Fault Diagnosis Method of Industrial Process Based on Direction Kernel Partial Least Squares

A nuclear partial least squares, industrial process technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve the obstacles to accurate modeling and accurate monitoring of the production process, can not achieve the effect, PLS residual space variation Large amount of problems, etc., to achieve the effect of rapid statistical overrun phenomenon, elimination of statistical overrun phenomenon, and solve fault diagnosis problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

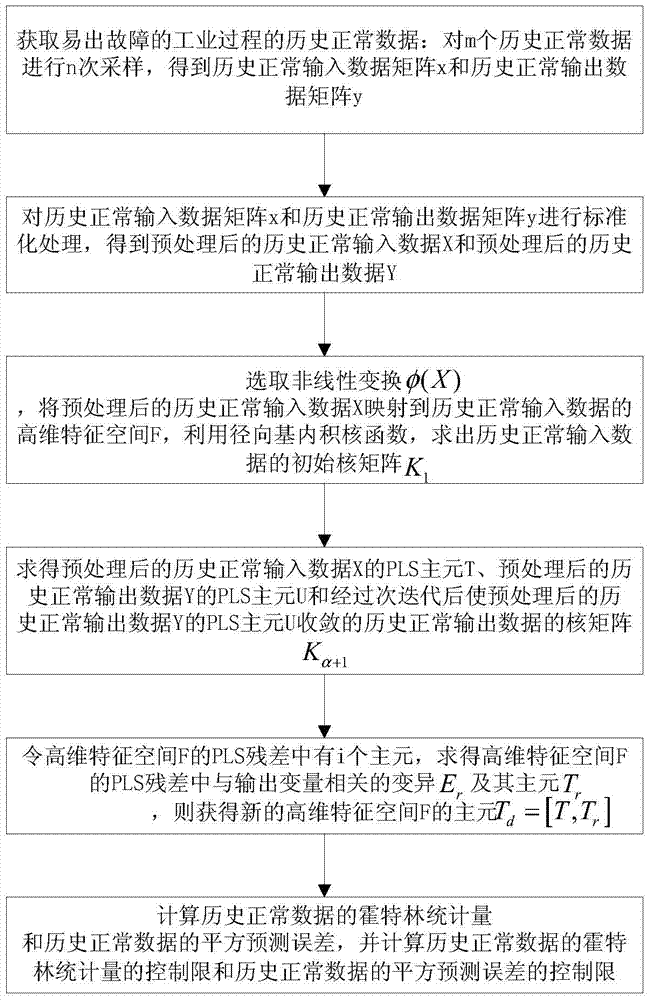

[0052] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0053] In view of the faults and bad working conditions that are prone to occur in the smelting process of the fused magnesium furnace, the temperature of the fused magnesium furnace is selected to be monitored. The temperature value in the furnace is an important parameter, and its value is determined by the current value in the electrode and the position of the electrode. Therefore, the input voltage value of one of the three electrodes, the three-phase current value, and the relative position of the electrode are three key variables. The input variable of the smelting process of the fused magnesium furnace takes the furnace temperature values corresponding to the three electrodes in the smelting process of the fused magnesium furnace as the output variable of the process model.

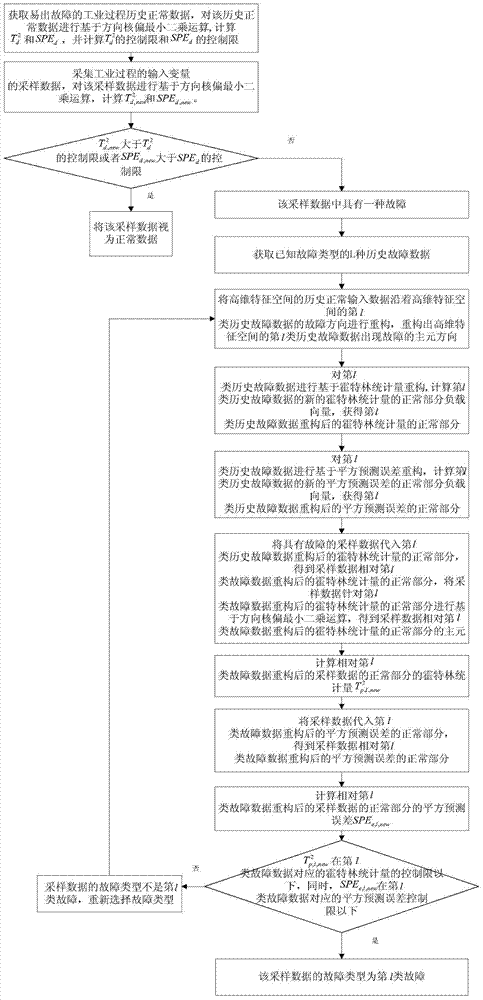

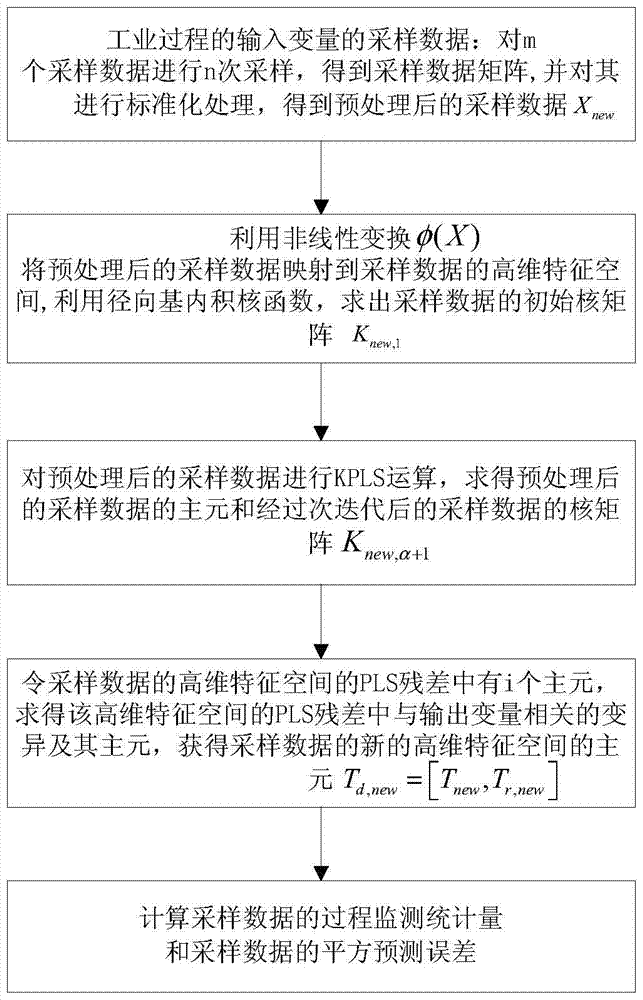

[0054] An industrial process fault diagnosis method bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com