Natural edible plant micro powder product capable of improving nutrient releasing efficiency and eating safety and preparation method of natural edible plant micro powder product

A technology for releasing efficiency and nutrients, which is applied in the field of natural edible plant micropowder products and its preparation, can solve the problems of limiting the release of nutrients, absorption and utilization of nutrients, functional indigestion, etc., and achieve the effect of improving nutritional value and food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Put broccoli block (about 15g) in a sodium bicarbonate solution with a mass concentration of 0.1% for 60s (100°C) and immediately place it in ice water to cool for 5 minutes;

[0024] (2) Remove the cooled broccoli and drain;

[0025] (3) The drained broccoli is air-dried at 60° C. until the equilibrium moisture is lower than 10%;

[0026] (4) The dried broccoli is ultrafinely pulverized, and analyzed by a laser particle size analyzer, the average particle size (D50) is 31.2 μm, and 90% of the micropowder particle size is between 23 μm and 75 μm;

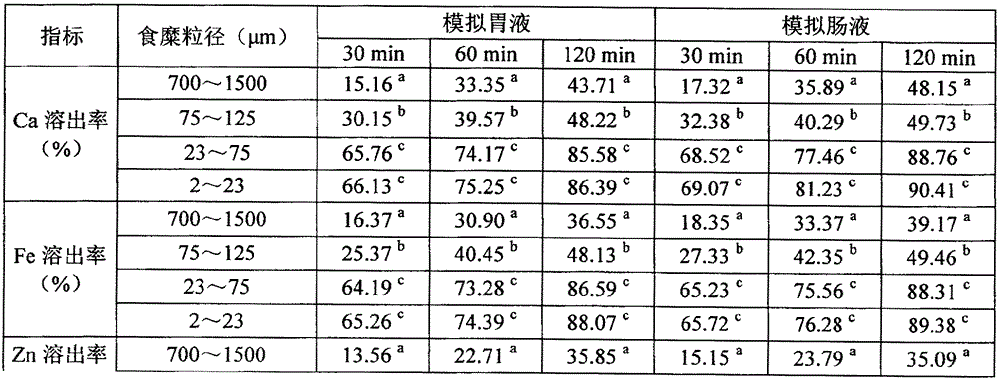

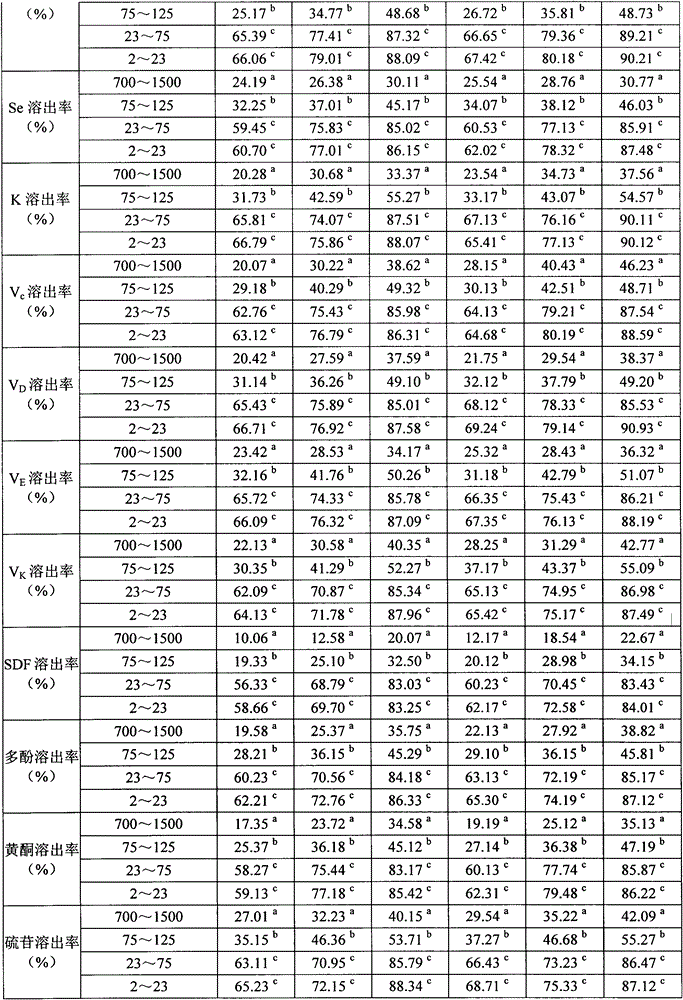

[0027] functional evaluation

[0028] Accurately measure 80mL of artificial gastric juice or artificial intestinal juice into the dissolution vessel, heat to keep the temperature of the solvent at (37±0.5)°C, adjust the rotation speed of the stirring paddle to keep it stable at 100r / min;

[0029] Accurately weigh a certain mass (150 mg) of the above-mentioned broccoli powder, and control samples of the same mass (the tr...

Embodiment 2

[0040] (1) Put the sliced cabbage (about 2cm×2cm) in 0.1MPa steam to protect the color for 120s, and then immediately put it in ice water to cool for 5 minutes;

[0041] (2) Remove the cooled cabbage and drain;

[0042] (3) Microwave drying the drained cabbage until the equilibrium moisture is lower than 10%;

[0043] (4) The dried cabbage is ultrafinely pulverized, and analyzed by a laser particle size analyzer, the average particle size is 29.5 μm, and 90% of the micropowder particle size is between 23 μm and 75 μm;

[0044] functional evaluation

[0045] Accurately measure 80mL of artificial gastric juice or artificial intestinal juice into the dissolution vessel, heat to keep the temperature of the solvent at (37±0.5)°C, adjust the rotation speed of the stirring paddle to keep it stable at 100r / min;

[0046] Accurately weigh a certain mass (150 mg) of the above-mentioned cabbage powder, and a control sample of the same mass (the treatment process is the same, but the p...

Embodiment 3

[0058] (1) Put the sliced banana (about 0.5cm in thickness) in a mass concentration of 0.5% CaCl 2 Soak in +0.5% Vc solution for 20min;

[0059] (2) Remove and drain the color-protecting bananas;

[0060] (3) Draining the dried bananas at 50° C. by infrared drying until the equilibrium moisture is lower than 10%;

[0061] (4) The dried bananas are ultrafinely pulverized, and analyzed by a laser particle size analyzer, the average particle diameter is 34.1 μm, and 90% of the micropowder particle diameters are between 23 μm and 75 μm;

[0062] functional evaluation

[0063] Accurately measure 80mL of artificial gastric juice or artificial intestinal juice into the dissolution vessel, heat to keep the temperature of the solvent at (37±0.5)°C, adjust the rotation speed of the stirring paddle to keep it stable at 100r / min;

[0064] Accurately weigh a certain mass (150 mg) of the above-mentioned banana powder, and a control sample of the same mass (the treatment process is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com