CIJ inkjet printer printing speed control method

A printing speed and control method technology, applied to printing devices, printing, etc., can solve the problems of fixed printing speed, low ink drop utilization rate, and reduced printing effect, and achieve the goal of maintaining printing speed, improving printing clarity, and maintaining stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The CIJ printing speed control method disclosed by the present invention, its steps are:

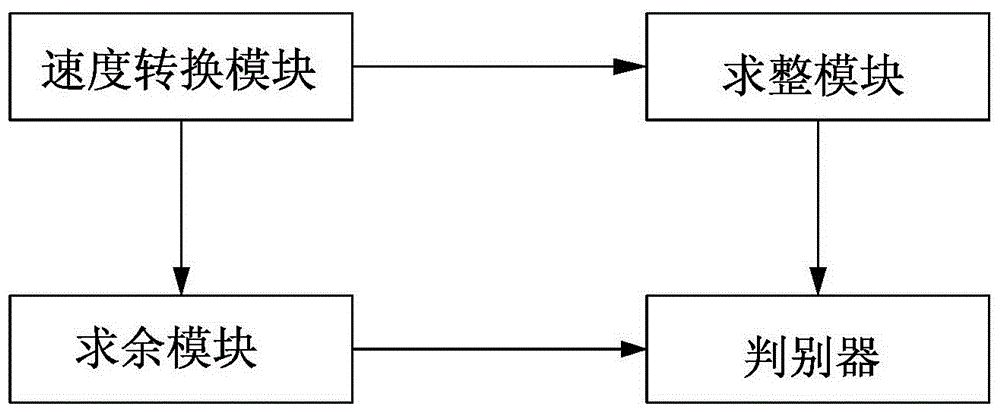

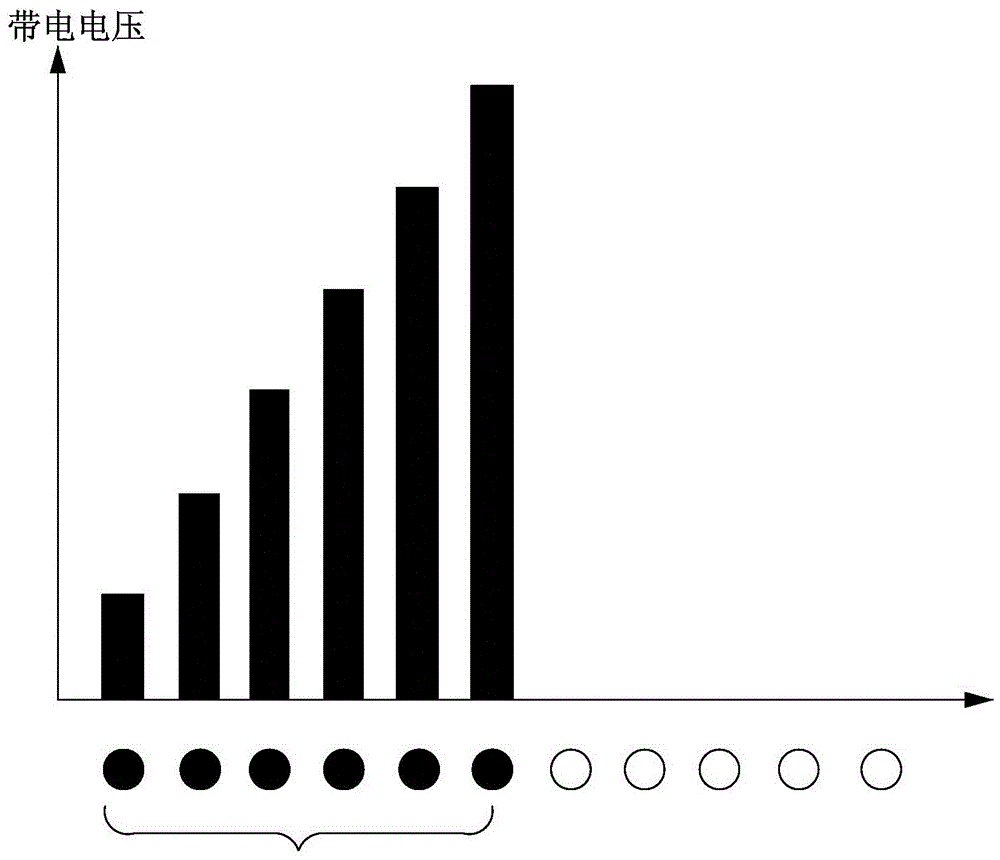

[0037] Step 1: Input the printing speed value in the host computer, and convert the printing speed value into the total value of ink droplets ejected to print a column of dot matrix through the speed conversion module;

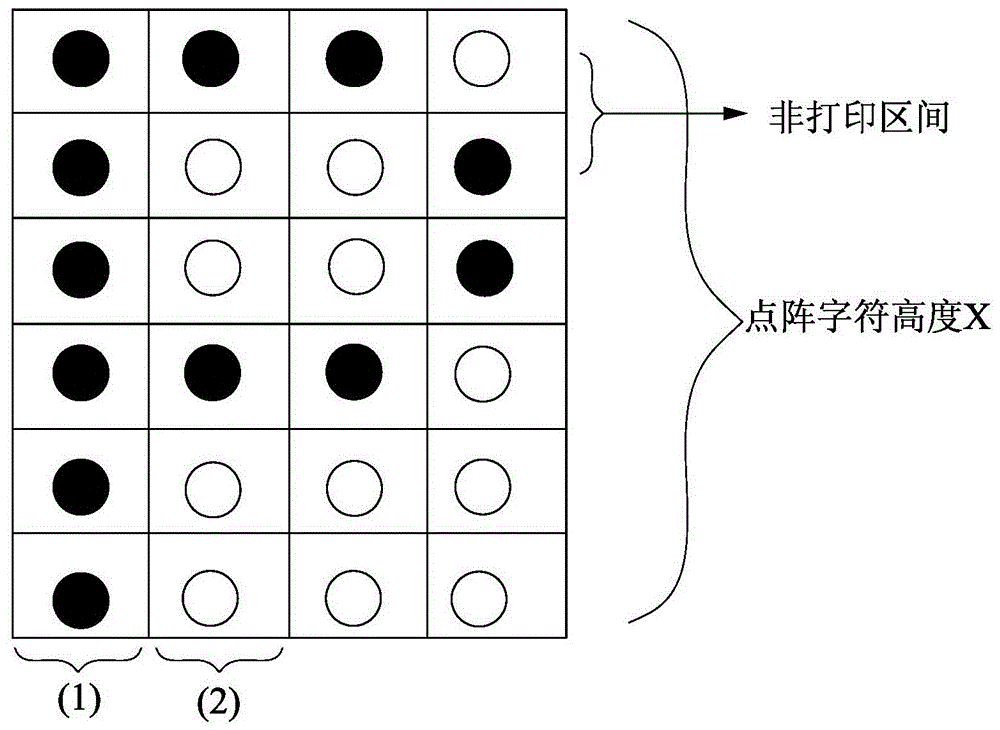

[0038] Step 2: The integer calculation module obtains the value of the first non-printing ink drop that needs to be inserted between two printing ink drops in the same column of dot matrix according to the total value of the ink drop, and the remainder module calculates the value of the first non-printing ink drop between the two columns of dot matrix according to the total value of the ink drop. The value of the second non-printing ink drop that needs to be inserted;

[0039] The calculation formulas of the first non-printing ink drop value and the first non-printing ink drop value are:

[0040] n=(D1-D2) / (X-1);

[0041] The first non-printing ink drop value N1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com