Reduced-voltage starting control system

A starting control and autotransformer technology, which is applied to the starter, motor generator/starter, etc. of a single polyphase induction motor, can solve the problems of large mechanical impact, poor smoothness, and few starting stages, and achieves The effect of reducing impact, good starting smoothness and reducing mechanical impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

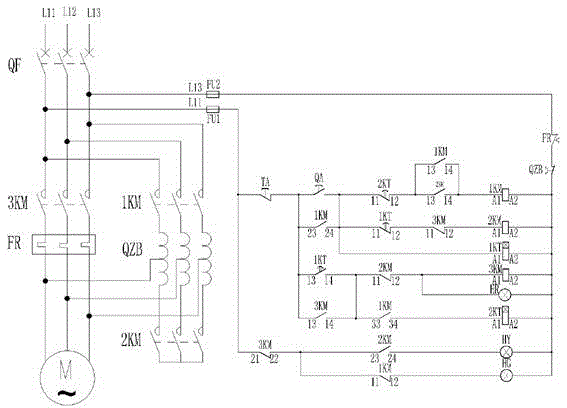

[0010] A step-down start control system, refer to figure 1 , Is the three-phase alternating current L11, L12, L13 through the circuit breaker QF respectively connected to the inlet end of the contactor 3KM main contact, the inlet end of the contactor 1KM main contact, the outlet end of the contactor 3KM main contact through the thermal relay FR is connected to the three-phase motor M and the three intermediate taps of the autotransformer QZB. The outlet end of the main contact of the contactor 1KM is connected to the power supply end of the autotransformer QZB, so that the contactor 3KM, thermal relay FR and contactor 1KM, autocoupling The transformer QZB is connected in parallel, the other end of the autotransformer QZB is connected to the inlet end of the 2KM main contact of the contactor, and the outlet end of the 2KM main contact of the contactor is shorted together;

[0011] The L11 of the three-phase alternating current is connected in series with the fuse FU1 and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com