Guide rail device capable of preventing wearing

A guide rail device and anti-wear technology, applied in the field of guide rail devices and machinery, can solve the problems of looseness and wear of guide rails and sliders, hidden dangers in the use of guide rail devices, etc., so as to achieve uniform force, prolong service life and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

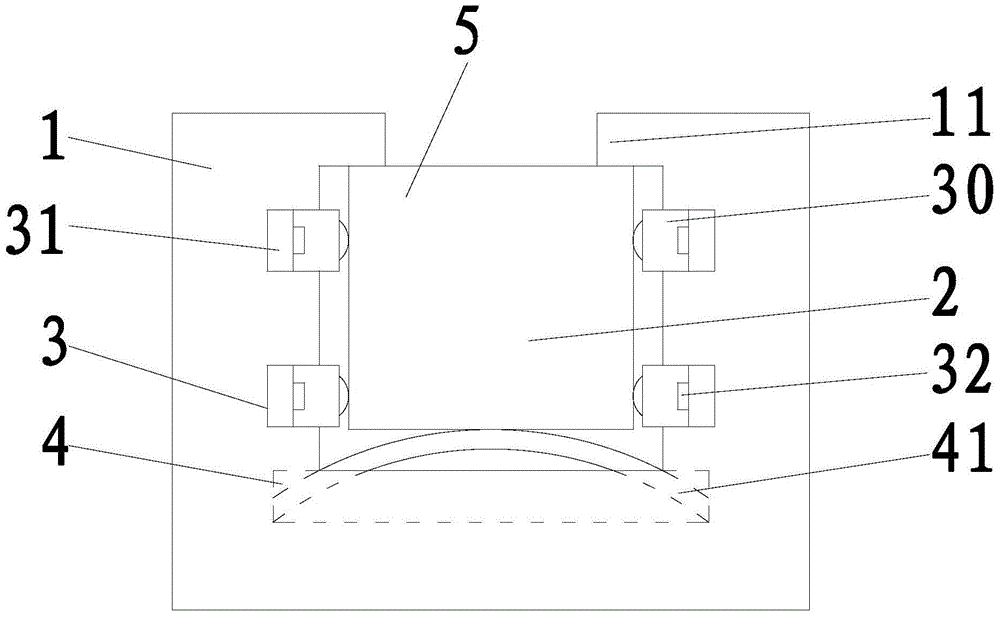

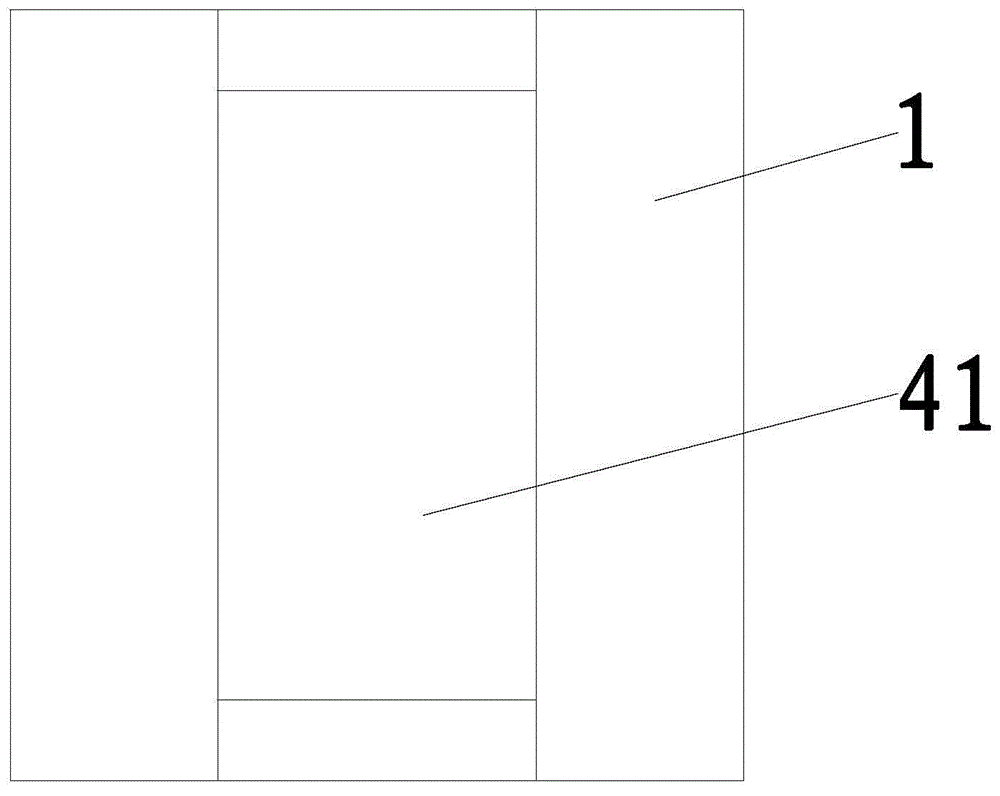

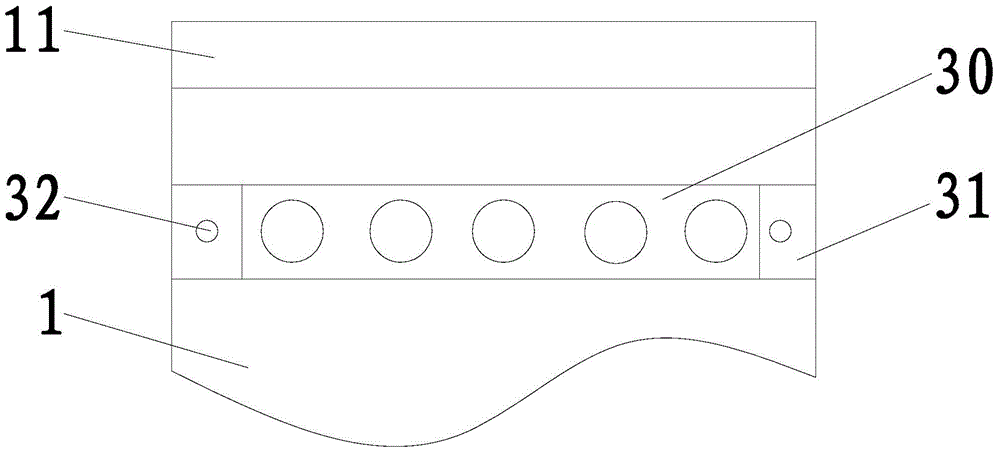

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , a wear-resistant guide rail device of the present invention, including a guide rail body 5, a slider body 1, a chute 2, and an auxiliary groove 4. There are several lubricating grooves 50 on the surface of the guide rail body 5, and the slider body 1 is installed on the guide rail body 5 Above, there is a chute 2 on the slider body 1, a baffle 11 on the top of the chute 2, the baffle 11 is in contact with the top of the guide rail body 5, an auxiliary groove 4 is located at the bottom of the chute 2, and there is an elastic pressing piece 41 in the auxiliary groove 4, The elastic pressing piece 41 is in contact with the bottom of the guide rail body 5. There are a number of installation grooves 3 on the side wall of the chute 2. Ball strips 30 are installed in the installation grooves 3. There are installation bosses 31 at both ends of the ball strip 30. The installation bosses 31 The bottom of the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com