Gravure magenta ink for pure water type tipping paper and preparation method thereof

A technology of tipping paper and pure water type, applied in the field of gravure magenta ink for pure water type tipping paper and its preparation, can solve the problems of low production cost, reduce pollution, have good leveling, and save ink The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

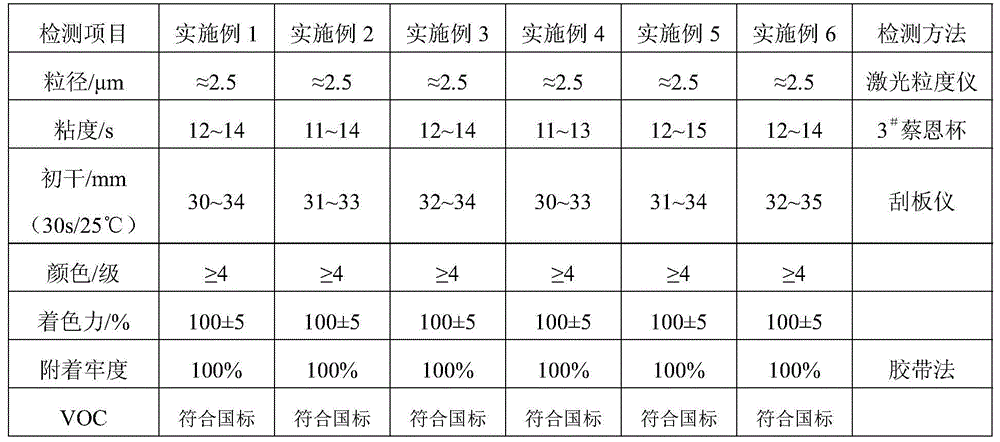

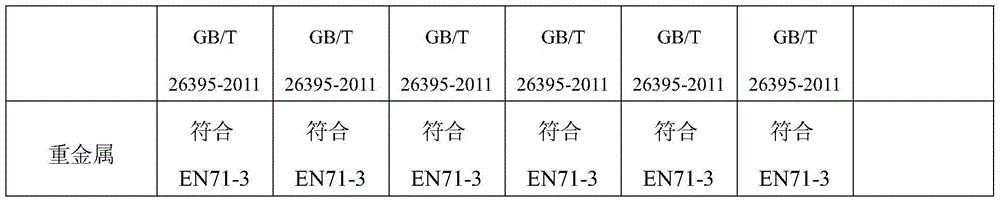

Examples

Embodiment 1

[0023] Take 20 parts of Everlasting Red with a balance, 40 parts of s-2916 resin (Oriental Yakeli Company), 36 parts of deionized water, 0.5 part of polyether siloxane copolymer (content 100wt.%), 1.5 parts containing Aqueous copolymer solution of pigment affinity group (concentration: 40wt.%), 2 parts of polysiloxane-polyether copolymer (content: 100wt.%). Pour the above components into the mixing device, stir with a mechanical mixer for 30 minutes to mix them evenly, then pour them into the grinding chamber of a sand mill, grind and disperse them with a sand mill for 100 minutes, and test their particle size, the particle size is less than or equal to 3 microns , stop grinding, if the particle size is greater than 3 microns, continue grinding until the particle size is less than or equal to 3 microns; then check the various indicators and properties of the ink, filter and pack after passing the test, and obtain the ink.

Embodiment 2

[0025] Take 25 parts of permanent red, 37.5 parts of s-2916 resin, 33 parts of deionized water, 1.5 parts of polyether siloxane copolymer, 2 parts of aqueous copolymer solutions containing pigment affinity groups (concentration is 40wt .%), 1 part polysiloxane-polyether copolymer. Pour the above components into the mixing device, stir with a mechanical mixer for 45 minutes to mix them evenly, then pour them into the grinding chamber of the sand mill, grind and disperse them with the sand mill for 90 minutes, and test their particle size, the particle size is less than or equal to 3 microns , stop grinding, if the particle size is greater than 3 microns, continue grinding until the particle size is less than or equal to 3 microns; then check the various indicators and properties of the ink, filter and pack after passing the test, and obtain the ink.

Embodiment 3

[0027] Take 22.5 parts of permanent red, 35 parts of s-2916 resin, 39 parts of deionized water, 1 part of polyether siloxane copolymer, 1 part of aqueous solution of copolymer containing pigment affinity group (concentration is 40wt .%), 1.5 parts of polysiloxane-polyether copolymer. Pour the above components into the mixing device, stir with a mechanical mixer for 30 minutes to mix them evenly, then pour them into the grinding chamber of a sand mill, grind and disperse them with a sand mill for 100 minutes, and test their particle size, the particle size is less than or equal to 3 microns , stop grinding, if the particle size is greater than 3 microns, continue grinding until the particle size is less than or equal to 3 microns; then check the various indicators and properties of the ink, filter and pack after passing the test, and obtain the ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com