Blower

A technology of blowing and sucking fans and fans, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc. It can solve the problems of affecting the use of users, poor flow expansion effect, and low wind pressure, and achieve the effect of improving the efficiency of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

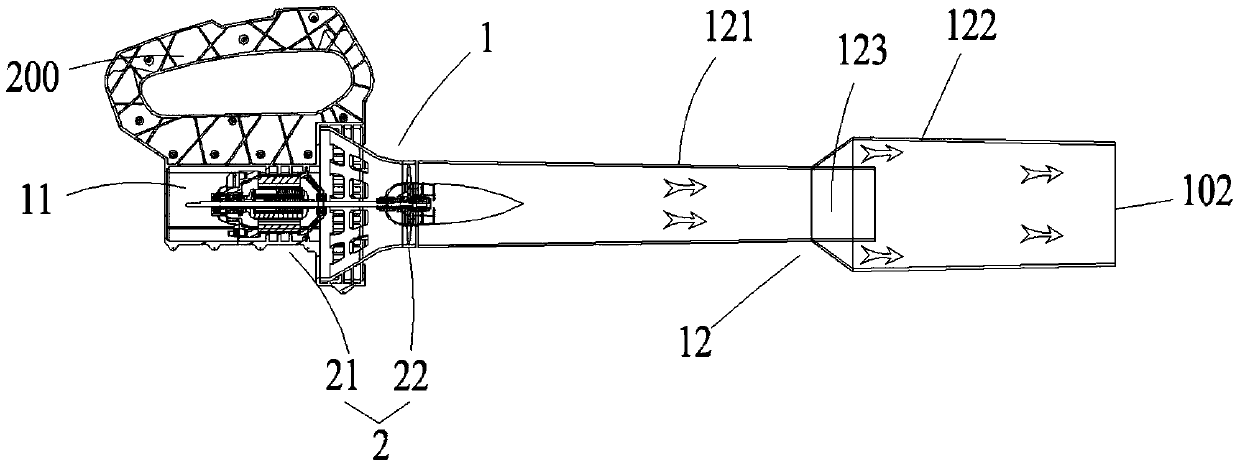

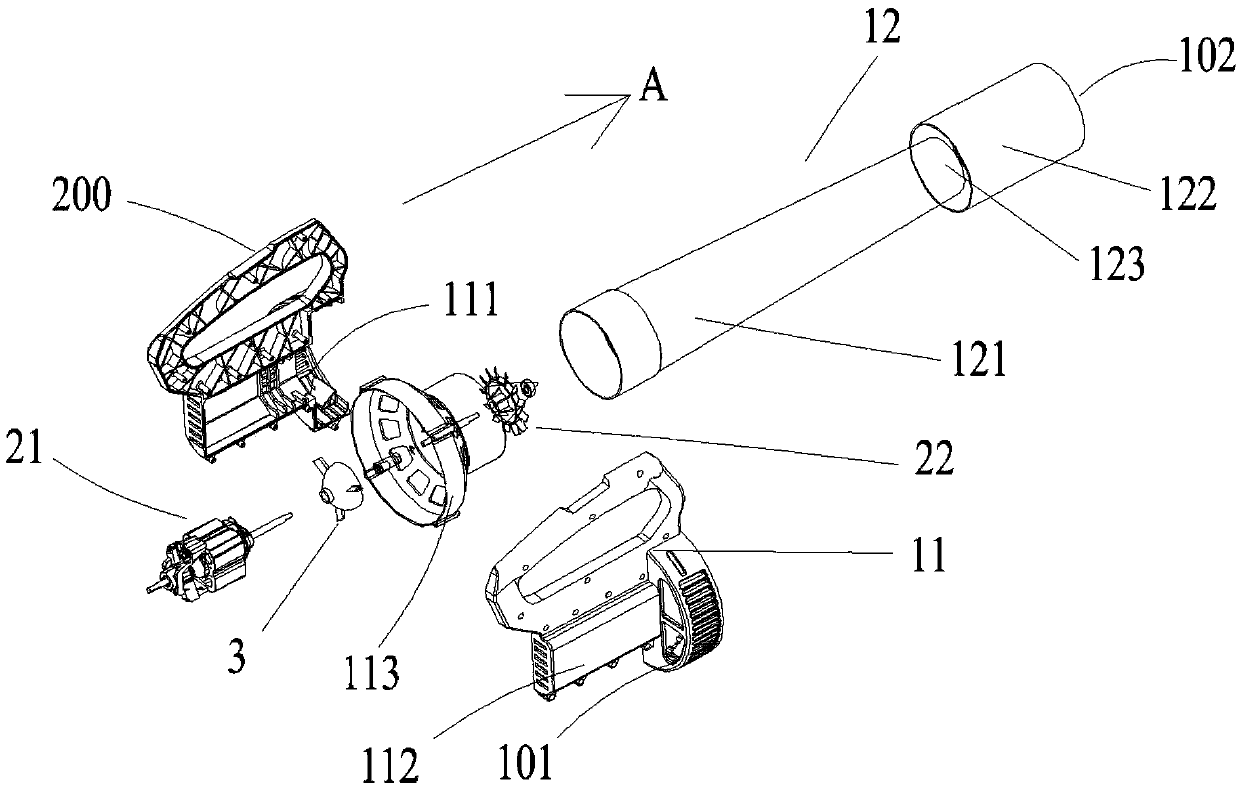

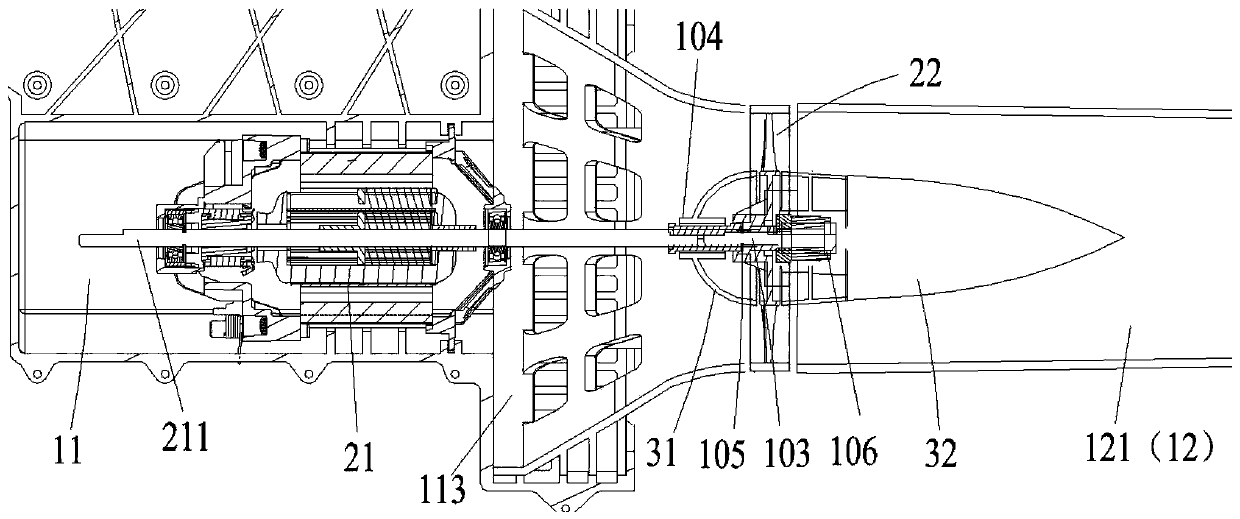

[0055] In this embodiment, the blowing pipe 1-12 includes a main blowing pipe 1-121 and a diffuser pipe 1-122 arranged separately, and a connecting part 1-123 is arranged at the front end of the main blowing pipe 1-121. Specifically, the motor 1-21 used is a high-speed motor with a rotational speed of 32000 RPM. Both the main blowpipe 1-121 and the diffuser pipe 1-122 are obliquely tapered, wherein the main blowpipe 1-121 has a taper of 1.5°, a length of 680mm, and a diameter of 55-65mm. The cross-sectional area in the axial direction is It gradually decreases from the rear end to the front end; the taper of the diffuser pipe 1-122 is 1.8°, the length is 180 mm, and the diameter is 95-105 mm, and its cross-sectional area in the axial direction decreases gradually from the rear end to the front end. The length of the connecting portion 1-123 is 5 mm, that is, the length of the overlapping area between the diffuser pipe 1-122 and the main blow pipe 1-121 is 5 mm. Moreover, the ...

Embodiment 2

[0057] In this embodiment, the blowing pipe 2-12 includes a main blowing pipe 2-121 and a diffuser pipe 2-122 arranged separately, and the connecting part 2-123 is arranged at the front end of the main blowing pipe 2-121. Specifically, the motor 2-21 used is a high-speed motor with a rotational speed of 32000 RPM. Both the main blowpipe 2-121 and the diffuser pipe 2-122 are obliquely tapered, wherein the main blowpipe 2-121 has a taper of 1.5°, a length of 680mm, and a diameter of 55-65mm. The cross-sectional area in the axial direction is It gradually decreases from the rear end to the front end; the taper of the diffuser pipe 2-122 is 1.8°, the length is 180 mm, and the diameter is 95-105 mm, and its cross-sectional area in the axial direction decreases gradually from the rear end to the front end. The length of the connecting portion 2-123 is 20mm, that is, the length of the overlapping area between the diffuser pipe 2-122 and the main blowpipe 2-121 is 20mm. Moreover, the...

Embodiment 3

[0059] In this embodiment, the blowing pipe 3-12 includes a main blowing pipe 3-121 and a diffuser pipe 3-122 arranged separately, and the connecting part 3-123 is arranged at the front end of the main blowing pipe 3-121. Specifically, the motor 3-21 used is a high-speed motor with a rotational speed of 32000 RPM. Both the main blowpipe 3-121 and the diffuser pipe 3-122 are obliquely tapered, wherein the main blowpipe 2-121 has a taper of 1.5°, a length of 680mm, and a diameter of 55-65mm. It gradually decreases from the rear end to the front end; the taper of the diffuser pipe 3-122 is 1.8°, the length is 180mm, and the diameter is 95-105mm, and its cross-sectional area in the axial direction decreases gradually from the rear end to the front end. The telescopic assembly 3-4 is arranged on the connecting portion 3-123 and connected to the diffuser pipe 3-122, and the diffuser pipe 3-122 has no overlapping area with the main blow pipe 3-121. The diffuser pipe 3-122 can shrink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com