Improved structure based on columnar wood clamping device

A clamping device and wood technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as loosening of cylindrical wood, reduce the contact area, avoid loosening, and improve clamping stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

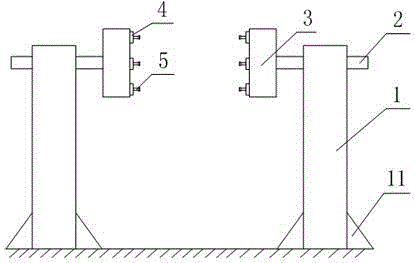

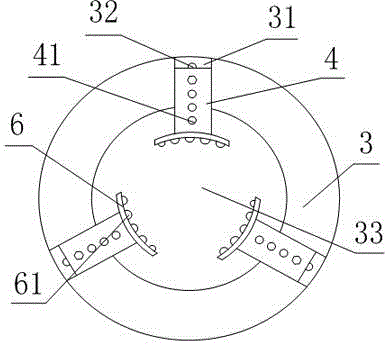

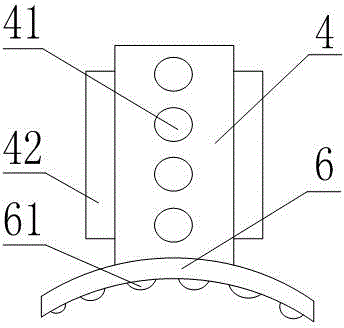

[0023] Such as Figure 1 to Figure 3 As shown, the improved structure based on the columnar wood clamping device includes two symmetrically arranged fixed columns 1, the bottom end of the fixed column 1 is provided with a reinforcing rib 11, the upper end of the fixed column 1 is provided with a fixed rod 2, and a fixed rod 2 As a rotating shaft driven by a motor, the end of the fixed rod 2 is provided with a fixed disk 3, and two fixed disks 3 are arranged oppositely on the inner side of the fixed column 1. The fixed disk 3 is provided with a fixed cavity 33 in the axial direction. The end surface of 3 is recessed in the axial direction to form three grooves 31, the bottom of the groove 31 is provided with a fixing hole 32 that cooperates with the bolt 5, and the side wall of the groove 31 is symmetrically provided with two clamping grooves. Both ends are provided with clamping plates 42 that are matched with the clamping grooves. The slider 4 is arranged in the groove 31 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com