Floor board mounting assembly

A technology for installing components and floors, applied to floors, buildings, building structures, etc., can solve the problems of wasting natural resources, the floor cannot be recycled and reused, and the overall appearance of the floor is affected, so as to achieve the effect of not being easily damaged and protecting natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

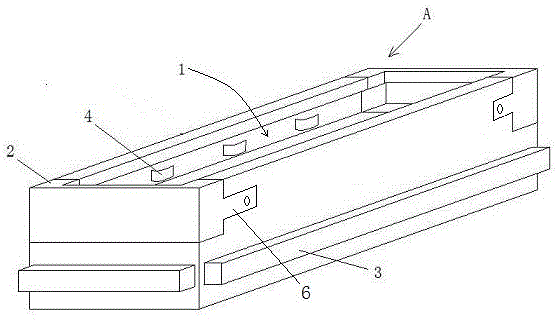

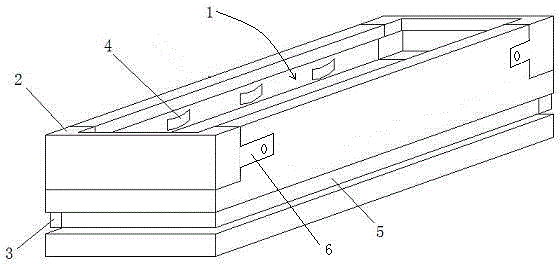

[0016] Such as figure 1 and figure 2 As shown in the floor installation assembly, the assembly is a metal or plastic product, and the front of the assembly is provided with a floor inlay groove 1, and the height of the inner cavity of the floor inlay groove 1 matches the height of the floor; the inner wall of the floor inlay groove 1 Protruding elastic parts 4 are provided on both sides; the elastic parts 4 are a plurality of elastic pieces arranged obliquely with respect to both sides of the inner wall of the floor inlay groove 1, and the plurality of elastic pieces face the same direction, and the floor inlay groove 1 The distance between the two sides of the inner cavity is slightly greater than the width of the floor, and the distance between the elastic parts 4 on both sides of the inner cavity of the floor inlay groove 1 is smaller than the width of the floor; both ends of the floor inlay groove 1 are also connected with end covers 2 , the distance between the opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com