Prefabricated steel structure self-resetting module based on support energy dissipation

A self-resetting, steel structure technology, applied to building components, building structures, earthquake resistance, etc., can solve problems such as failure to return to the original position, difficult maintenance and reinforcement of the structure, residual deformation of important components, etc., to shorten maintenance time and reduce maintenance cost, the effect of increasing the degree of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

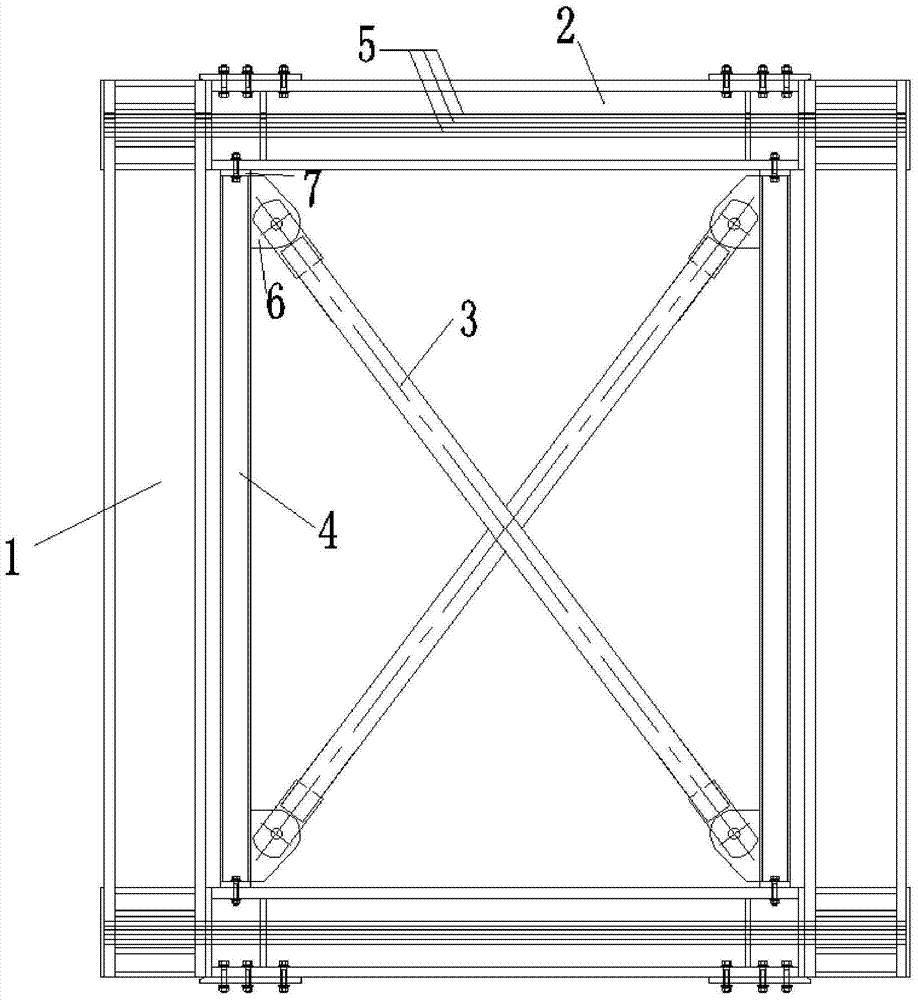

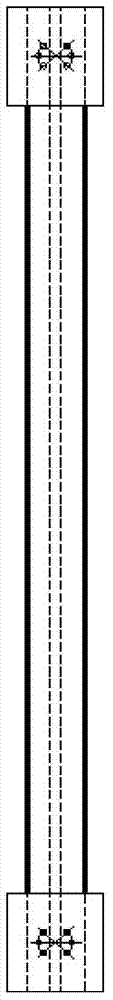

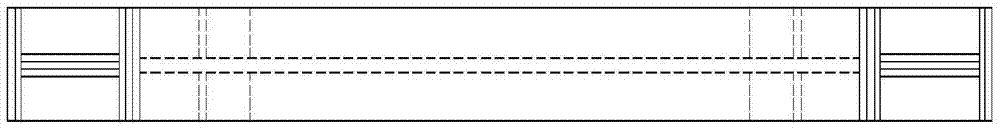

[0030] Embodiment 1: as figure 1 , 2 , 3, a prefabricated steel structure self-resetting module based on support energy dissipation, including two vertical edge members 1, two transverse edge members 2, two supports 3 and two hinged columns 4, along The two transverse edge members 2 are provided with several post-tensioned prestressed steel strands 5 and anchored on the outer flanges of the two vertical edge members 1 to form a prestressed frame; Two hinged columns 4 are arranged on the inner side, and end plates are arranged at both ends to connect to the flanges of the upper and lower transverse edge members 2 through high-strength bolts; two supports 3 are connected to the ear plates of the hinged columns through high-strength bolts, forming an X shape cross bracing.

[0031] The end of the vertical edge member 1 is provided with transverse stiffeners 13 to prevent local buckling of the plate and improve the mechanical properties of the member.

[0032] Transverse stiffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com