Tool for sticking edge pad for loudspeaker

A technology for attaching speakers and tools, applied in the field of speaker pad edge installation devices, can solve problems such as inefficiency, sticking to hands, and inability to guarantee product quality, and achieves the effect of simple structure, time-saving and labor-saving production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further illustrate the present invention below in conjunction with accompanying drawing.

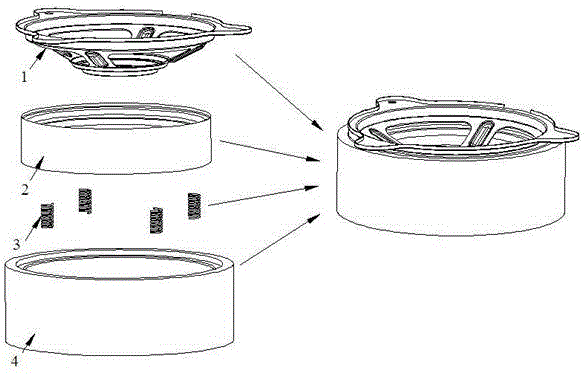

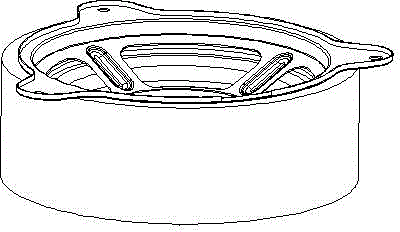

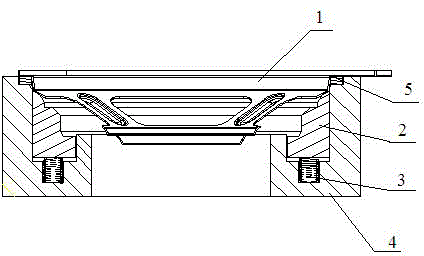

[0013] Such as figure 1 , 2 As shown in and 3, a tool for affixing the edge of a loudspeaker includes a seat cover 4, a return spring 3 and a movable block 2, the seat cover 4 is provided with a movable block installation groove, and the movable block installation groove has a built-in return spring 3, and the movable block The block 2 is inserted into the seat cover 4 according to the transition fit method and pressed against the reset 3, and the top of the seat cover 4 is provided with a pad groove. The inner shape of the movable block 2 matches the shape of the pot frame 1, and the movable block 2 is used to support the pot frame 1.

[0014] Wrap the straight edge 5 around the edge groove to form a circle, then put the pot frame 1 in, press the pot frame 1 and move down together with the movable block 2 until the edge 5 sticks, and finally take out the stuck pad The basin fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com