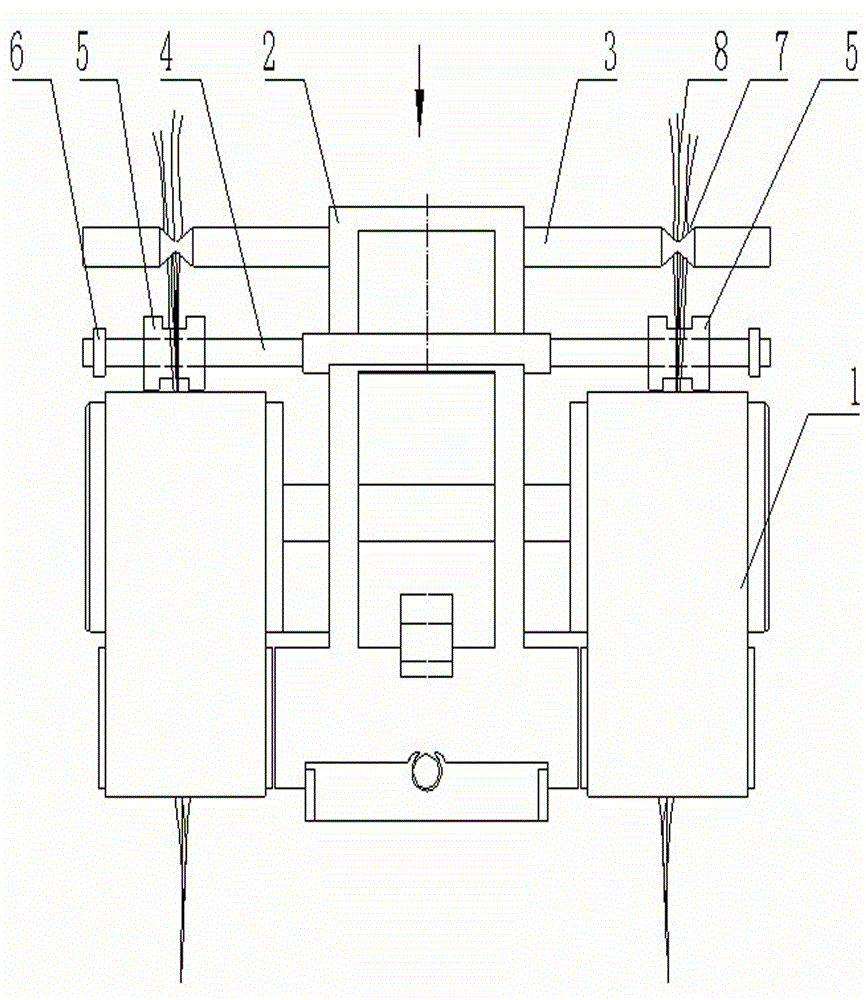

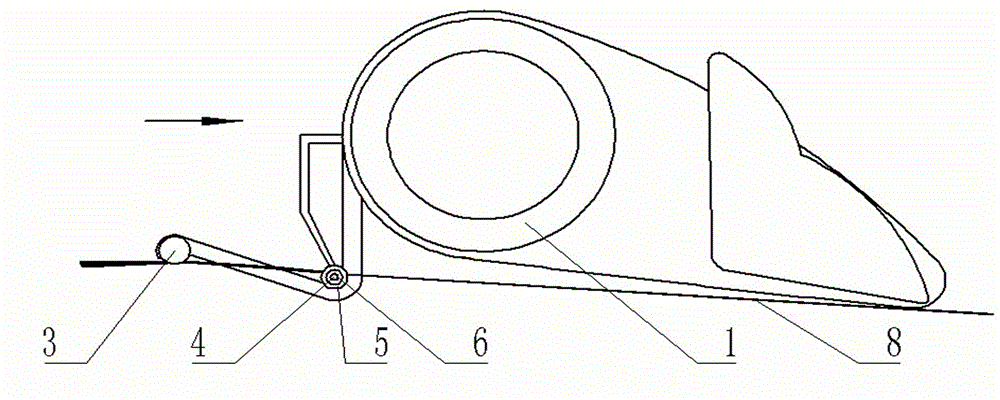

[0011] Such as figure 1 , figure 2 As shown, the present invention is a pressure bar in the rear drafting area of the front groove and rear wheel type spun yarn, which includes an upper pin combination 1, and the upper pins 2 of the upper pin combination 1 are alternately arranged with parallel lower pressure bars 3 and upper pressure bars 4 , the two ends of the upper pressure rod 4 are provided with snap rings 6, the upper pressure rod 4 inside the snap ring 6 is relatively provided with a groove wheel 5, and the lower pressure rod 3 is relatively provided with an annular groove 7.

[0012] The opening gap of the annular groove 7 is larger than the opening gap of the grooved wheel 5 .

[0013] The grooved wheel 5 and the upper pressure rod 4 are movable.

[0014] The technical advantage of the present invention is that without changing other structures of the exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com