Tool for detecting high-temperature acoustic emission signal of thermal barrier coating

A technology of acoustic emission signal and thermal barrier coating, which is applied in the direction of material analysis using acoustic emission technology, can solve problems such as inability to work under high temperature conditions, avoid contact with high temperature environments, ensure no distortion, and reduce signal attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

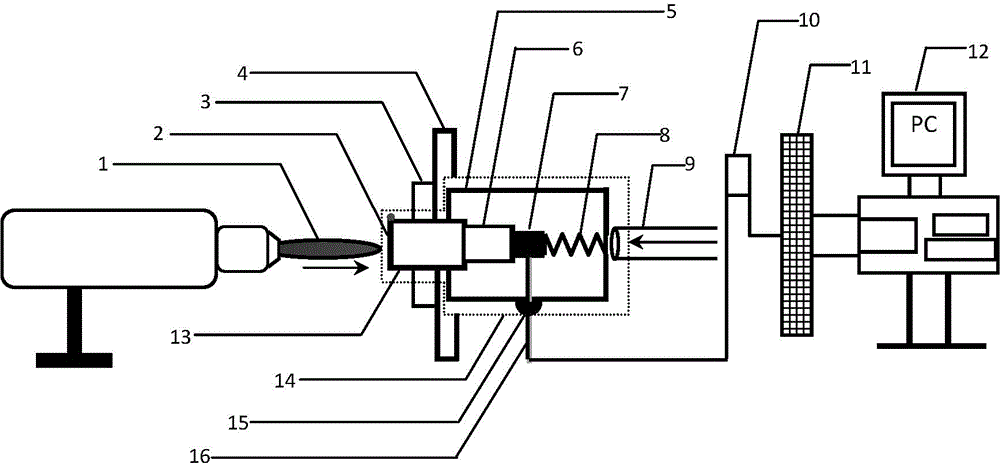

Method used

Image

Examples

Embodiment 1

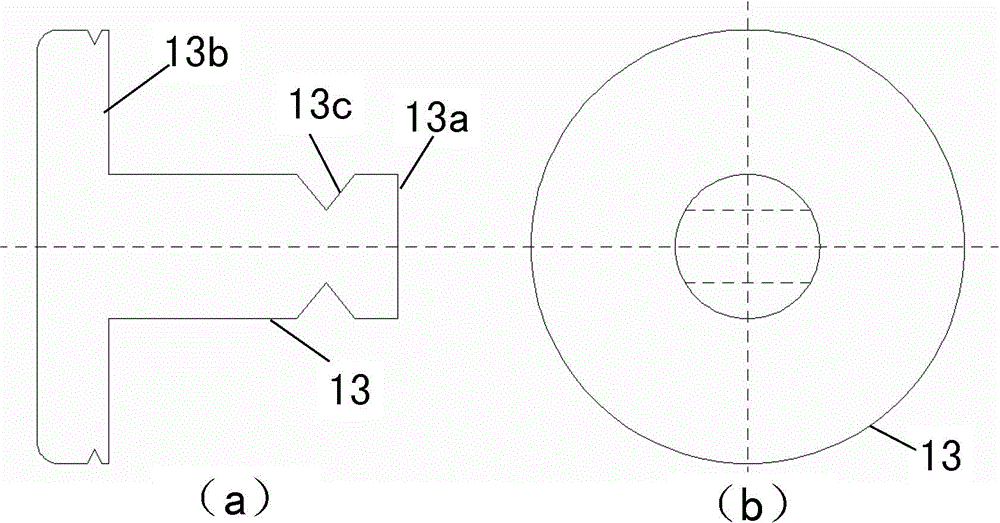

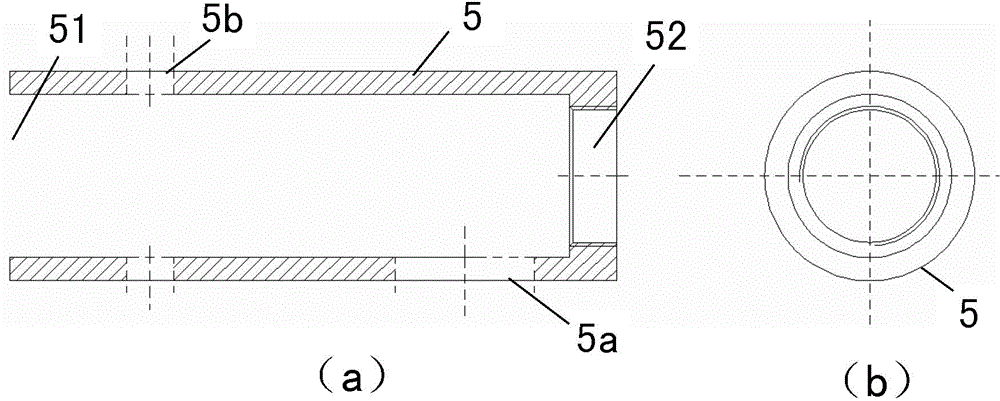

[0067] Prepare various accessories and parts required for the tooling according to the above plan, and make a backup copy if necessary. It mainly includes the processed sleeve (it needs to be confirmed against the drawing and the actual object before assembly), the initial length l 0 shorter and stiffer K Slightly larger spring, PTFE hose for compressed air, three M4 screws of appropriate length (after fixing the substrate, the end face of the screw should be close to the outer end face of the sleeve), high temperature solid lubricating sound transmission glue, high temperature Tape, pencil, lead, etc.

[0068] The assembly sequence is different, and must be assembled according to the correct operation sequence, including:

[0069] Connect the PTFE hose through the compressed air to the internal thread of the hollow sleeve M12;

[0070] Then put the short spring into the bottom end of the hollow sleeve, close to the bottom end of the M12 internal thread;

[0071] Then ali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com