Combined ultrahigh-lift drainage method and equipment

A combined, ultra-high technology, applied in the direction of mechanical equipment, non-variable pumps, components of pumping devices for elastic fluids, etc., can solve the problem that a single submersible pump cannot meet the drainage requirements of ultra-deep mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, an embodiment of the present invention is described further:

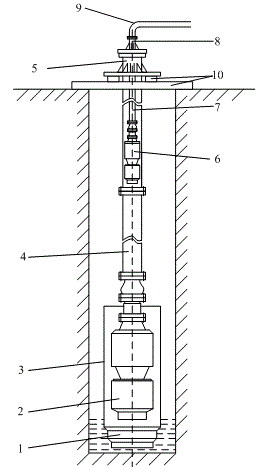

[0016] A combined super high head drainage method and equipment, such as figure 1 As shown, it includes a primary drainage system composed of a relay pump 1, a large submersible electric pump 2, a water suction cover 3, a large drainage pipeline 4 and a large seat tube 5, and a small submersible electric pump 6, a small drainage pipeline 7, and a small seat The secondary relay drainage system composed of pipe 8 and small elbow 9 is nested and combined; the large drainage pipe 4 of the primary drainage system is lowered into the mine water tank through flange connection, and the wellhead is fixedly installed in the mine by the large seat pipe 5 On the wellhead mounting frame 10; when working, first start the large submersible electric pump 2, and when the water level in the large drainage pipeline 4 reaches the minimum submersion depth of the small submersible e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com