wing anchor

A bolt and wing-type technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems such as the expansion of the end of the bolt, and achieve the effects of good support effect, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

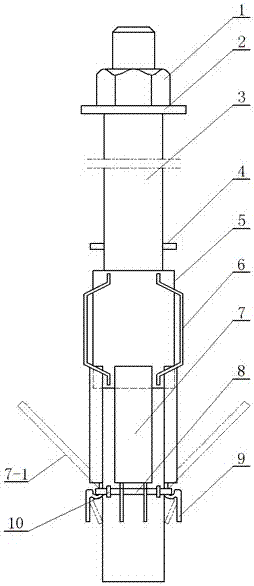

[0011] exist figure 1 Among them, the wing-type anchor rod includes: anchor nut 1, washer plate 2, anchor rod body 3, stop pin 4, push-wing steel pipe 5, positioning rib 6, wing 7, opened wing 7-1, Steel bar ring 8, wing curved ring 9, support station column 10; the wing anchor has a cylindrical anchor body 3, and the bottom of the anchor body 3 is provided with expandable plate-shaped wings 7, Steel bar ring 8 and wing curved ring 9 are provided with support stand column 10 between wing wing bend ring 9 and anchor rod body 3, and support station column 10 is welded together with anchor rod body 3, and wing bend ring 9 ends Welded at the root of the wing 7, and fastened in the hole of the steel ring 8 between the two supporting station columns 10, a push-wing steel pipe 5 is slid on the top of the steel ring 8, and on the surface of the push-wing steel pipe 5 120 degrees evenly distributed and welded with steel positioning ribs 6; on the anchor rod body 3 above the push-wing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com