Pseudo-static test device

A test device and quasi-static technology, applied in the field of quasi-static test devices, can solve the problems of inability to unload quickly, limited loading capacity, difficult to control loading and unloading, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

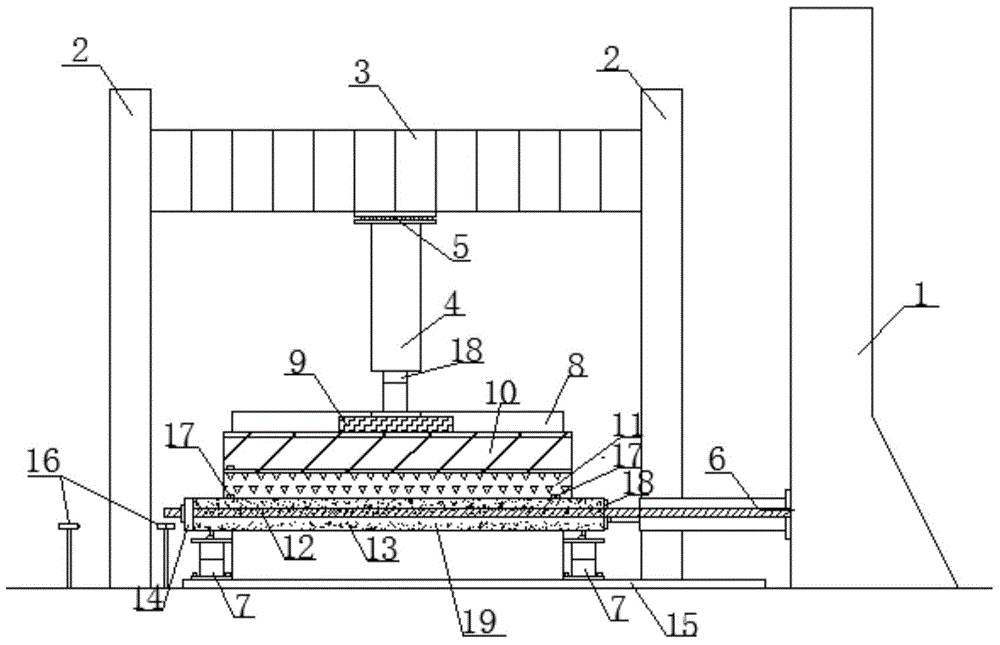

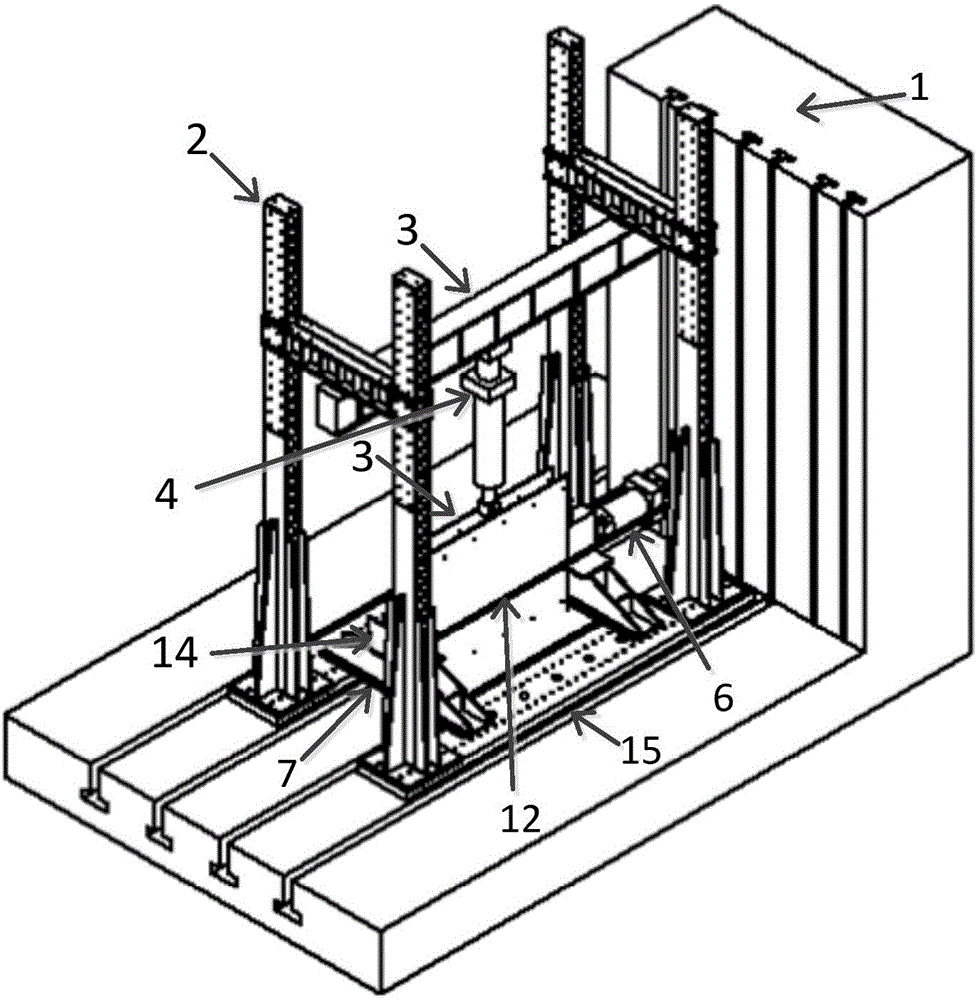

[0018] Such as figure 1 As shown, the quasi-static test device of the present invention is used to test the resistance-displacement full curve of the columnar member 13, including the reaction wall 1 and the door type reaction frame 2, the main beam 3 of the door type reaction frame 2 and the The reaction force wall 1 is vertical to the wall, and also includes a vertical actuator 4. The upper end of the vertical actuator 4 is connected to the main beam 3 through a ball joint 5, and the lower end of the vertical actuator 4 is pressed against the main beam 3. On the parallel distribution beam 9, it also includes the I-beam 10 placed under the distribution beam 9 and the water bag 11 placed under the I-beam 10, the column member 13 to be measured is placed under the water bag 11, and the The ground transition plate 15 and the two curved supports 7 fixed on the ground transition plate 15, the two curved supports 7 are located at the lower part of the column member 13 to be measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com