Patents

Literature

284 results about "Co operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

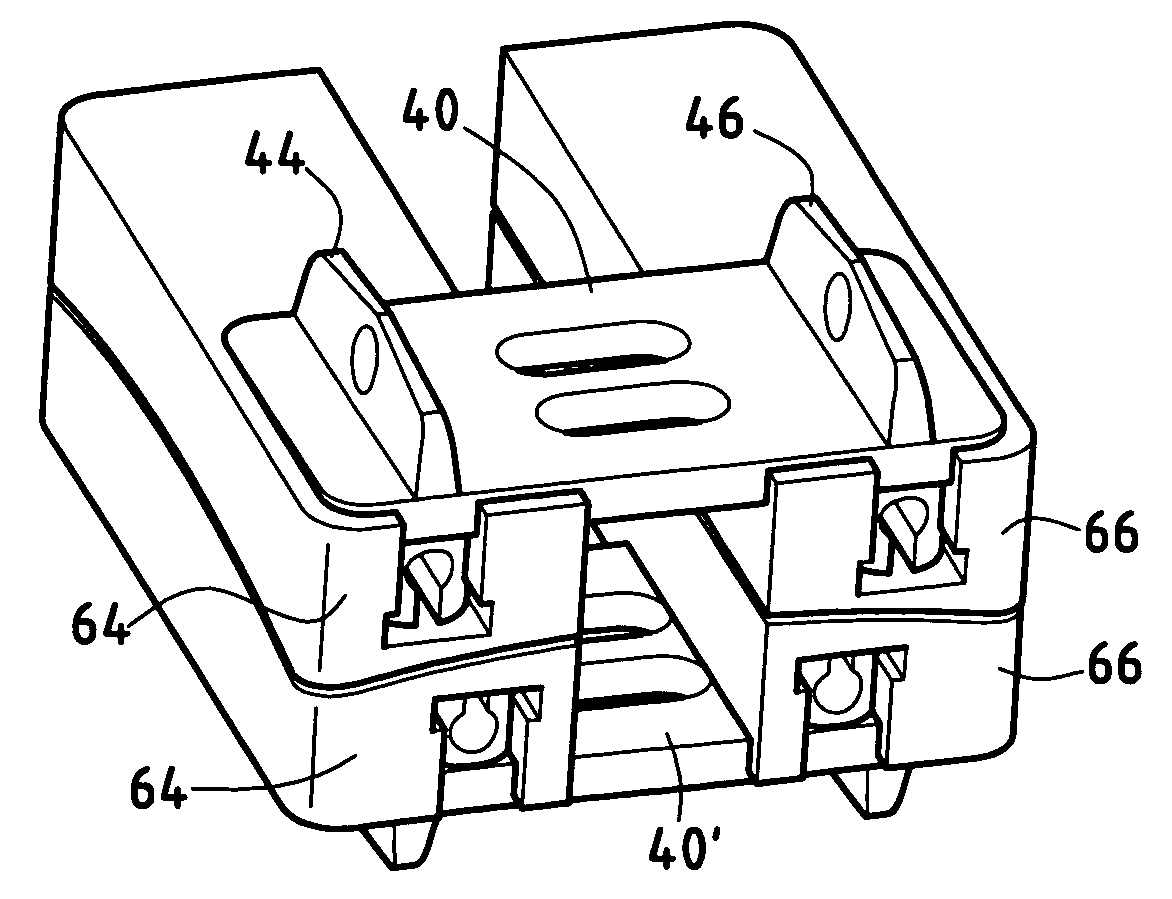

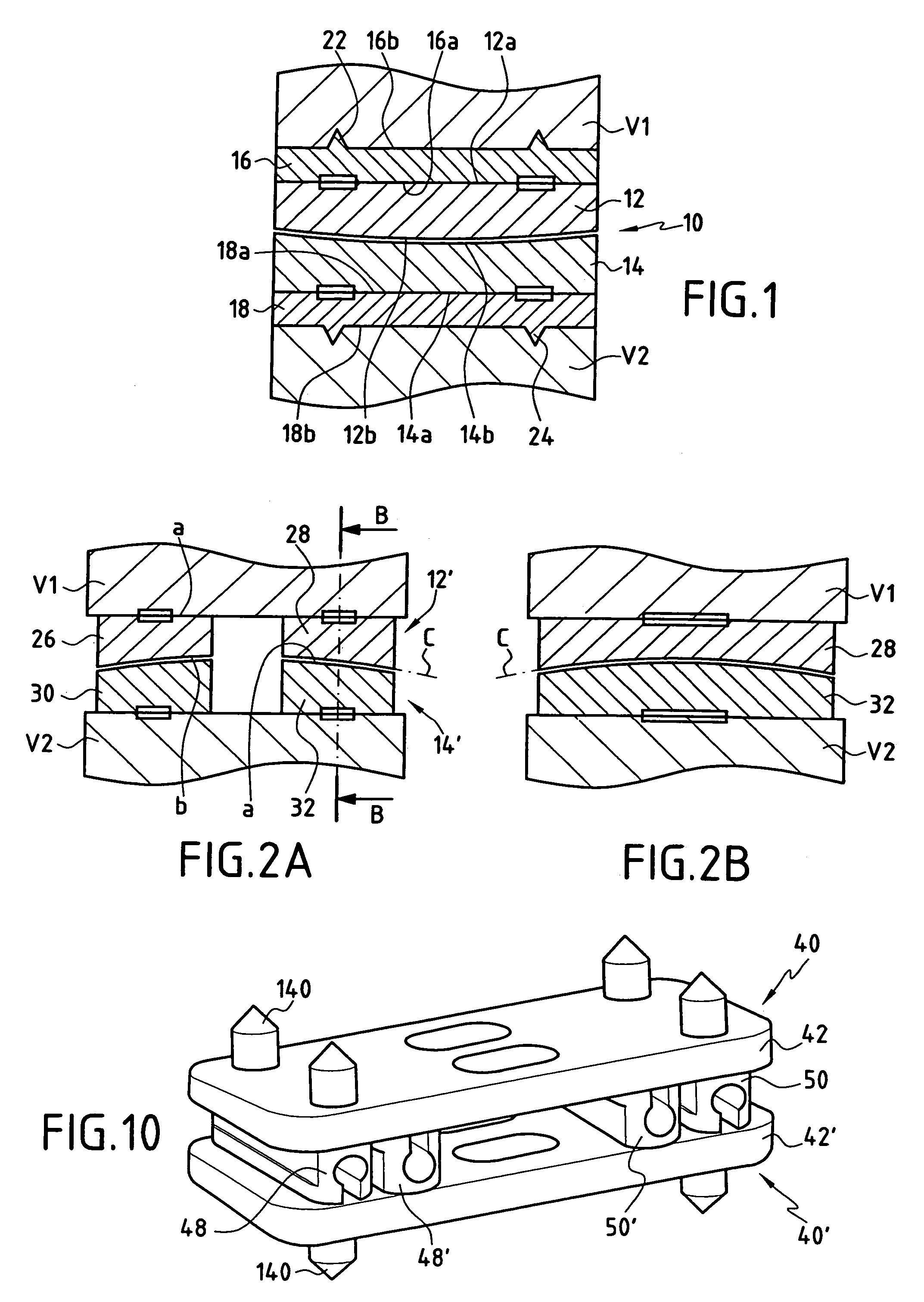

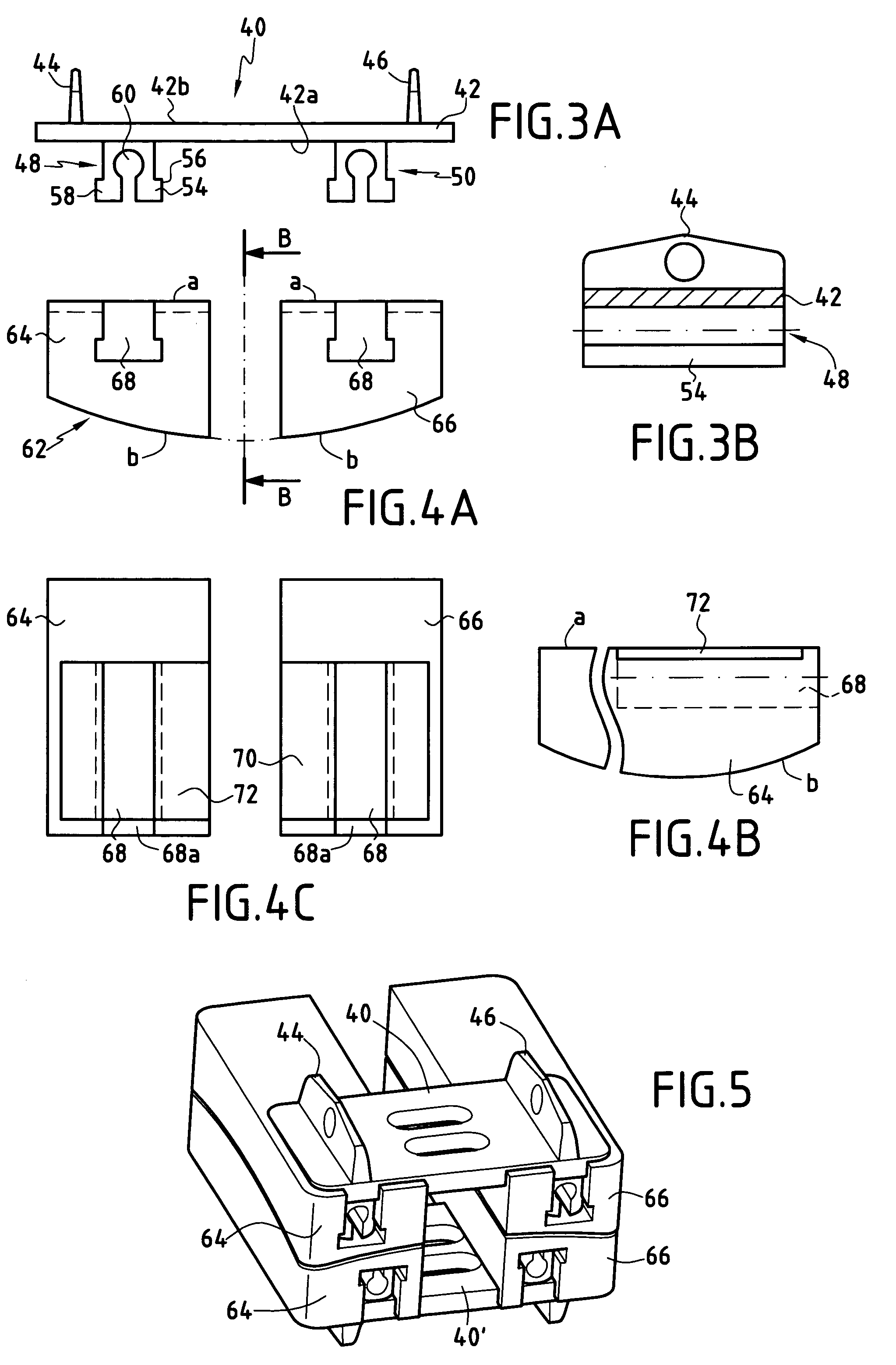

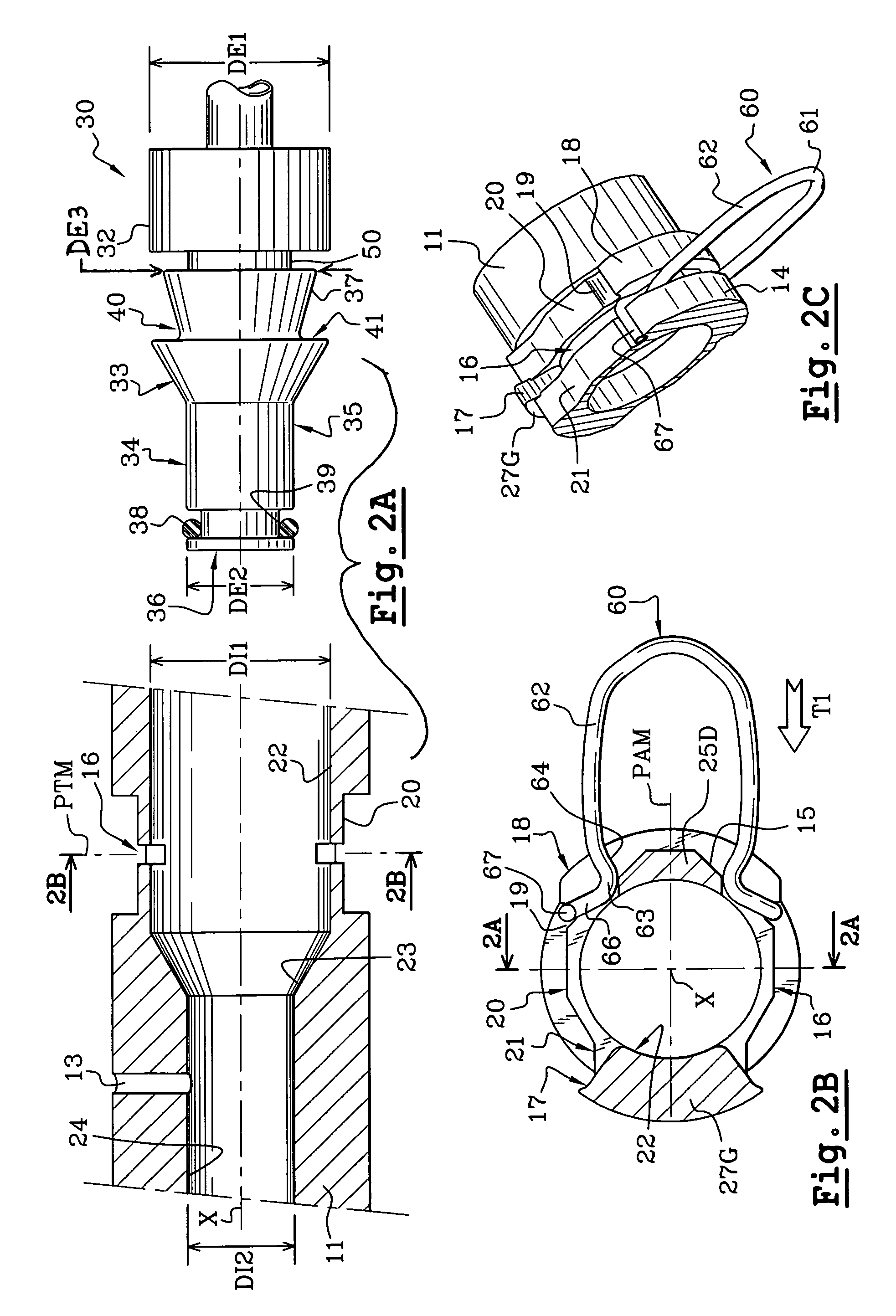

Intervertebral disk prosthesis

ActiveUS7611538B2Provides large amountEasy to placeJoint implantsSpinal implantsIntervertebral diskSpherical form

The invention provides an intervertebral disk prosthesis. The prosthesis comprises:a first fixing element having both an anchoring first face for anchoring in one of the vertebrae and a co-operation second face;a second fixing element having both an anchoring first face for anchoring in the other vertebrae and a co-operation second face;a first prosthesis element having both an active first face and a co-operation second face, said co-operation faces of the first fixing element and of the first prosthesis element serving to fasten the two elements together;a second prosthesis element having both an active first face and a co-operation second face, said co-operation faces of the second fixing element and of the second prosthesis element serving to fasten the two elements together; andeach of said active faces of the prosthesis elements defining at least a portion of a spherical cap that is respectively concave or convex.

Owner:ABBOTT SPINE INC

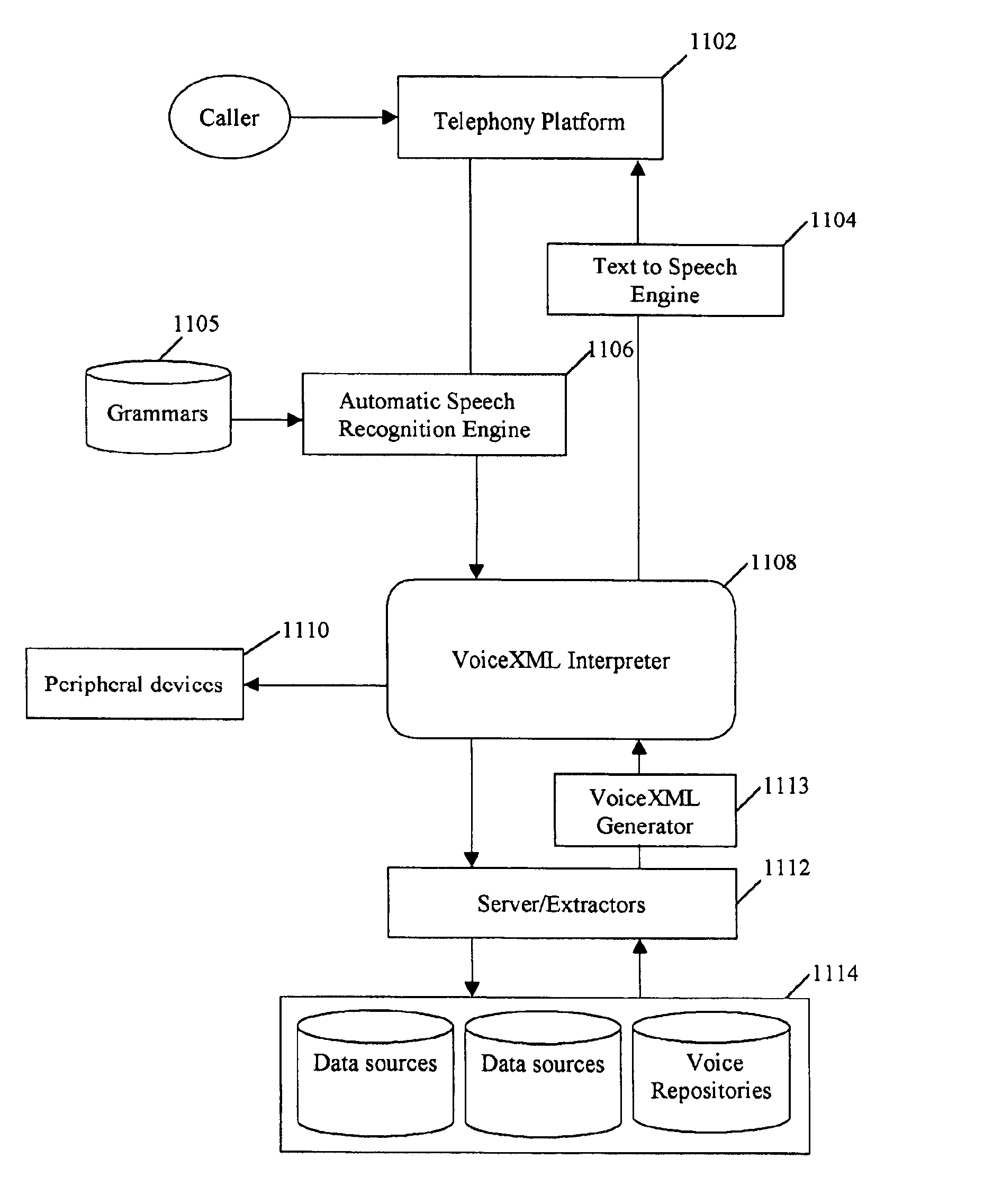

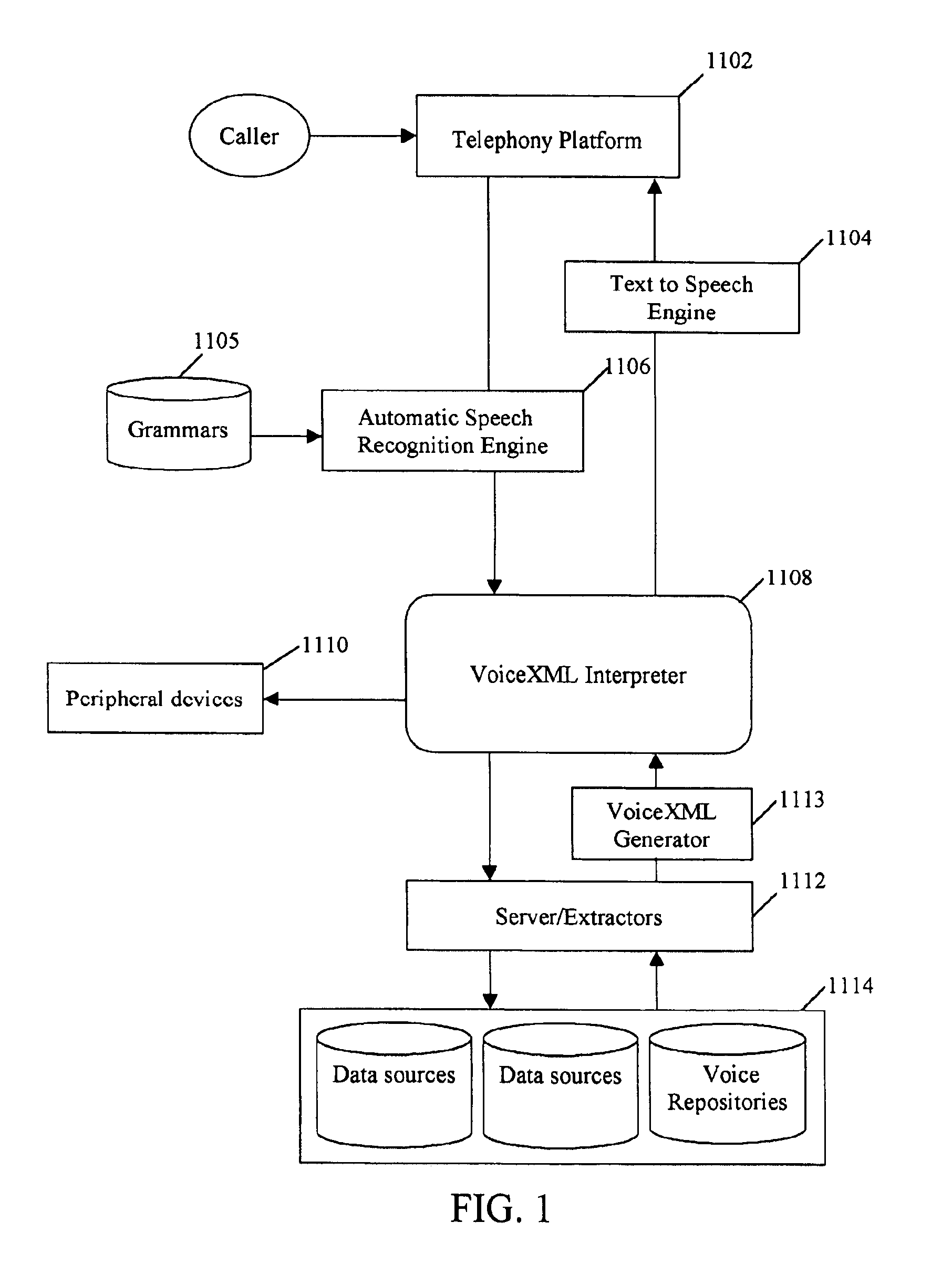

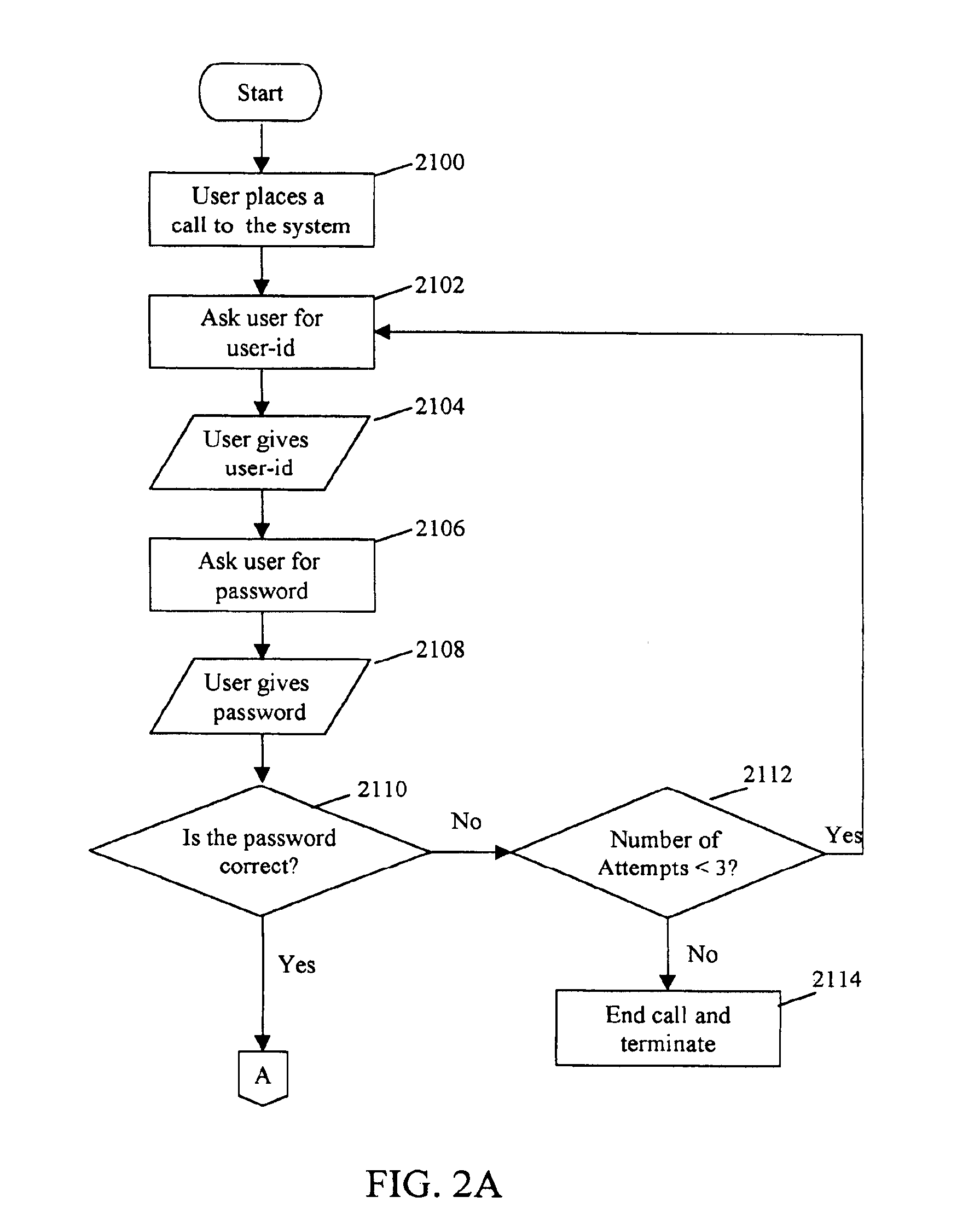

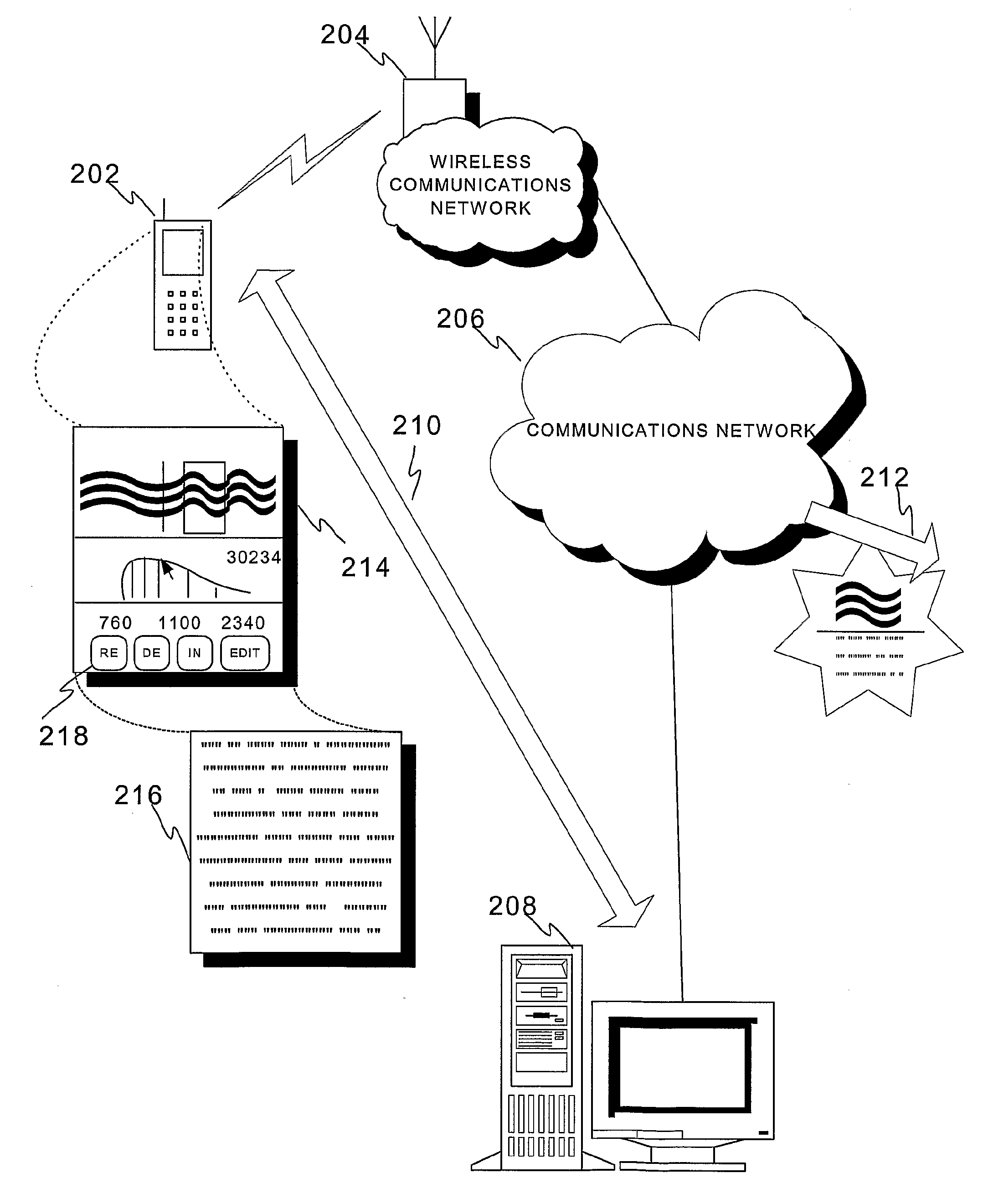

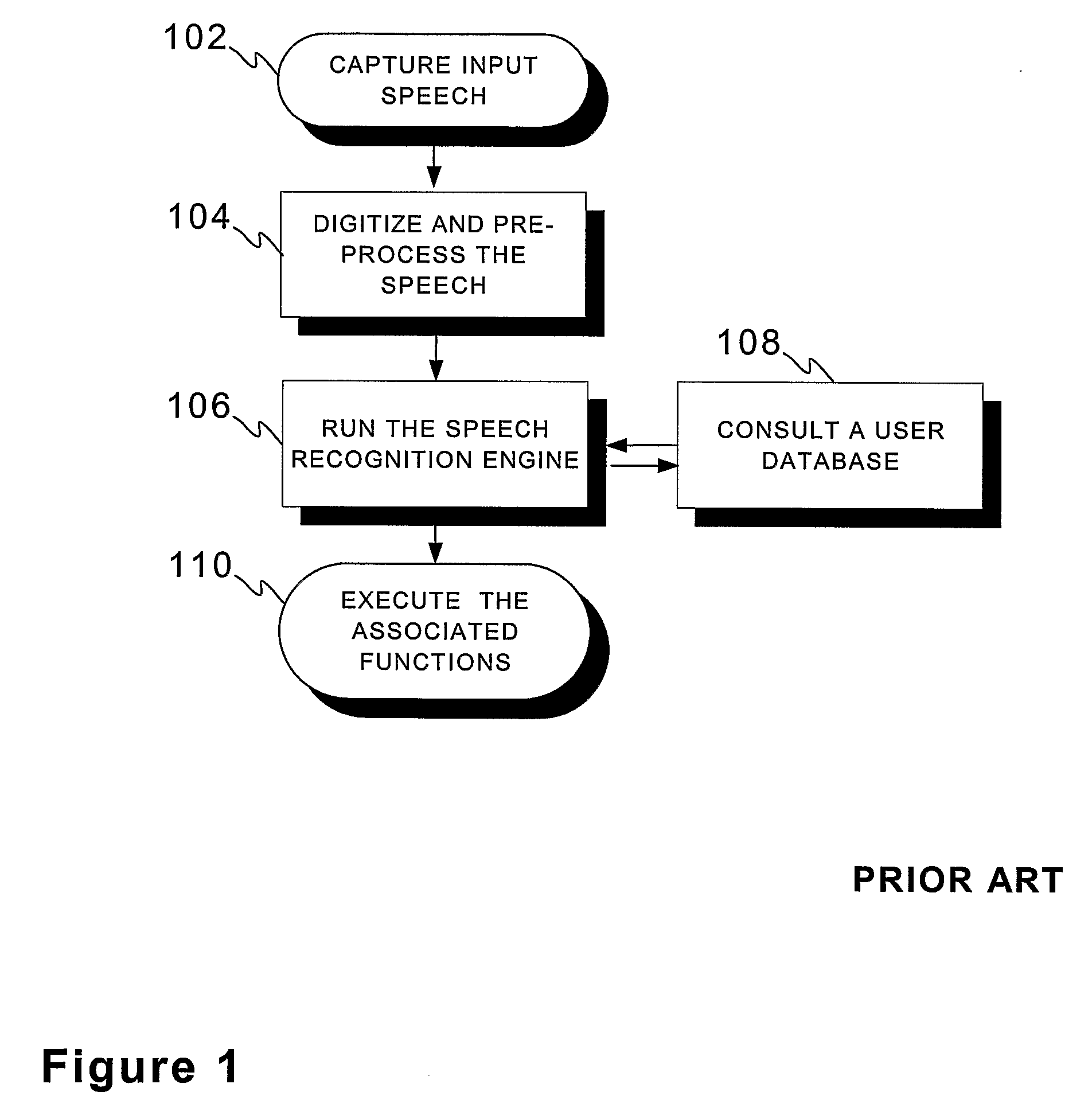

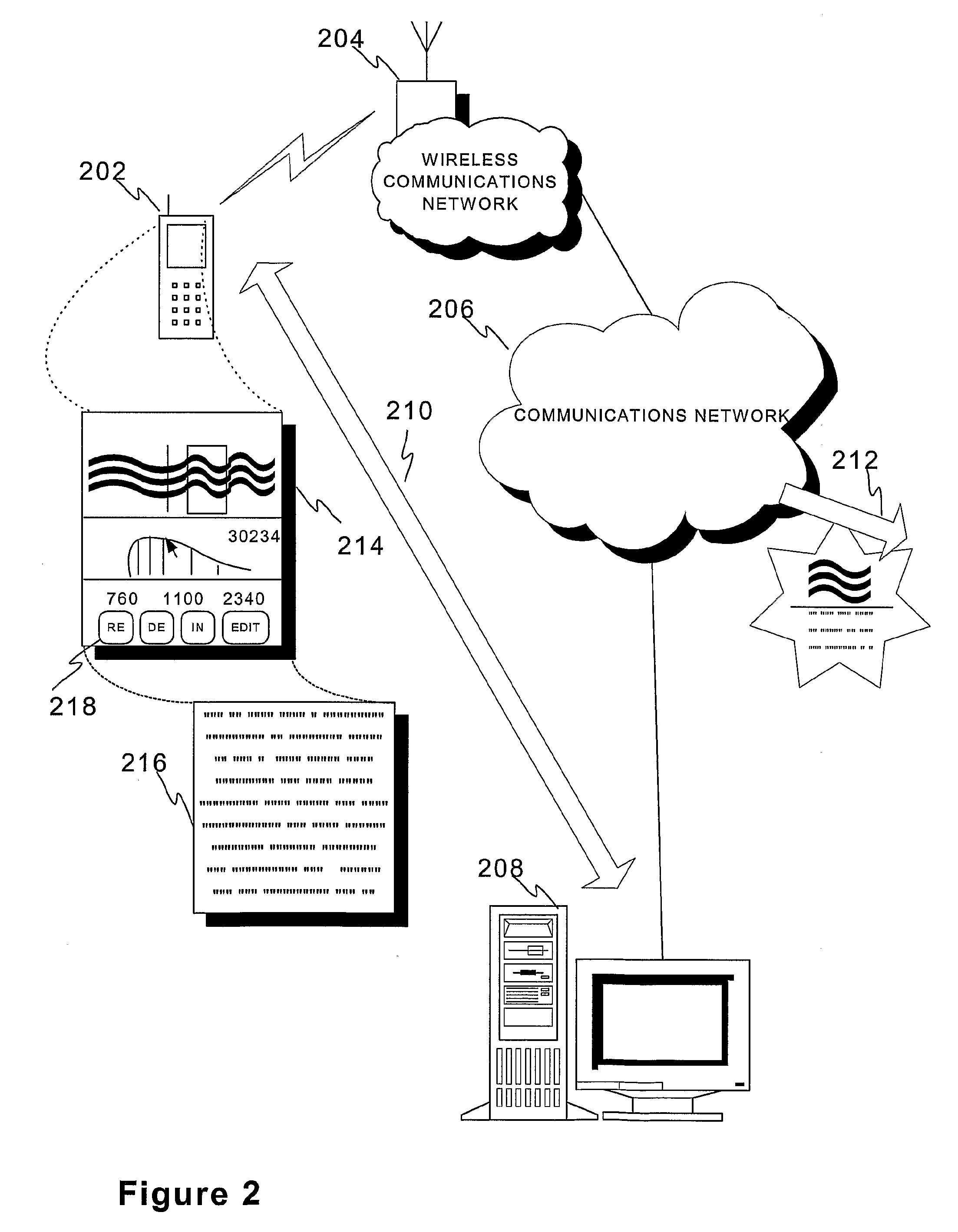

System and methodology for voice activated access to multiple data sources and voice repositories in a single session

InactiveUS6891932B2Automatic call-answering/message-recording/conversation-recordingMultiple digital computer combinationsSingle sessionData source

A system and method and computer program for seamlessly accessing multiple data sources and voice repositories using voice commands in a single phone call session. The system comprises of voice grammars that span various contexts for all data sources and voice repositories, a telephony platform, an automatic speech recognition engine, extractors for extracting information from the data sources and voice repositories and an interpreter for controlling the extractors and telephony platform. It is the co-operation between the voice grammars and the telephony platform, controlled by a VoiceXML interpreter that enables this seamless access to information from the multiple data sources and voice repositories.

Owner:CISCO TECH INC

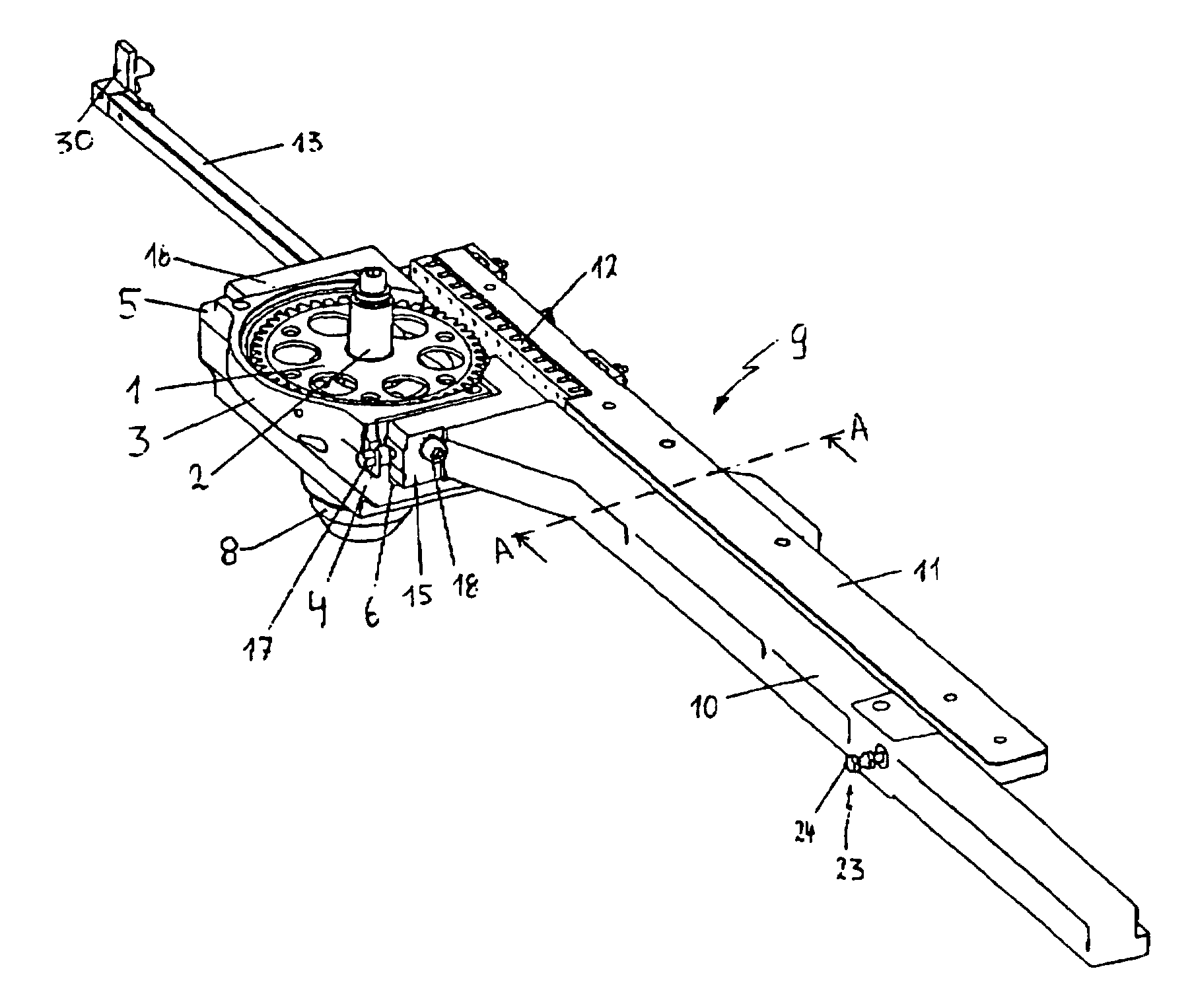

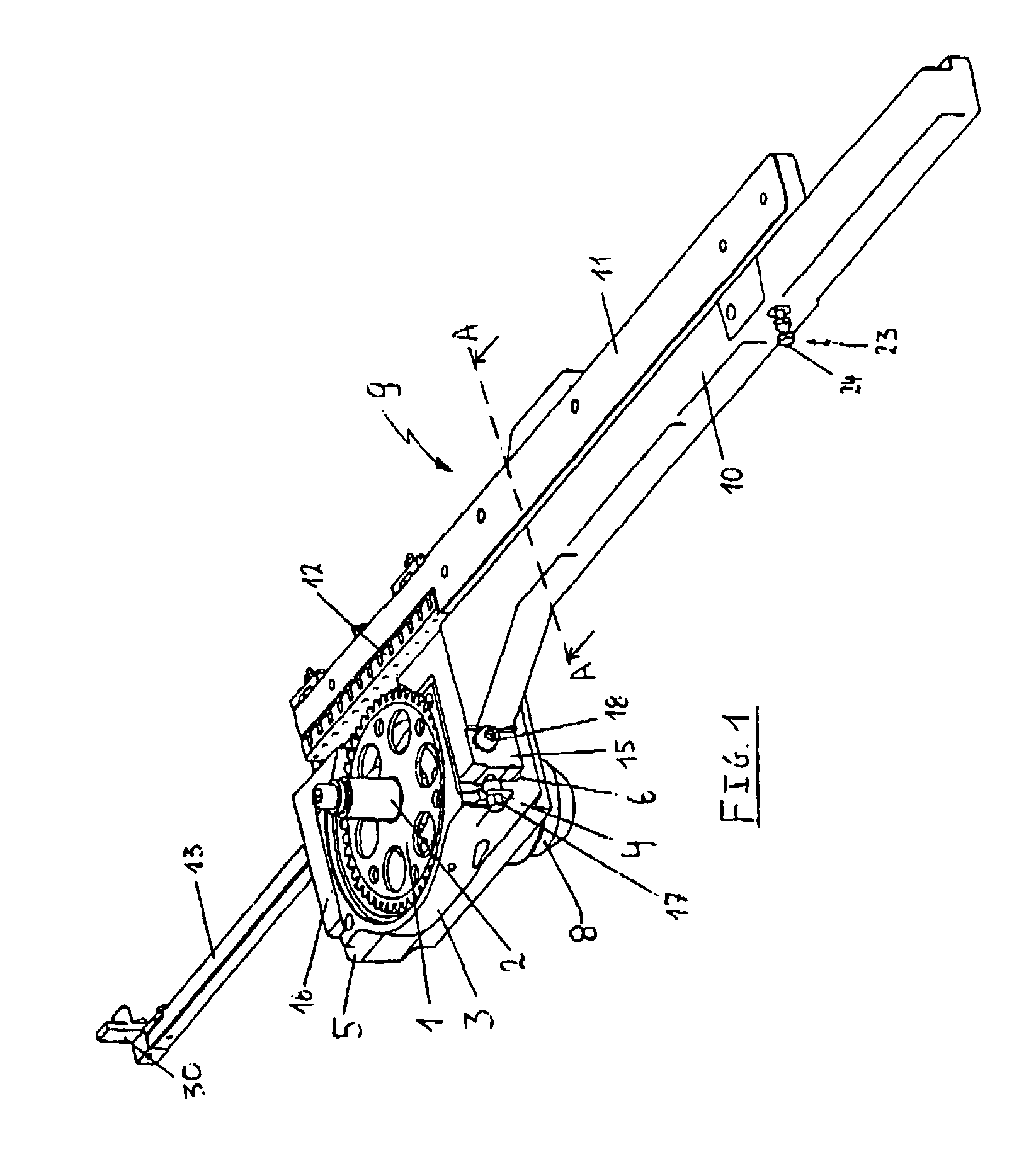

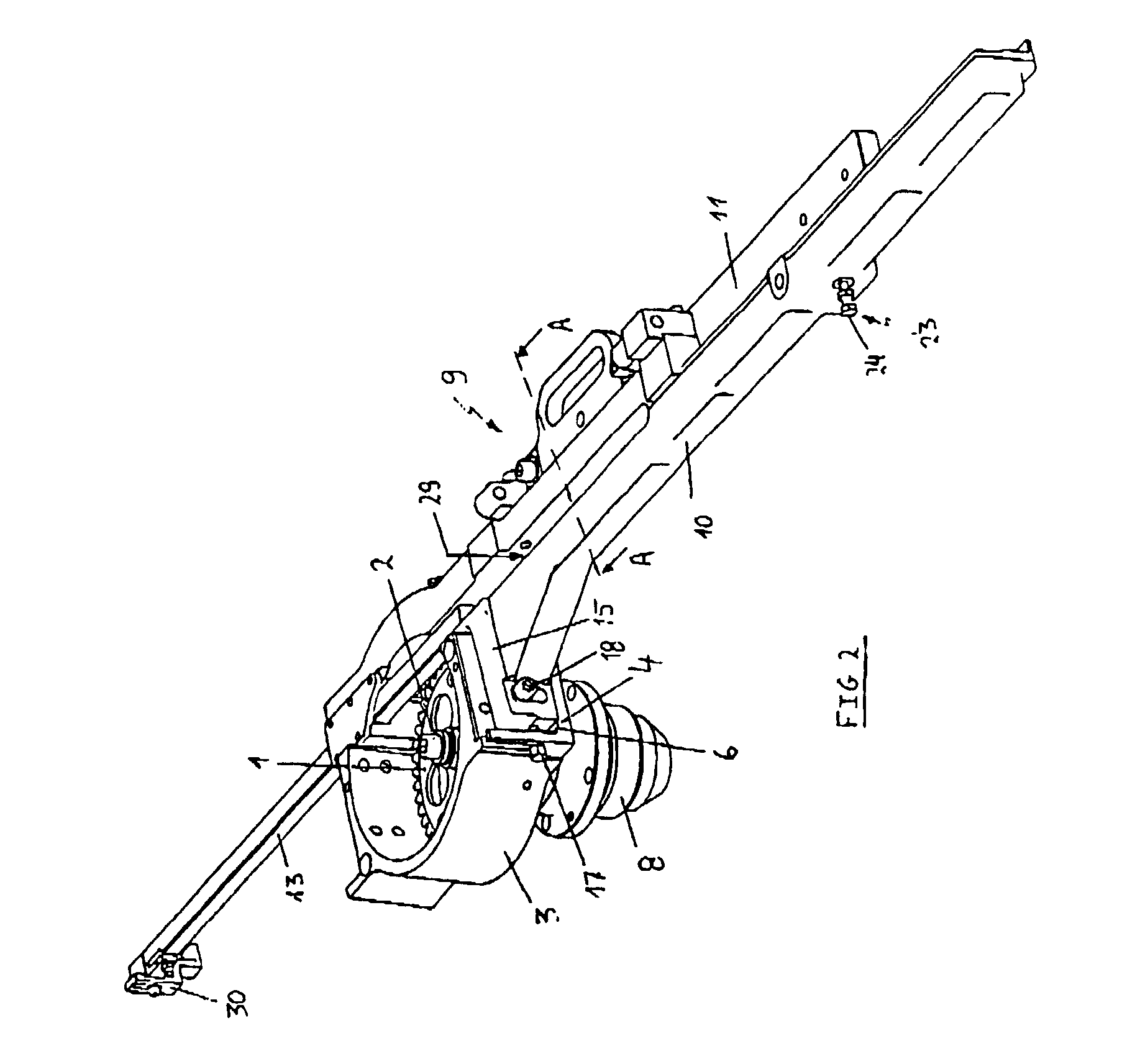

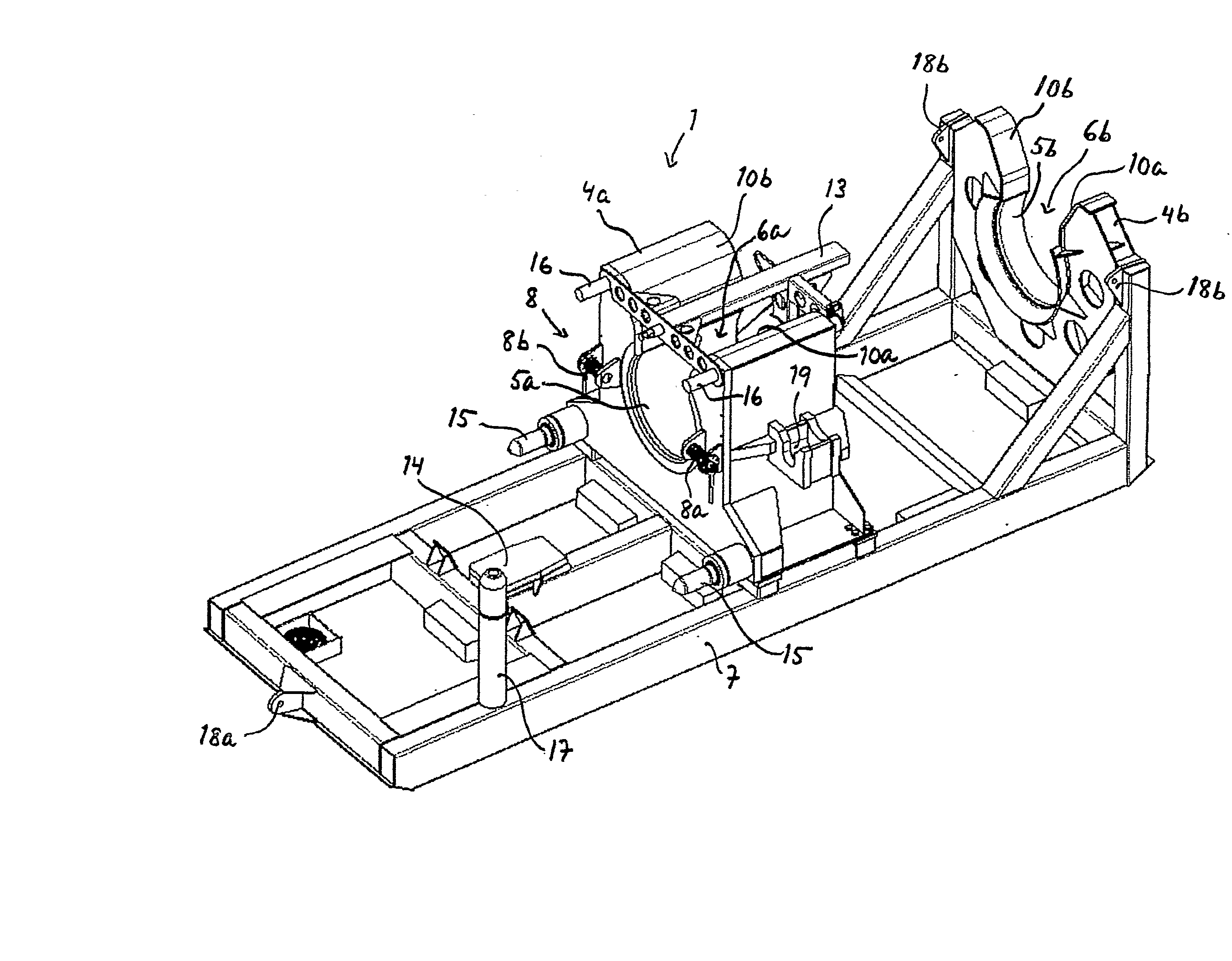

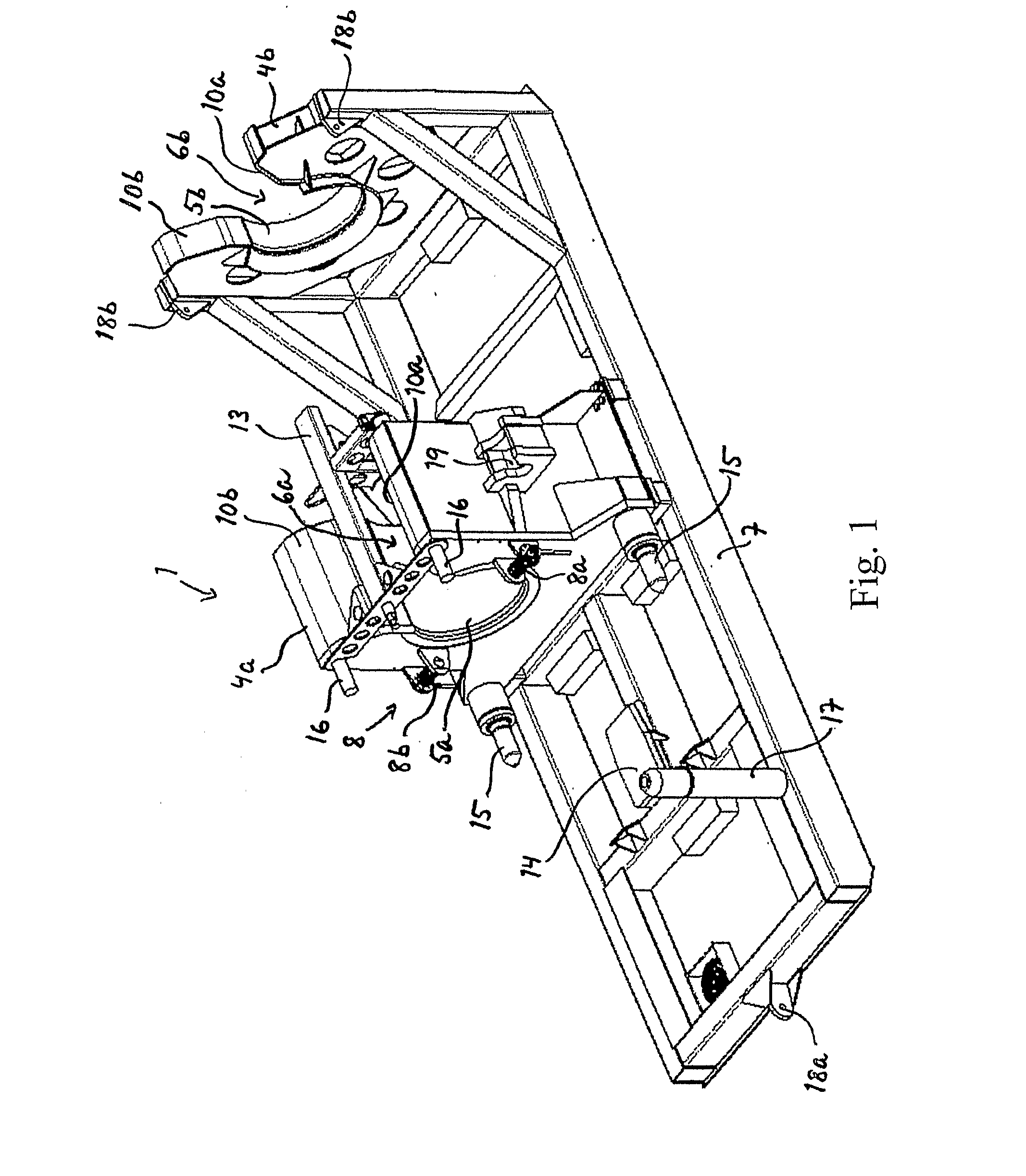

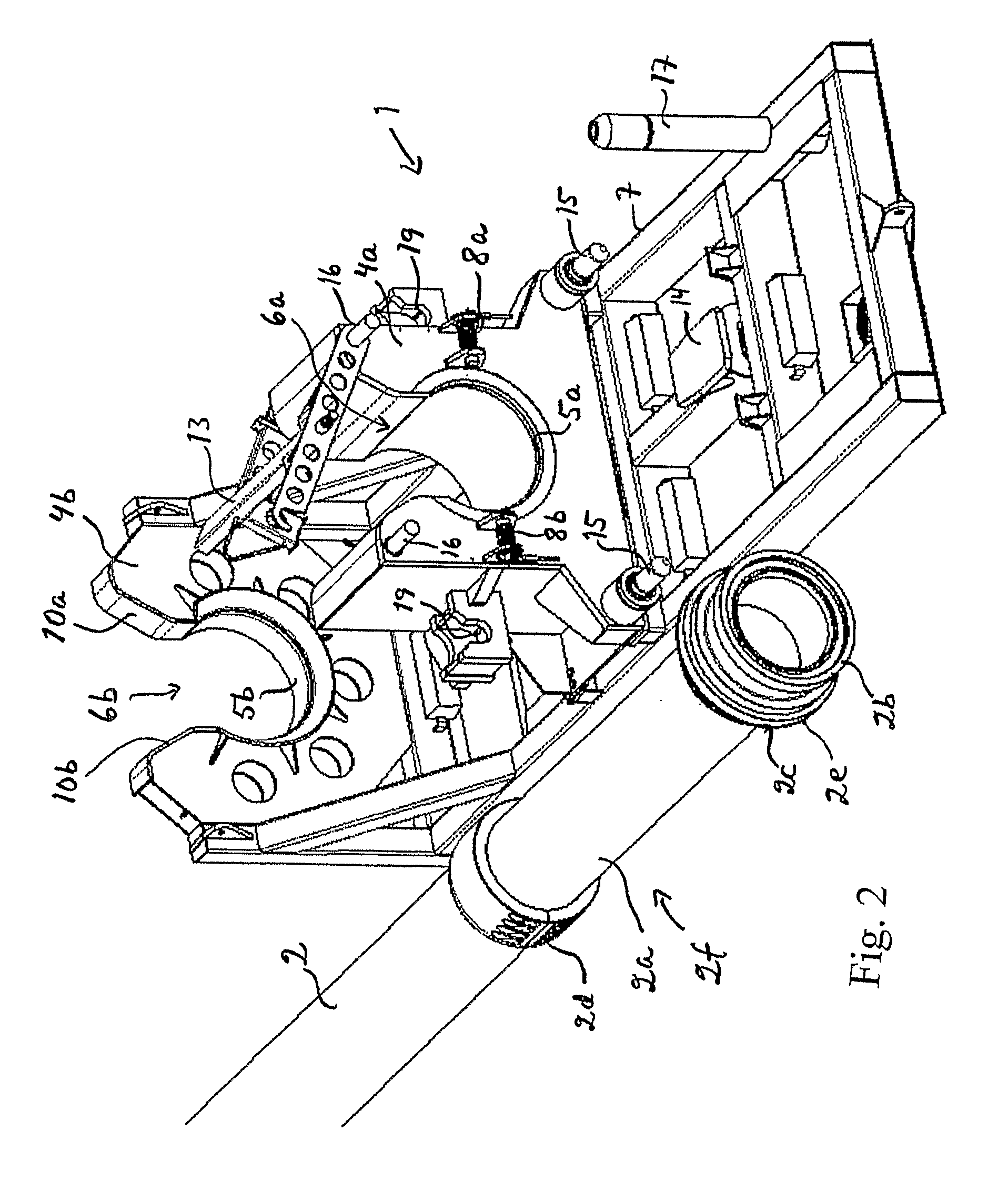

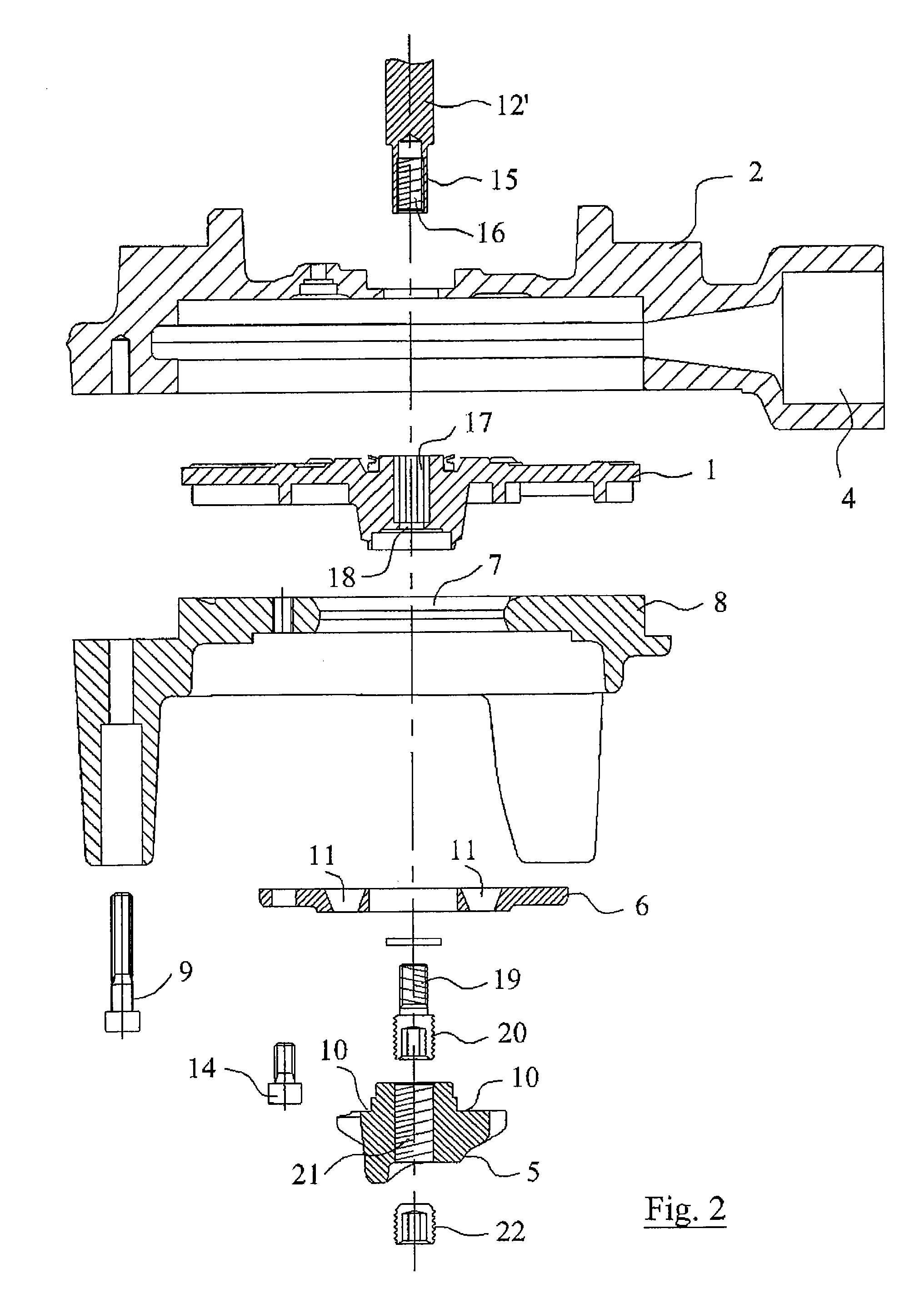

Device for driving and guiding a rapier of a weaving machine

A device for driving and guiding a rapier of a weaving machine, comprises a rotatable drive wheel (1) provided for driving a rapier rod (14) in a back and forth movement and a guide channel formed by adjustable guide bodies (10), (11) in order to guide the said rapier rod (14) according to a guide path in co-operation with the drive wheel (1). The guide bodies (10), (11) are part of a guide unit (9) which, as a whole, is adjustable in order to modify the distance between the guide path and the rotation shaft (2) of the drive wheel (1), and where the drive wheel (1) is continuously adjustable in the longitudinal direction of its shaft (2). With this device the clearances of the rapier rod with respect to the drive wheel can be performed easily, rapidly and with great precision, so that this device is able to work with a minimum development of heat and wear.

Owner:N V MICHEL VAN DE WIELE

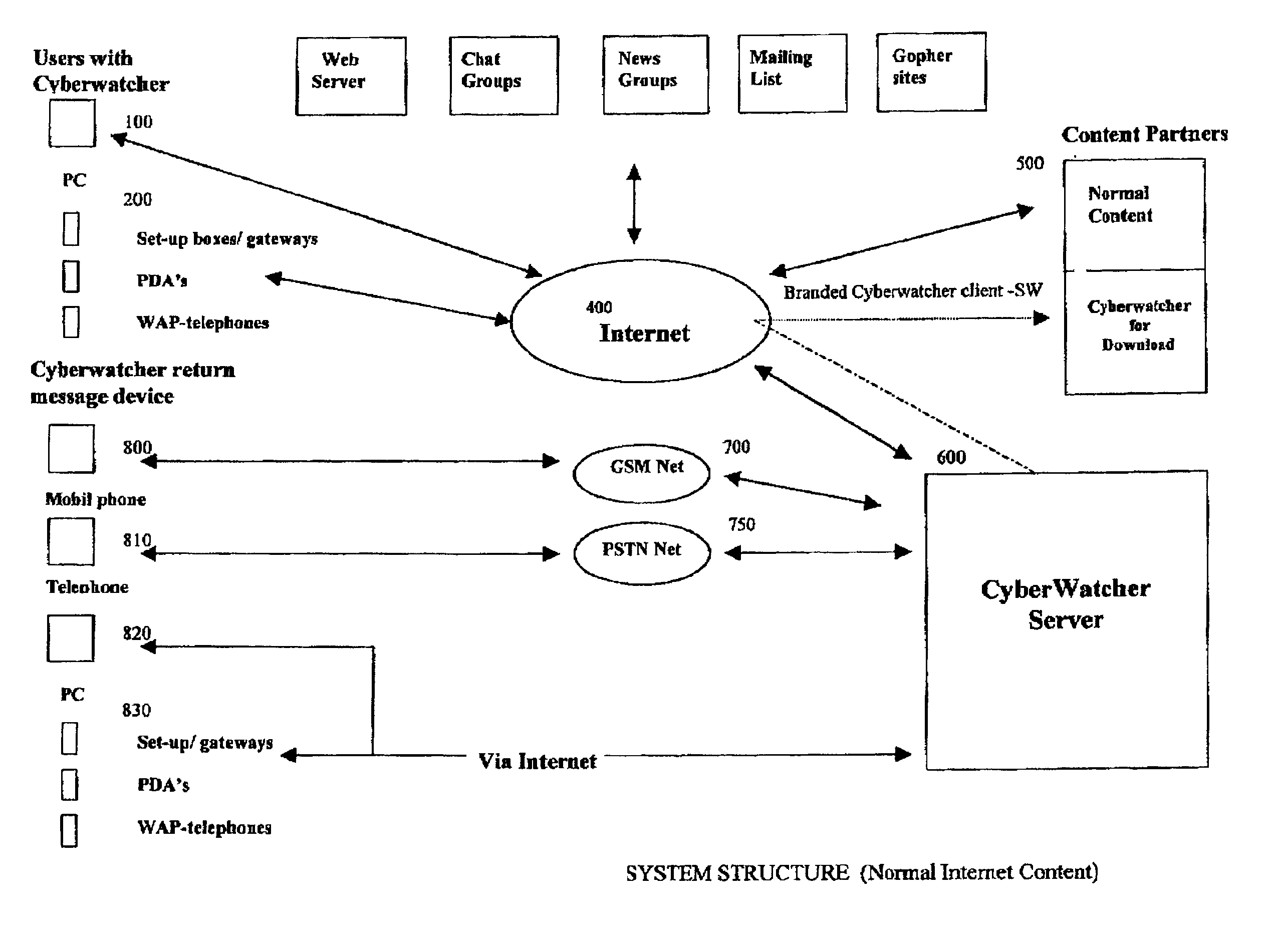

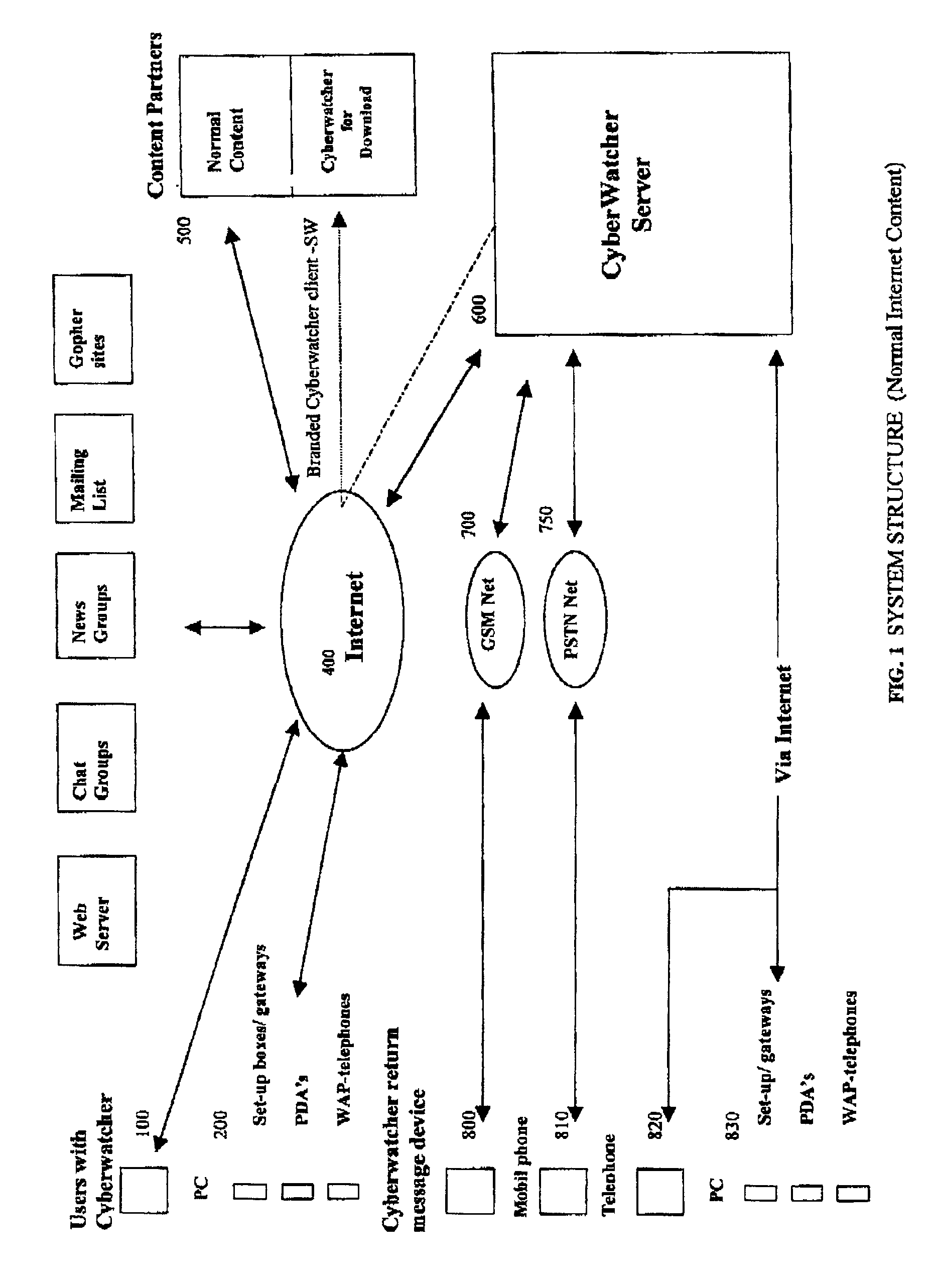

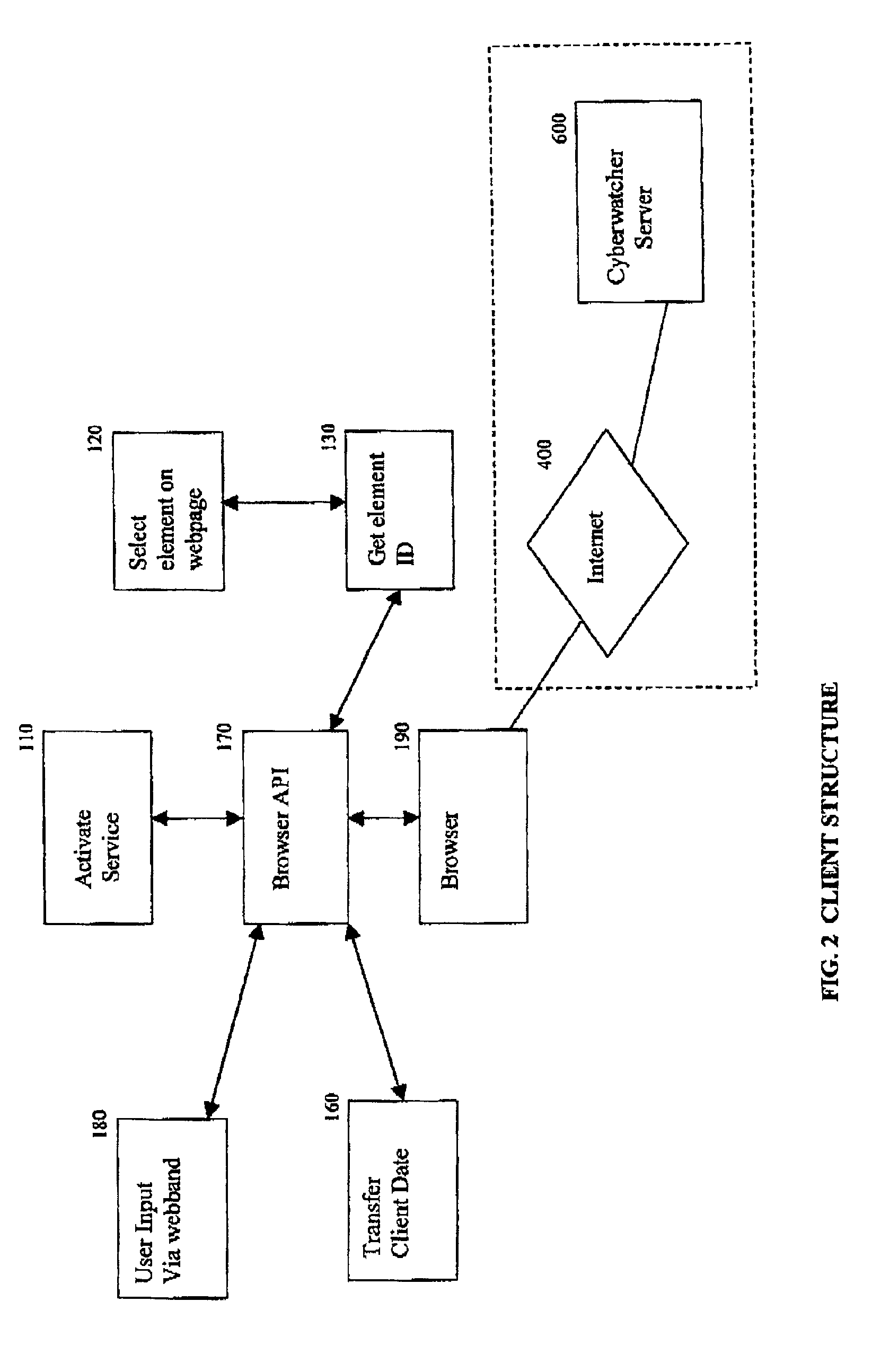

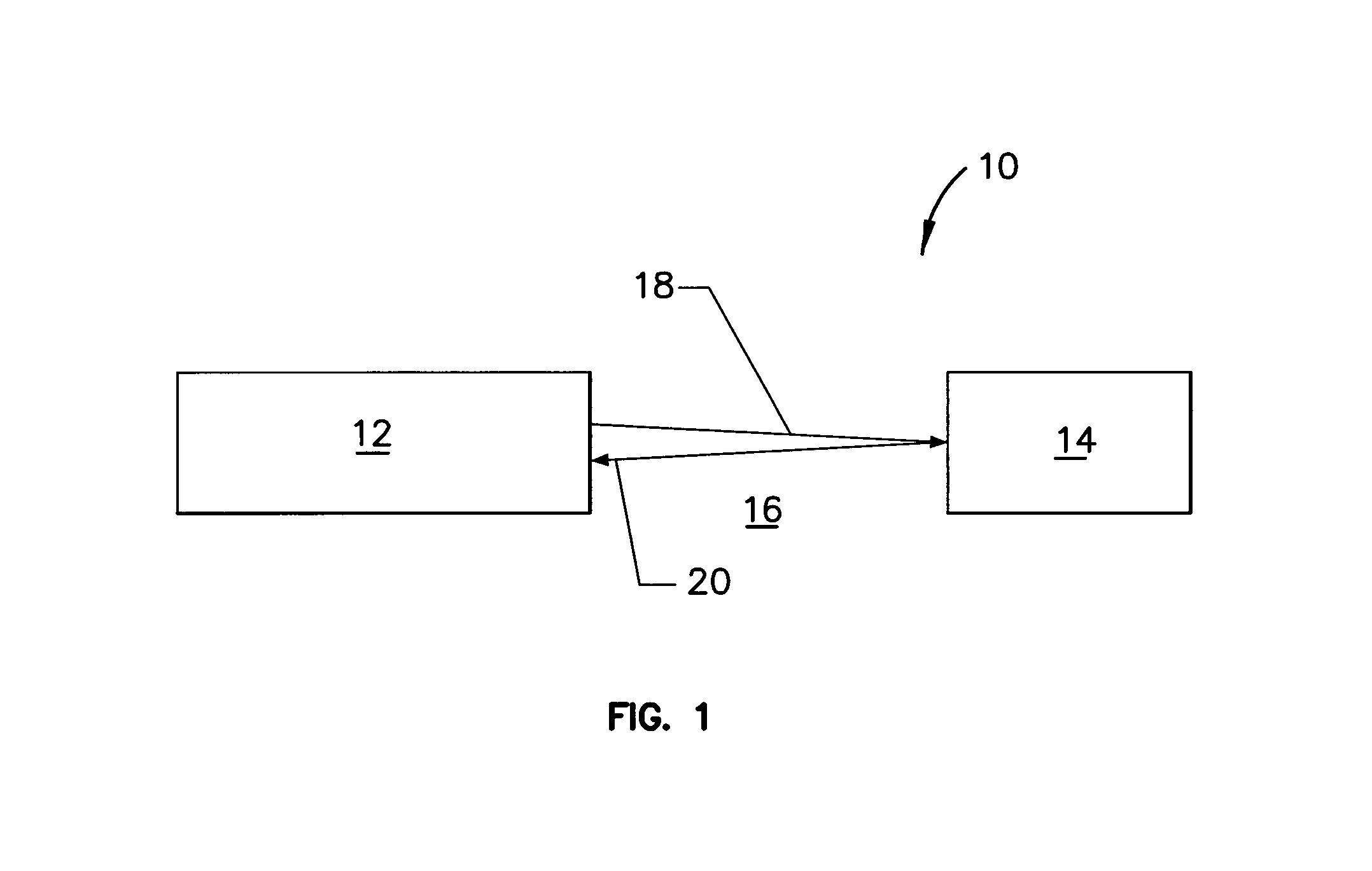

Method and arrangement for web information monitoring

InactiveUS6915482B2Data processing applicationsDigital computer detailsInformation objectClient-side

A method and arrangement in a computer client / server constellation provides a web page information element monitoring service to a subscribing user. The client part (100) in co-operation with the first browser, operated by the user, acquires a user specified web page, generates a position specifying unique first ID on basis of a user selected first information object contained on the web page, and transfers the first ID to the server part (600). The server part (600), in co-operation with a second browser, reacquires the web page and generates a second unique ID on basis of a second information object found at a position provided by the first ID, and generates a change indicator if the second ID is different from the first ID. The change indicator triggers a notification of the detected change to the subscribing user.

Owner:OL SECURITY LIABILITY CO

Stand for displaying articles, such as flat-packed articles

InactiveUS7717276B2Reduce manufacturing costEasy to operateRacksShow shelvesHand manoeuvreMechanical engineering

Owner:JOALPE IND DE EXPOSITORES

Pipeline Termination Skid, a Connection Arrangement Comprising Such a Pipeline Termination Skid and a Pipeline Termination

ActiveUS20070269270A1Facilitate pipe-laying operationReduce demandPipe laying and repairFlanged jointsOcean bottomSlide plate

A pipeline termination skid to be mounted to a pipeline end section to support a pipeline hub during the connection of the pipeline hub to a corresponding spool piece hub. The pipeline termination skid is so designed that a pipeline end section may be mounted thereto subsea by lowering the pipeline end section into a seat of one or several holding devices of the pipeline termination skid and thereafter displacing the pipeline termination skid along the pipeline end section so that the respective seat is brought into engagement with an alignment element secured about the pipeline end section so as to thereby fix the pipeline end section axially and radially in relation to the pipeline termination skid. A connection arrangement includes the pipeline termination skid, a pipeline termination designed for co-operation with the termination skid and a method for subsea connection of a pipeline to a spool piece.

Owner:VETCO GRAY SCANDINAVIA

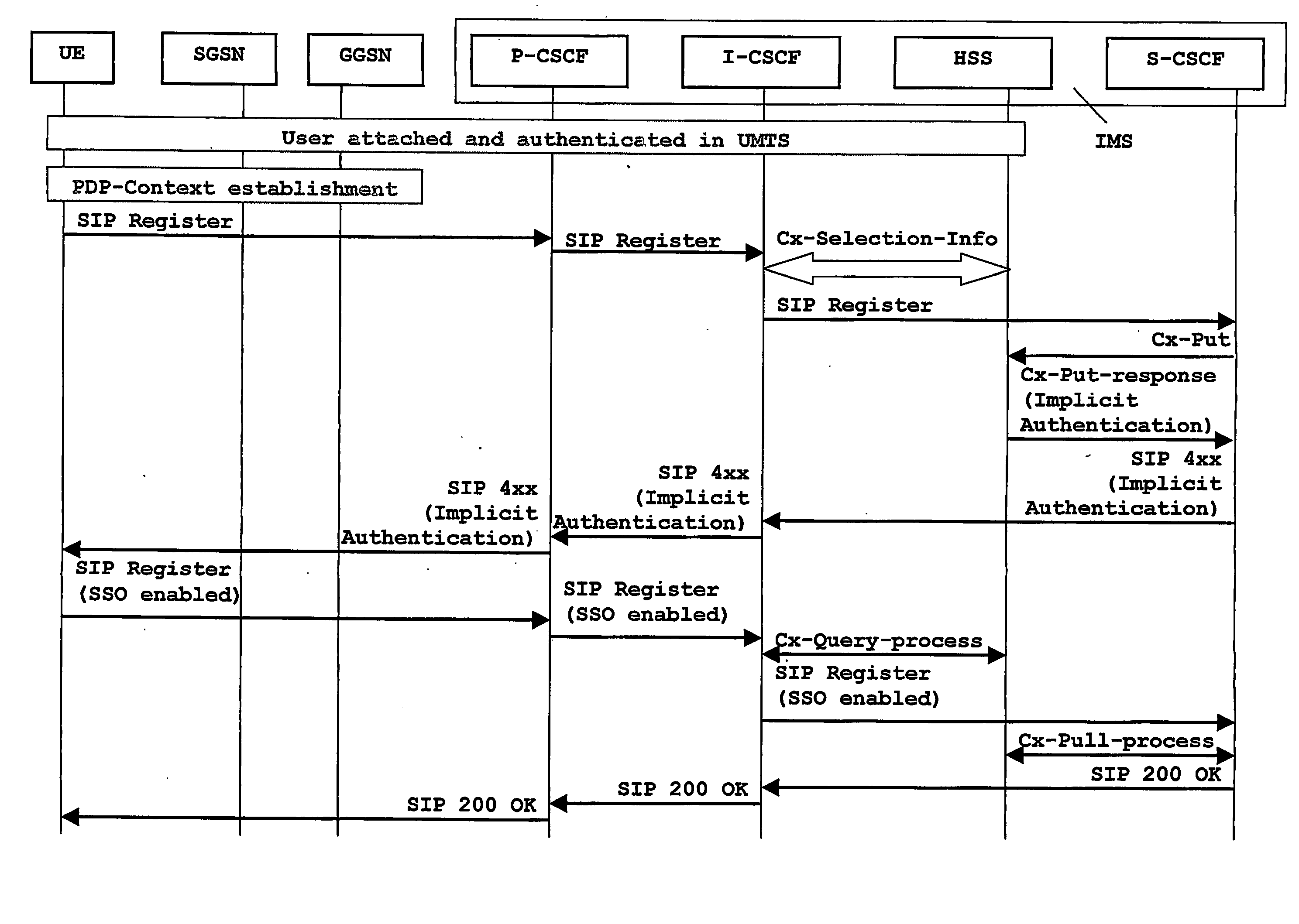

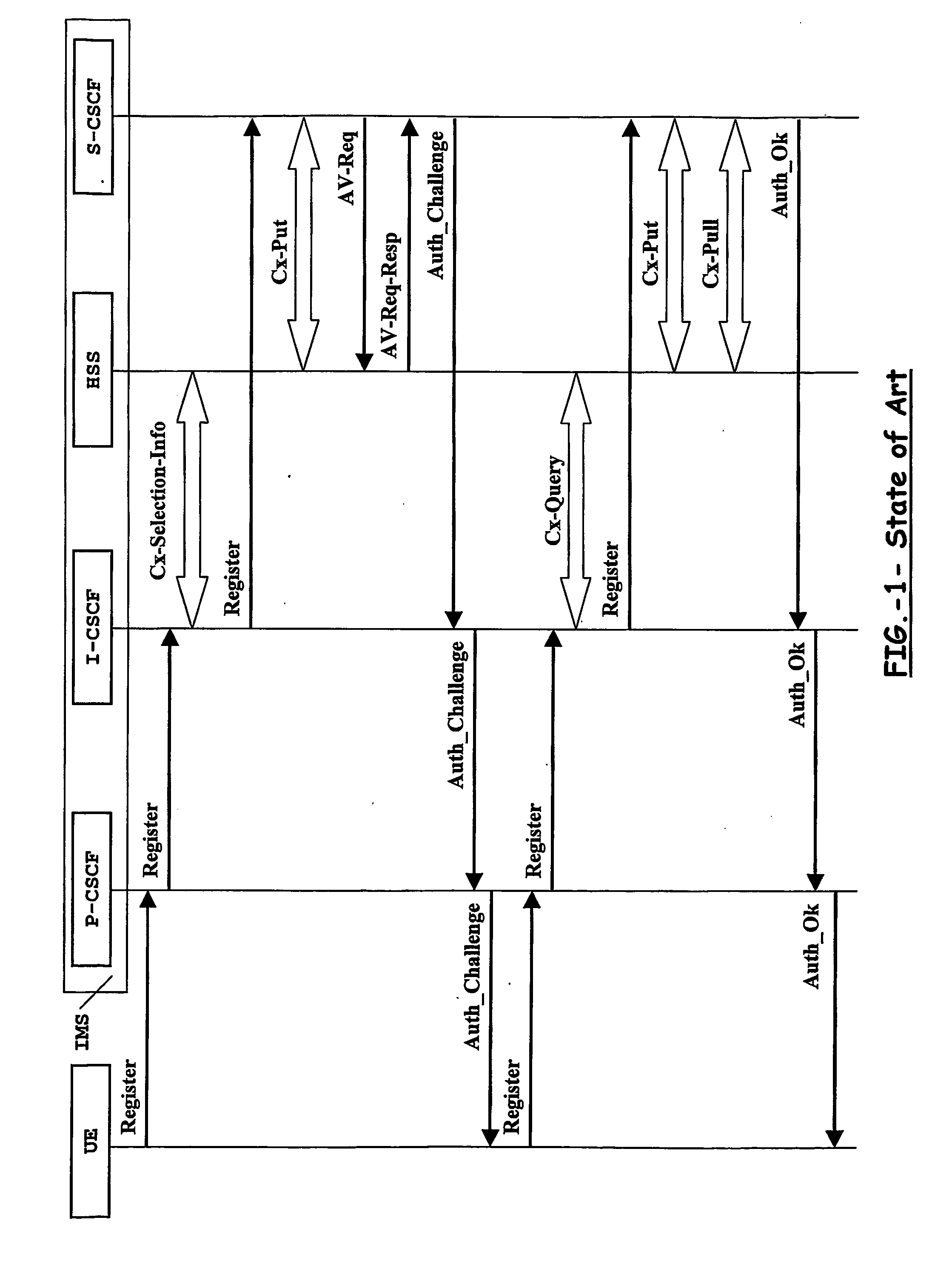

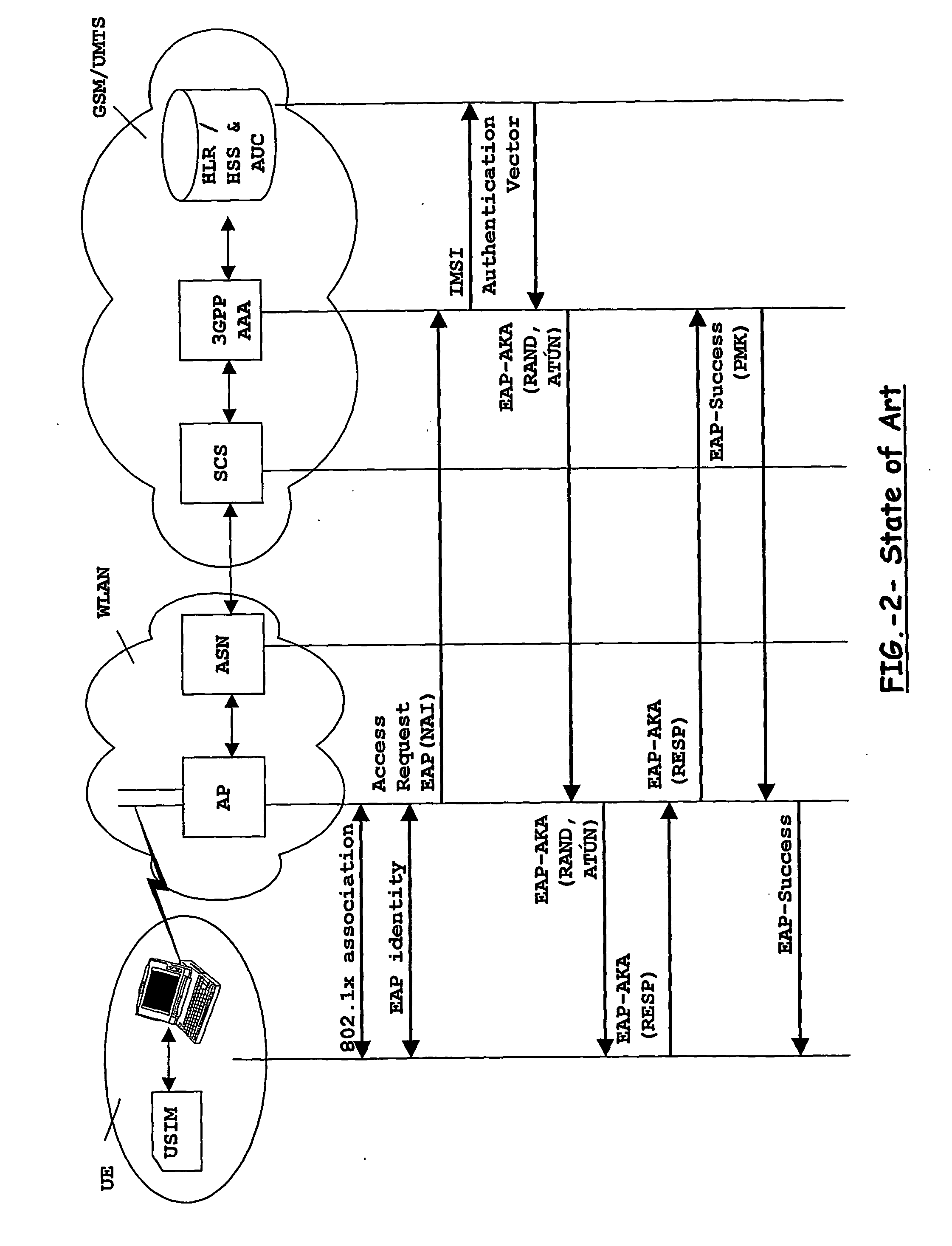

Apparatus and method for authenticating a user when accessing to multimedia services

An inter-domain authentication mechanism is provided for carrying out a cross-domain authentication for a given user between an access network domain and a Multimedia domain. The authentication mechanism is applicable where a user has been authenticated by the access network and may be implemented as a dedicated Multimedia Authentication device in close co-operation with a subscriber server, or be fully integrated in the subscriber server. The authentication mechanism is arranged for re-using authentication data between different networks, or between different technological domains, and with help from other entities of a Multimedia domain according to present standards.

Owner:TELEFON AB LM ERICSSON (PUBL)

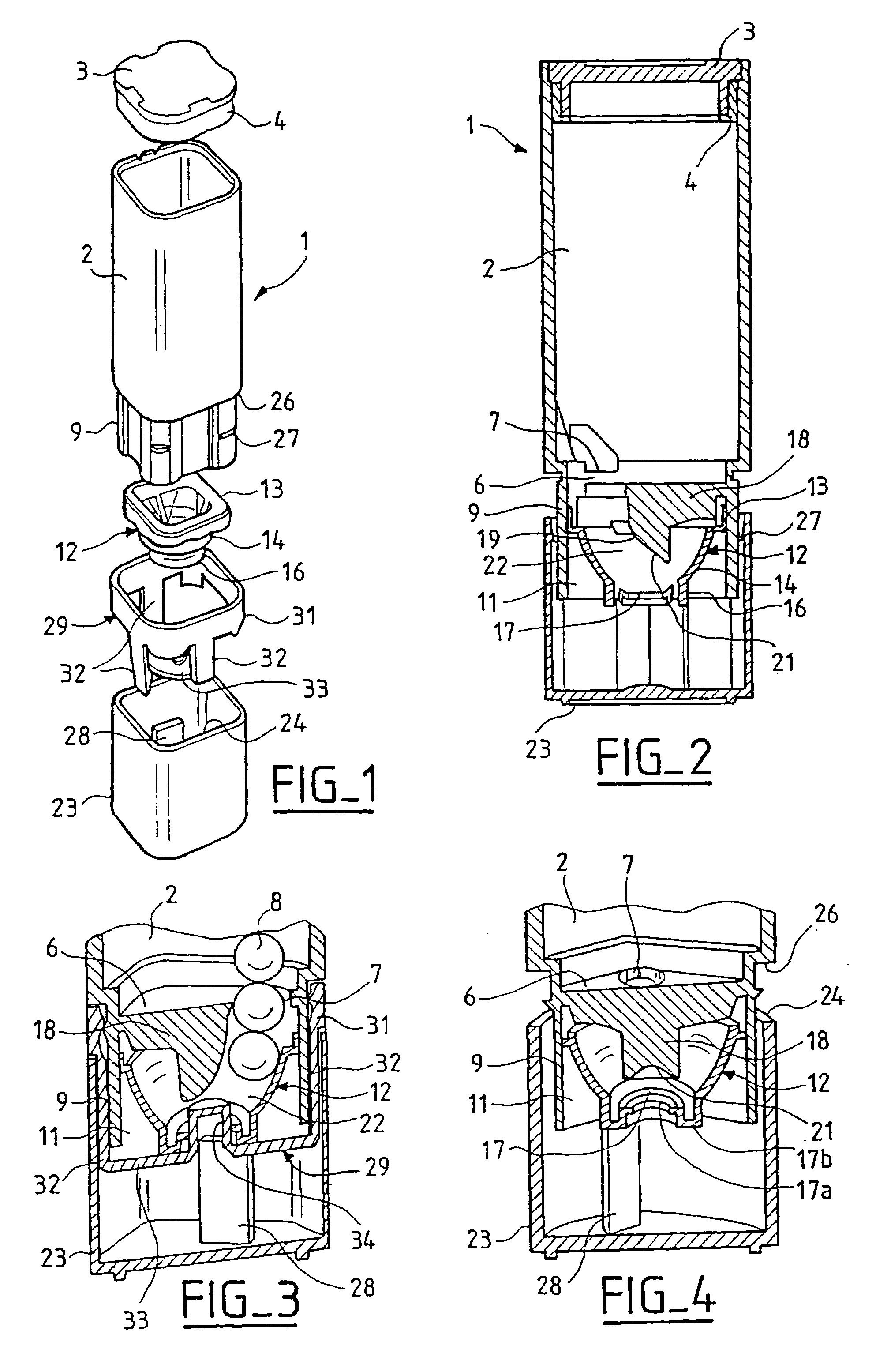

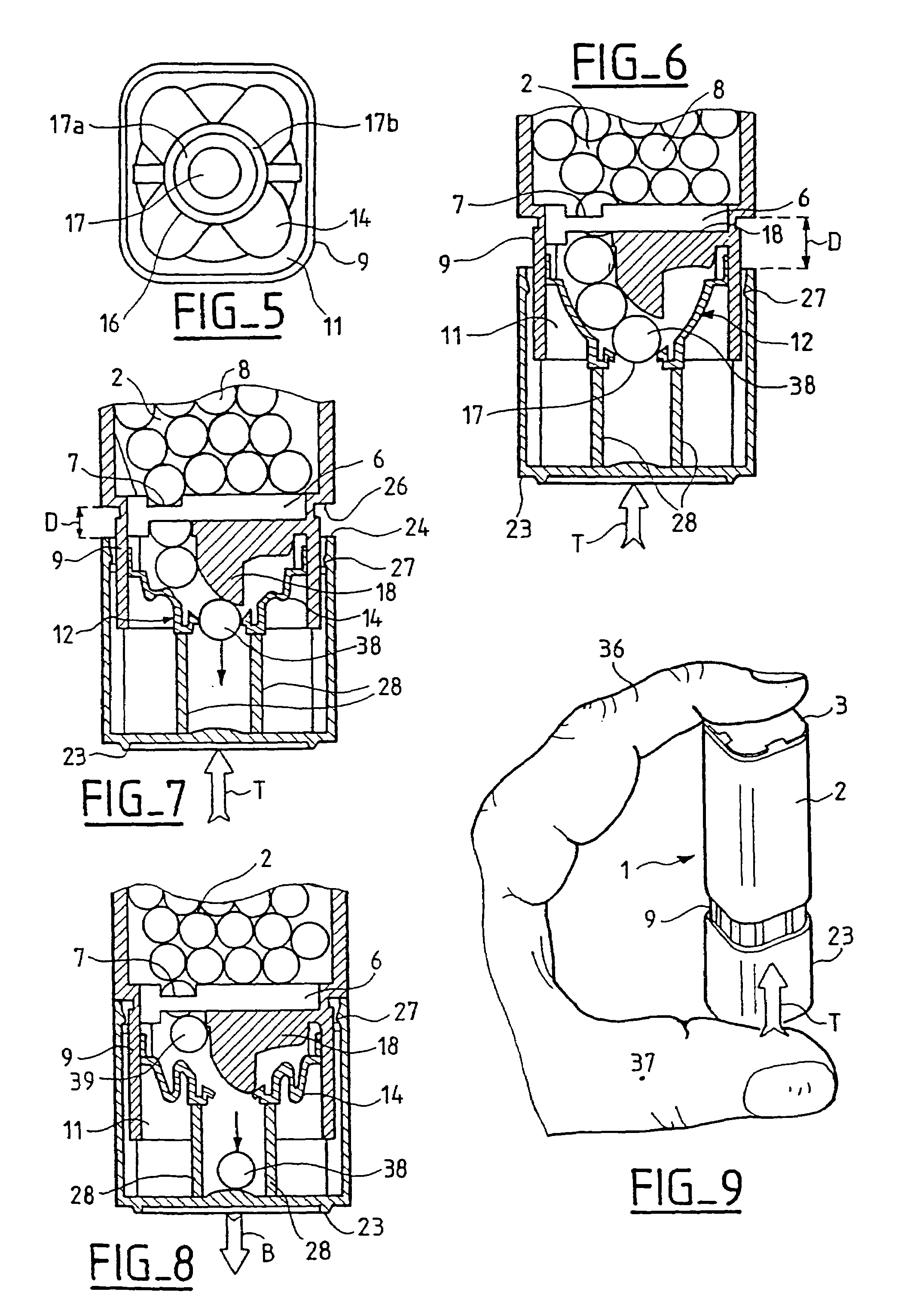

Dispenser of objects

InactiveUS7073685B1Reduce the overall heightSmall article dispensingCoin-freed apparatus detailsReciprocating motionSpring force

The invention concerns a dispenser of objects comprising a body forming a reservoir (2) for storing objects to be dispensed (8), an outlet passage (22) for said objects, arranged at one end of the body (2), and returned translation means (12) capable of performing a reciprocating movement relatively to the body (2) so as to release a predetermined number of objects (8) at each out and in stroke of the translation movement. The invention is characterized in that said returned translation movement are arranged in the form of a flexible membrane with shape memory (12) perforated with a calibrated opening (17), exerting both a spring force enabling said reciprocating movement and, by co-operation with thrust means (18), to control the dispensing of said objects.

Owner:CLARIANT PROD (FRANCE) SAS

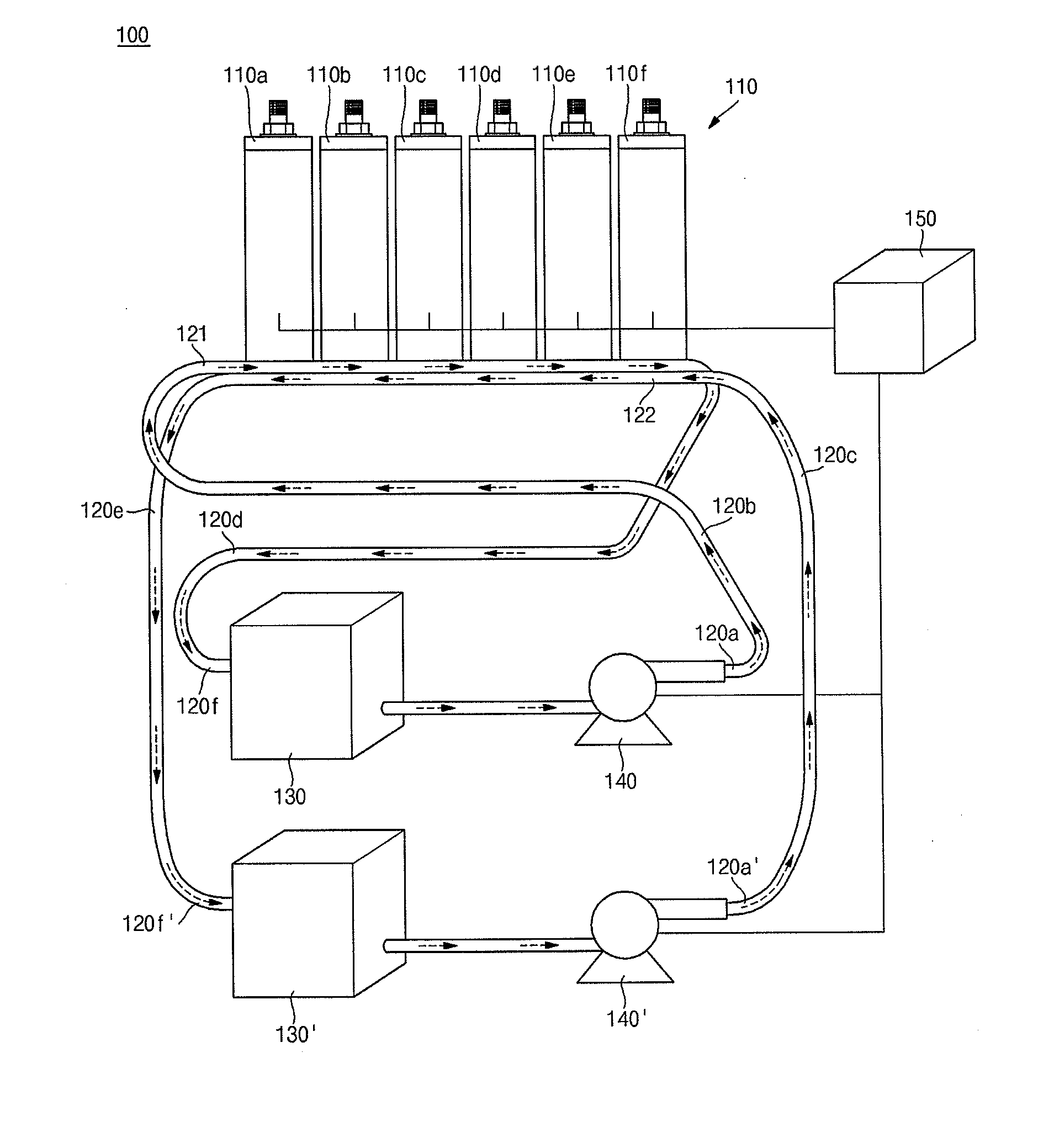

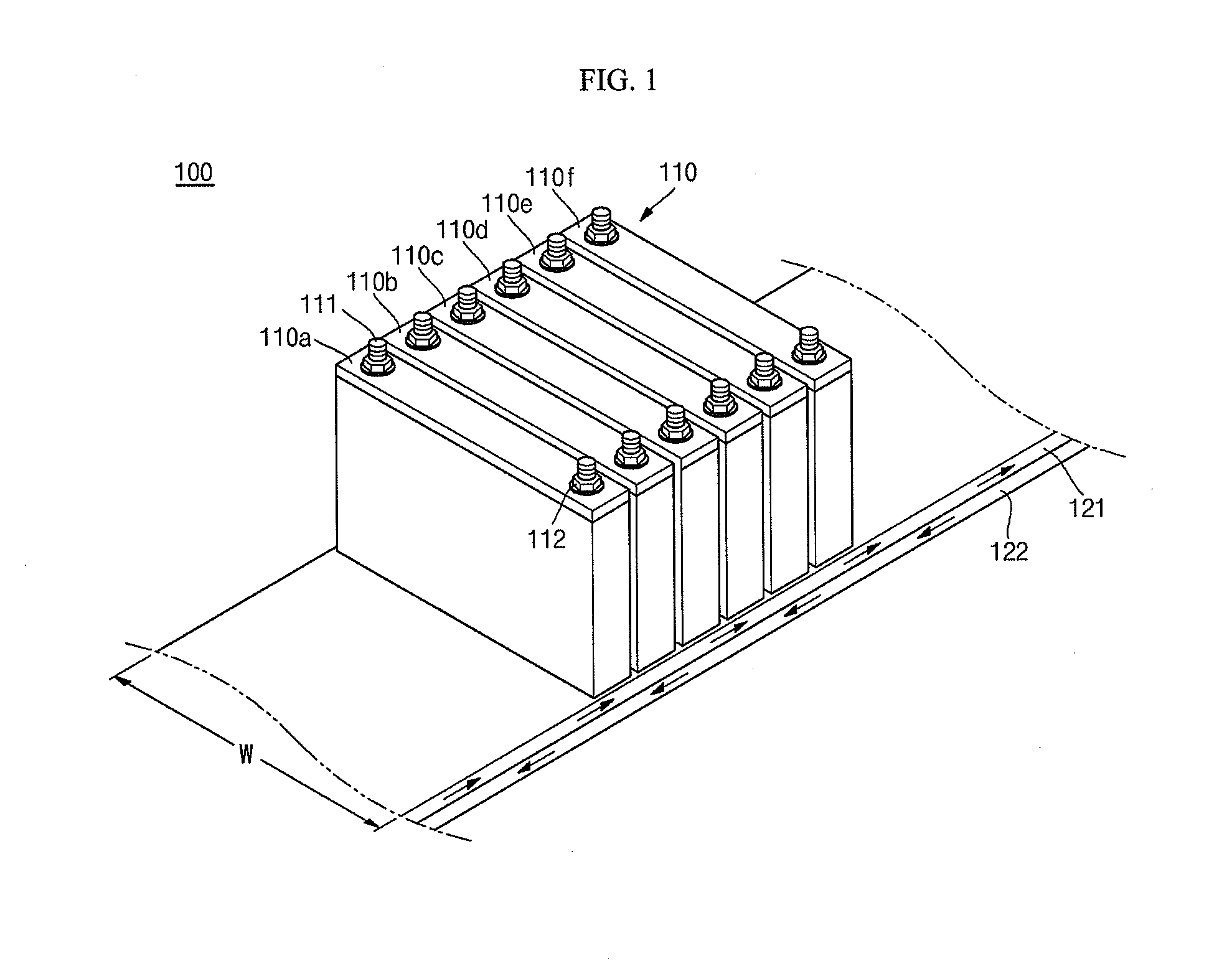

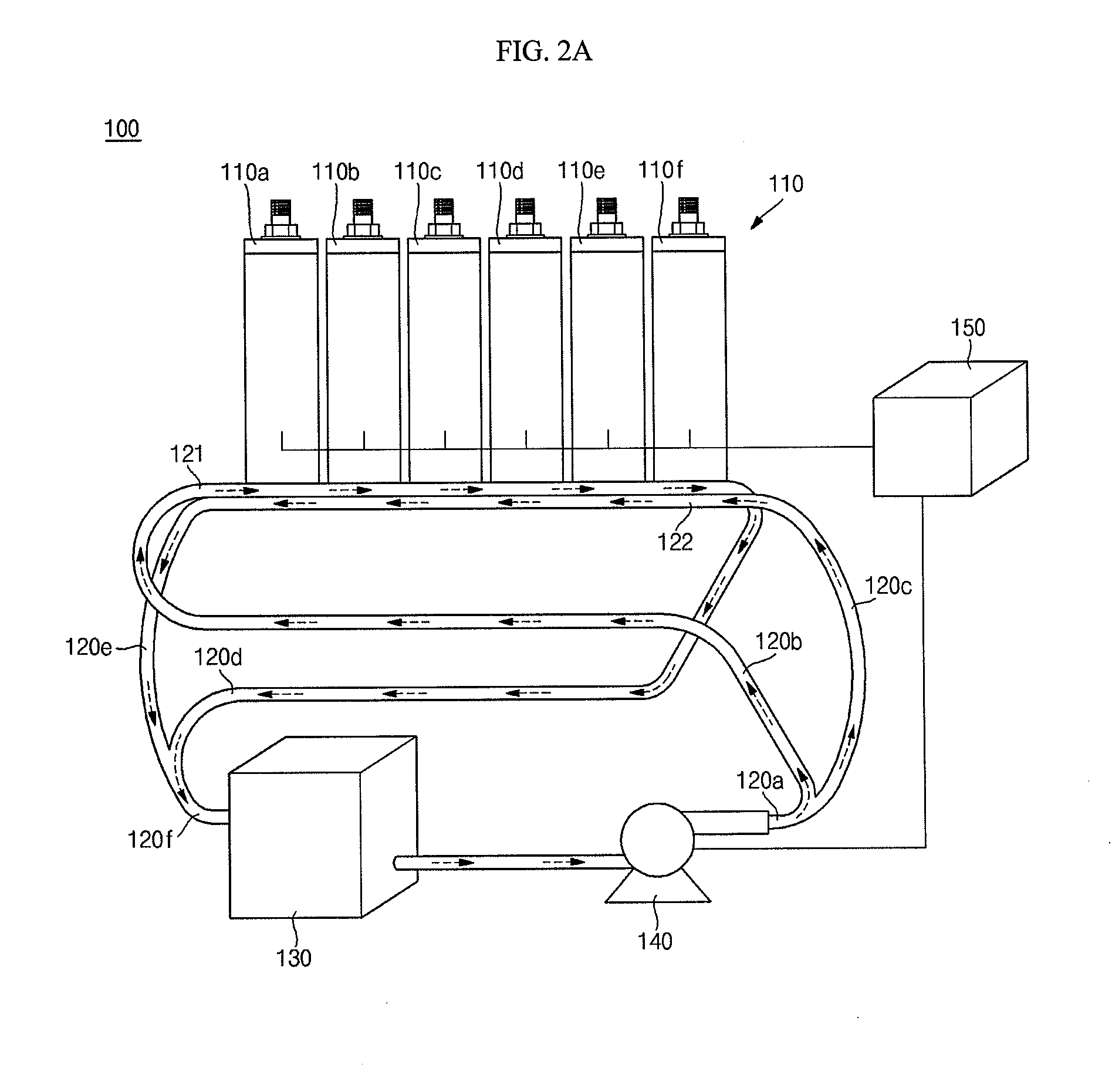

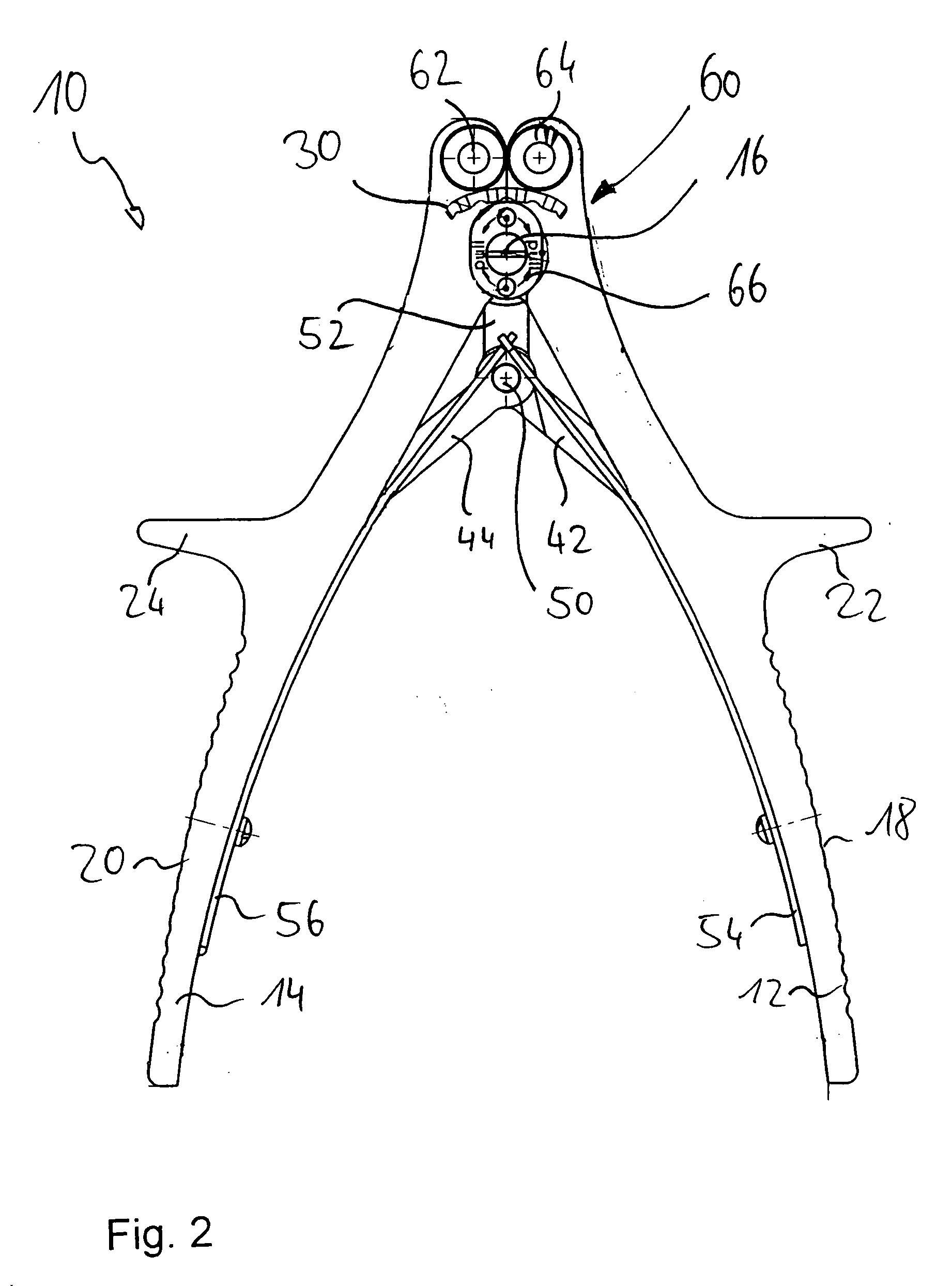

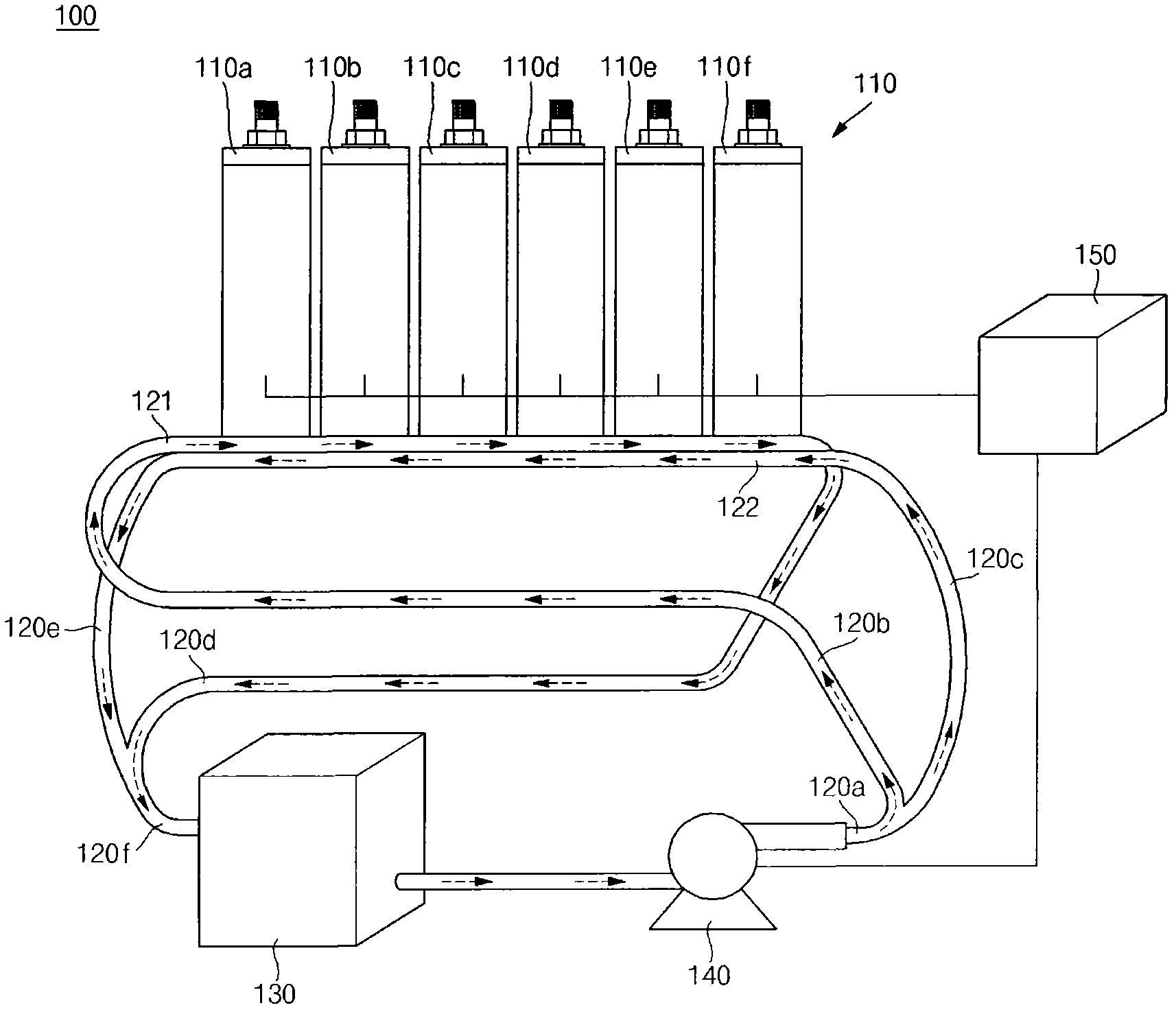

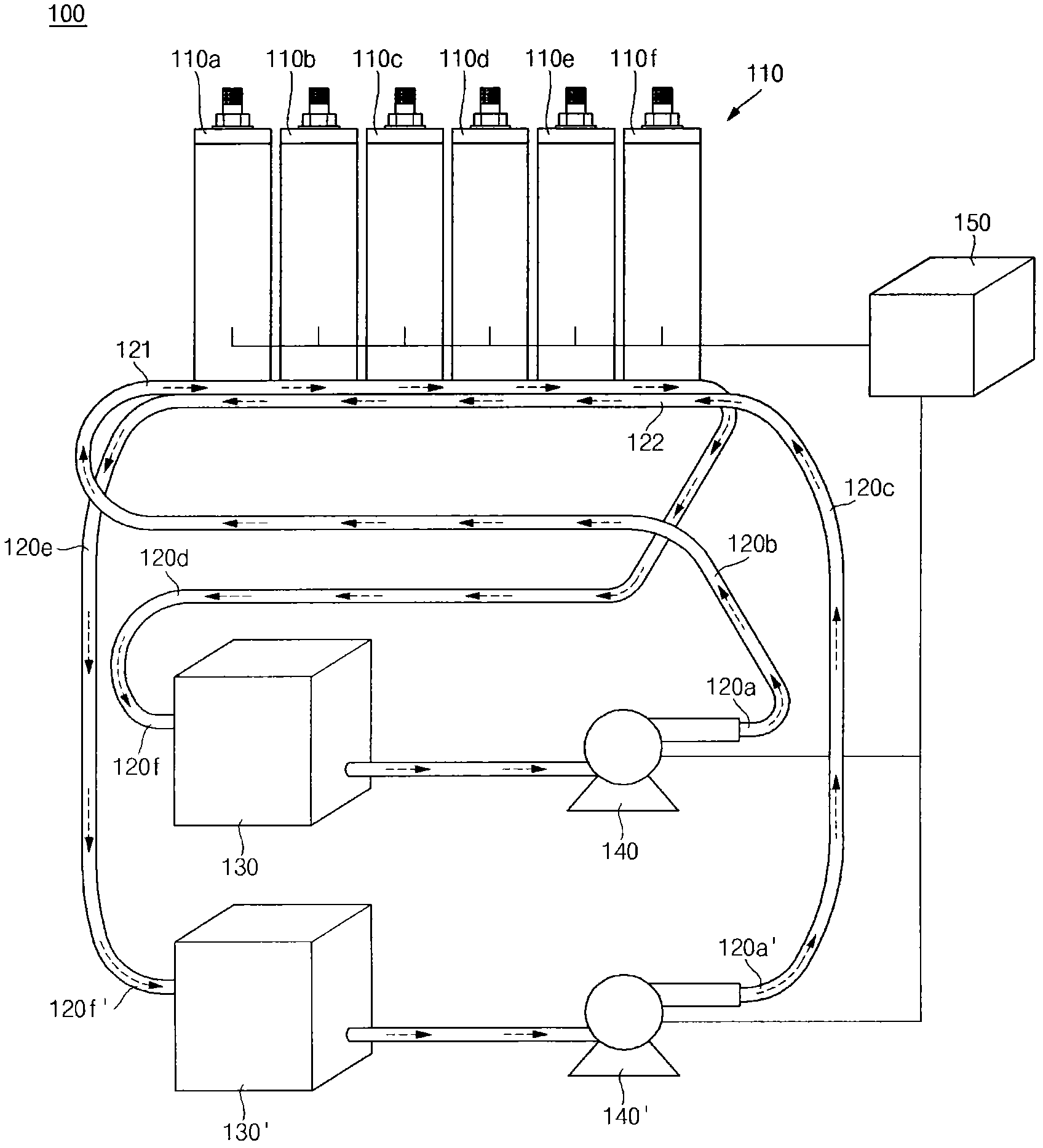

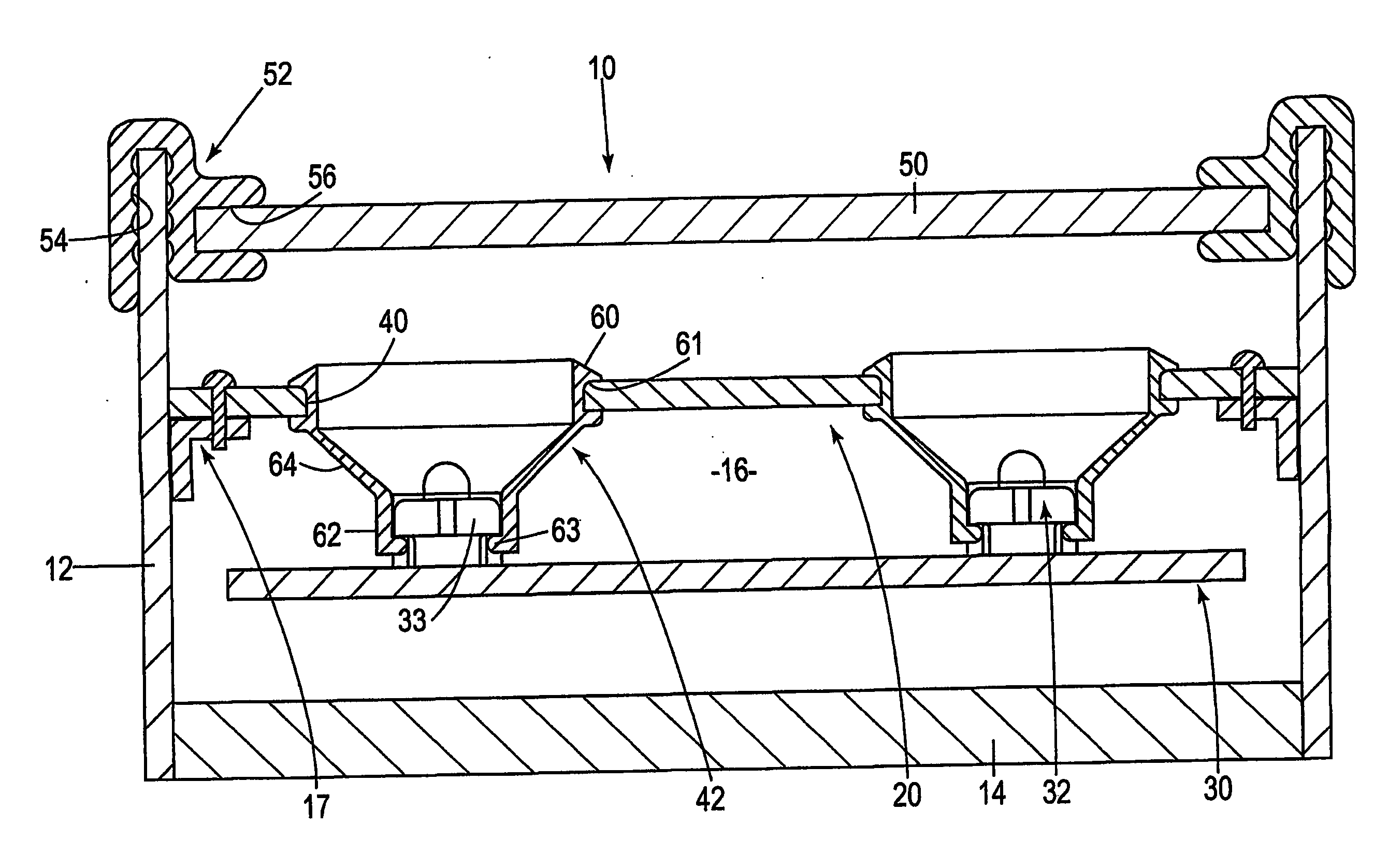

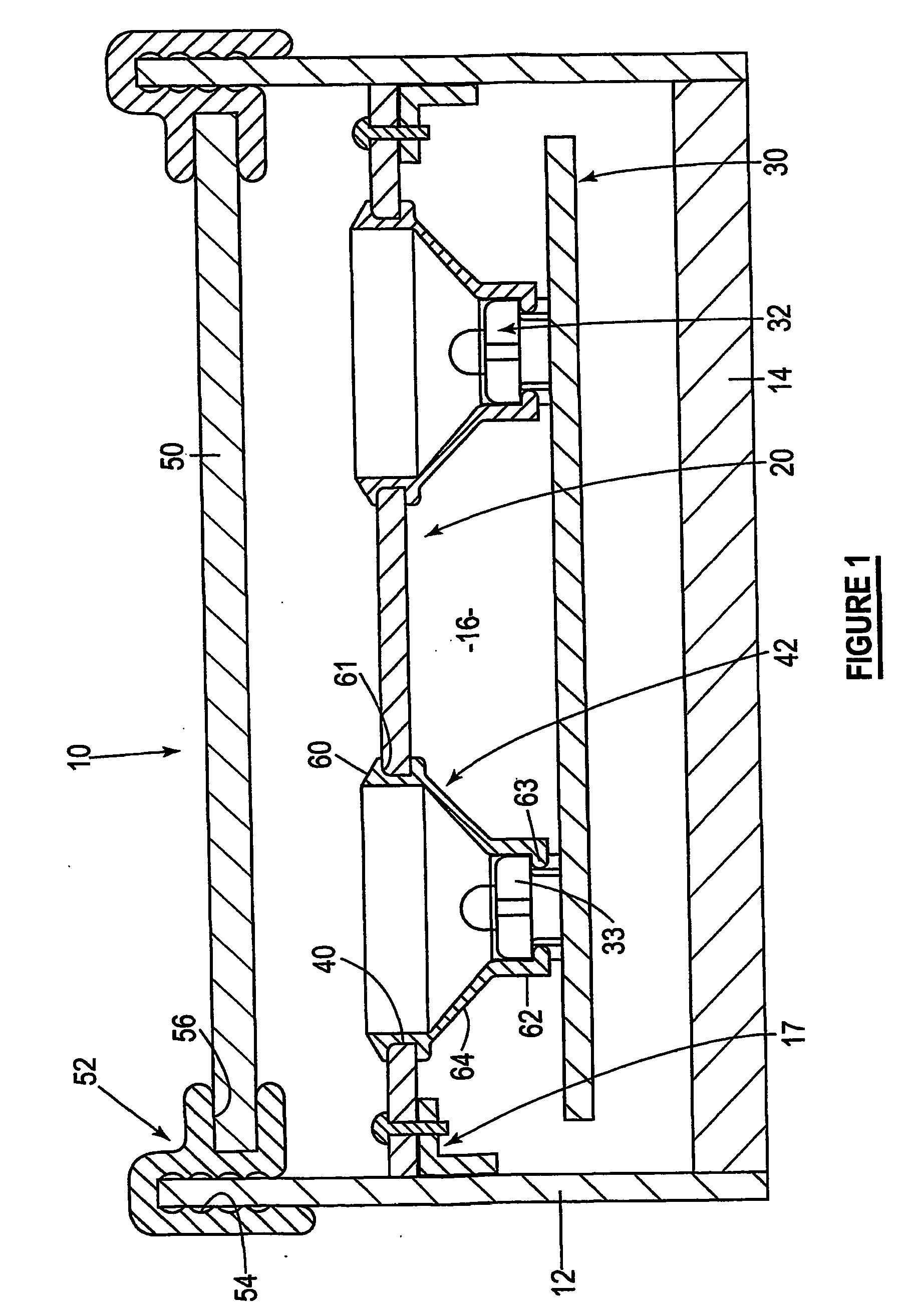

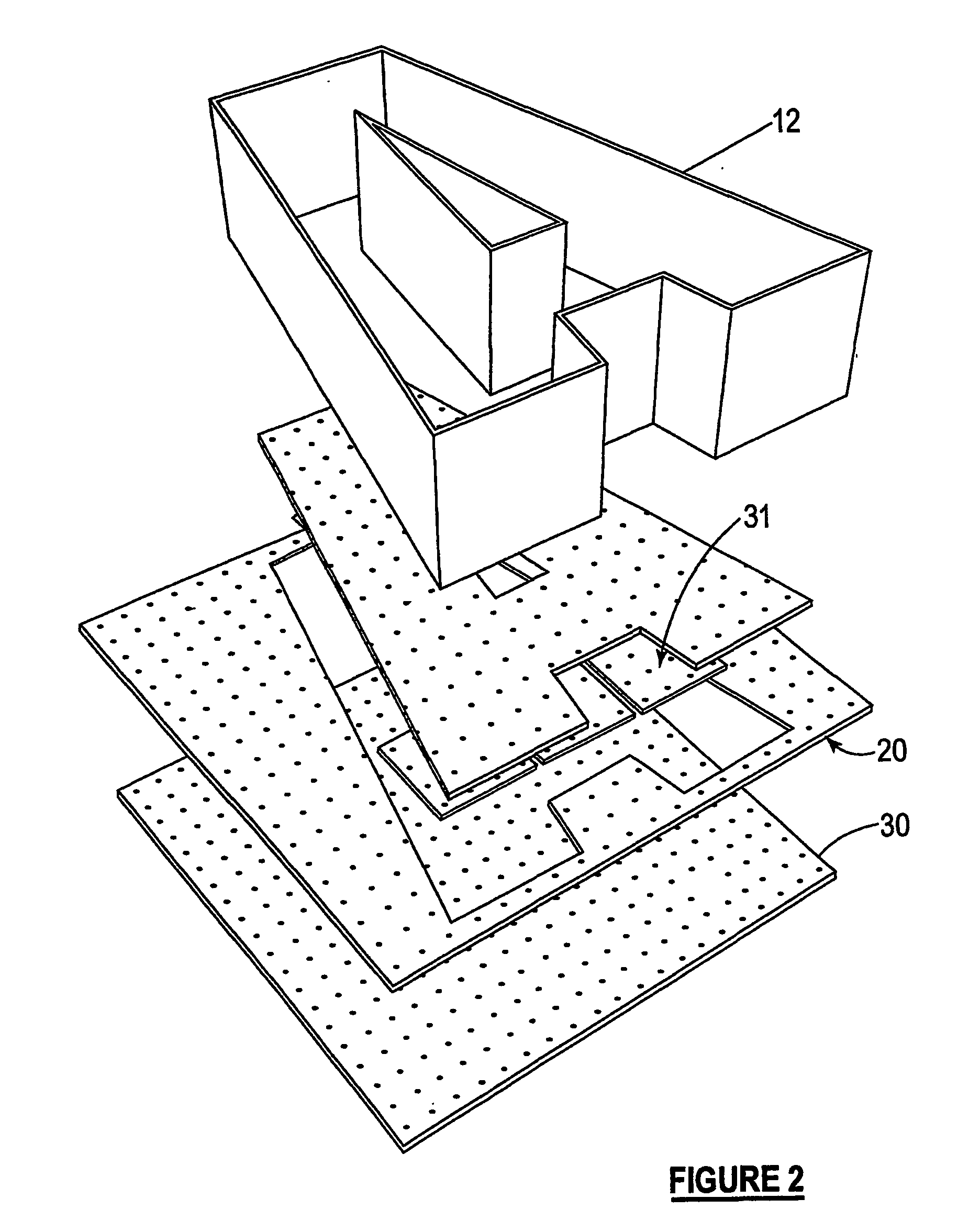

Battery pack and cooling system for a battery pack

InactiveUS20110262794A1Operation controlLighting and heating apparatusCell temperature controlEngineeringRefrigerant

A battery pack and a cooling system for a battery pack that includes a plurality of battery cells, the battery pack including a plurality of battery cells; a first refrigerant circulation pipe; and a second refrigerant circulation pipe adjacent to the first refrigerant circulation pipe, wherein the first refrigerant circulation pipe is configured to direct a refrigerant along a first circulation pathway, the second refrigerant circulation pipe is configured to direct the refrigerant along a second circulation pathway counter to the first circulation pathway, and at least one of the first refrigerant circulation pipe and the second refrigerant circulation pipe is in thermal co-operation with the battery cells.

Owner:ROBERT BOSCH GMBH +1

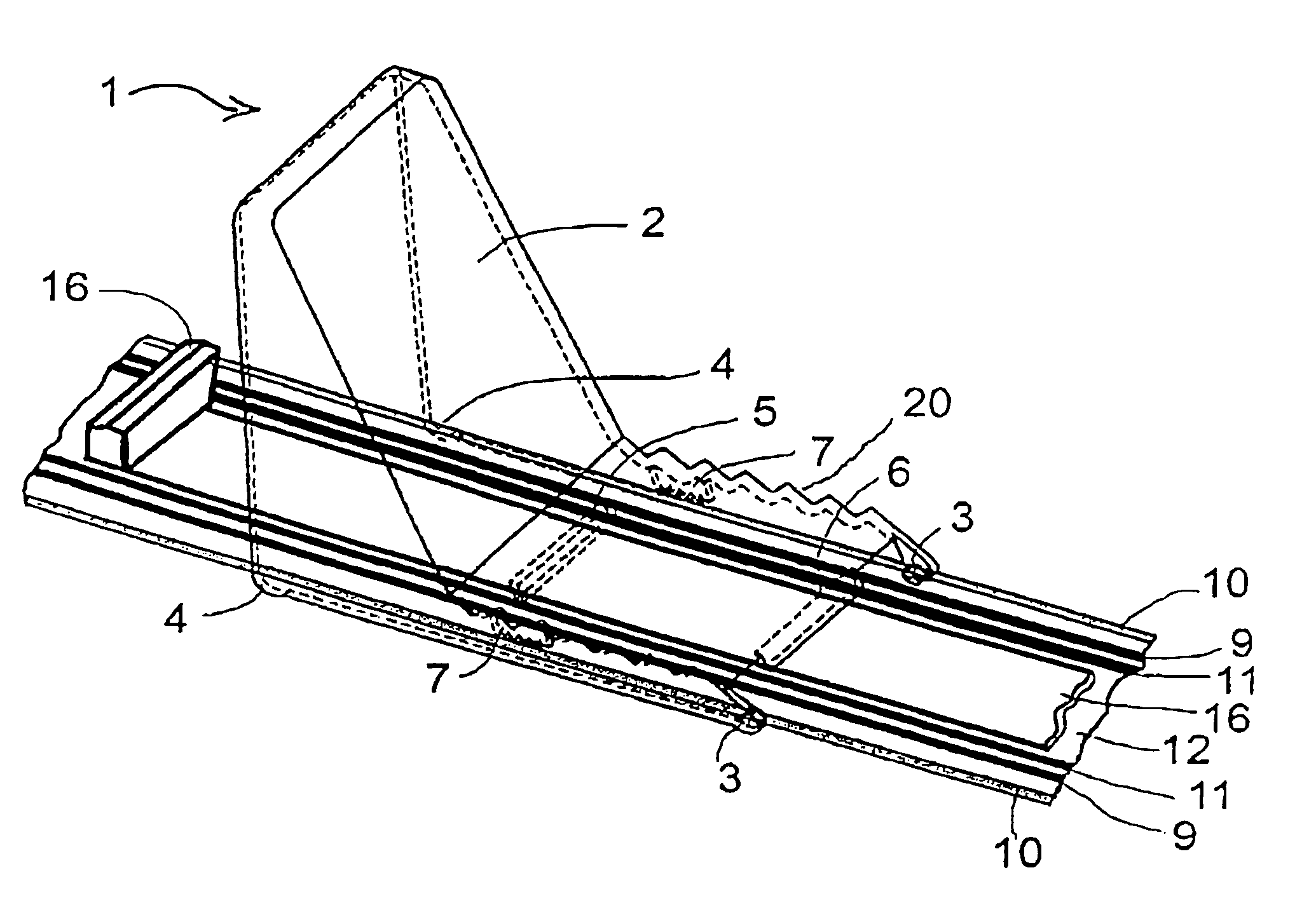

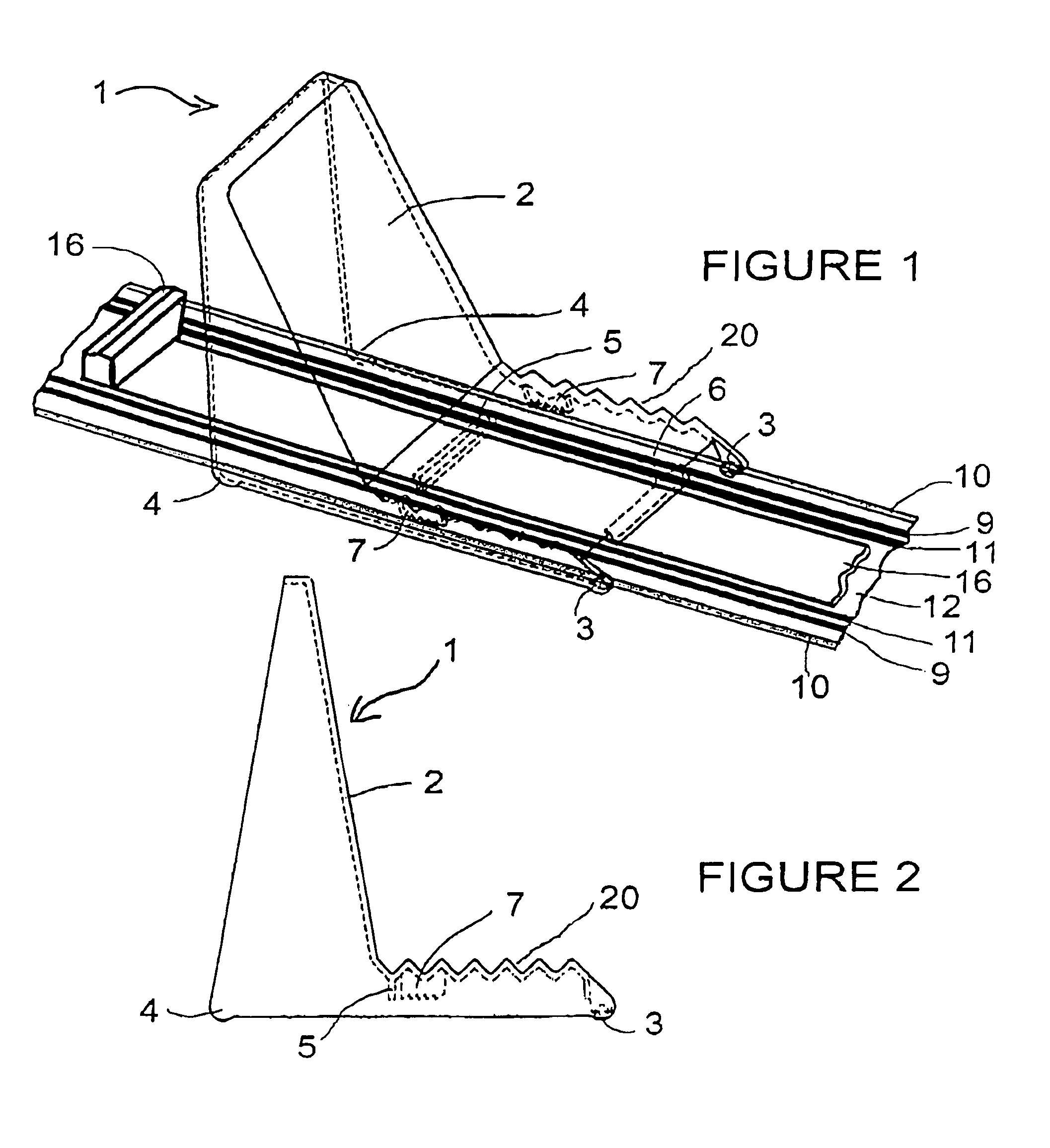

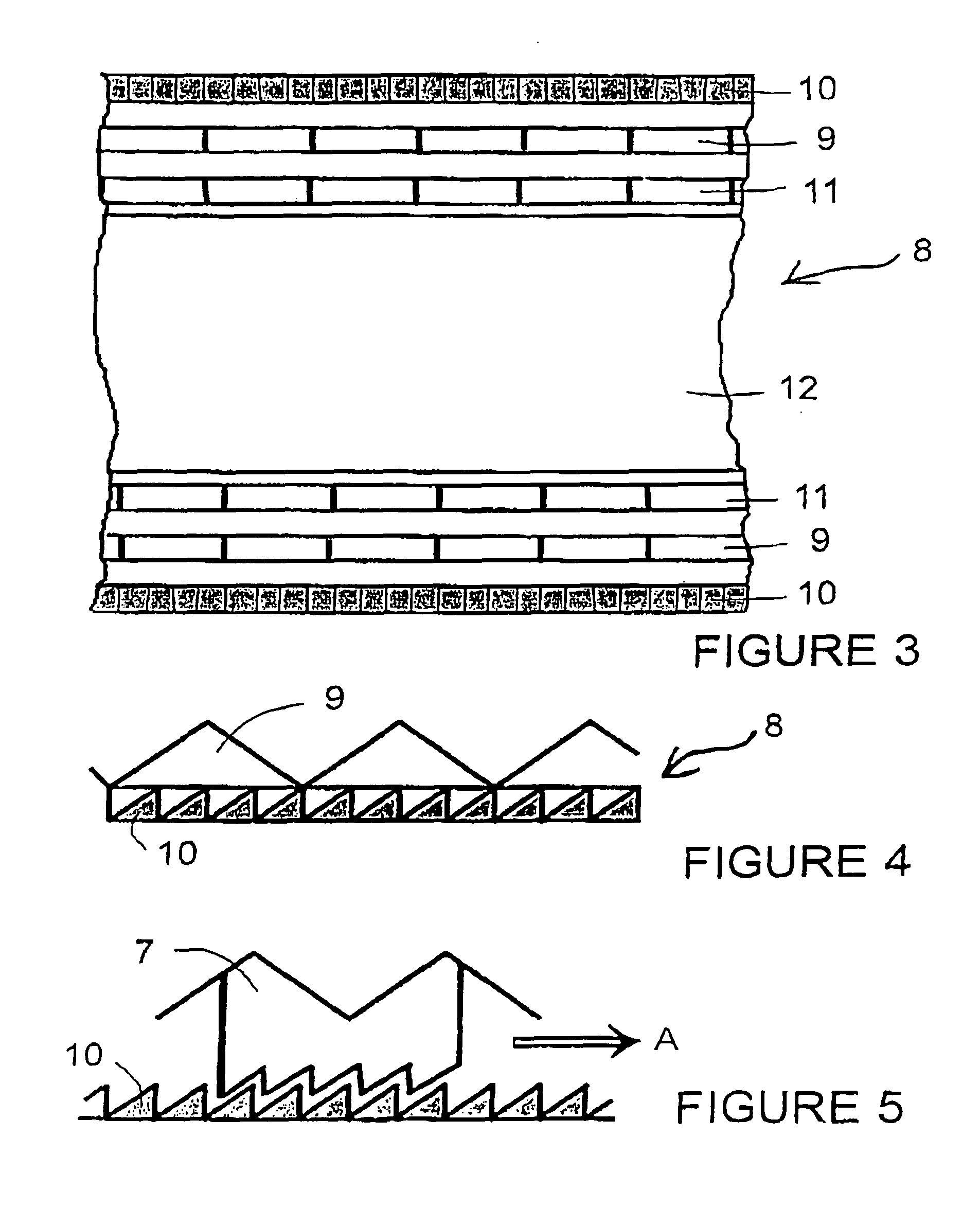

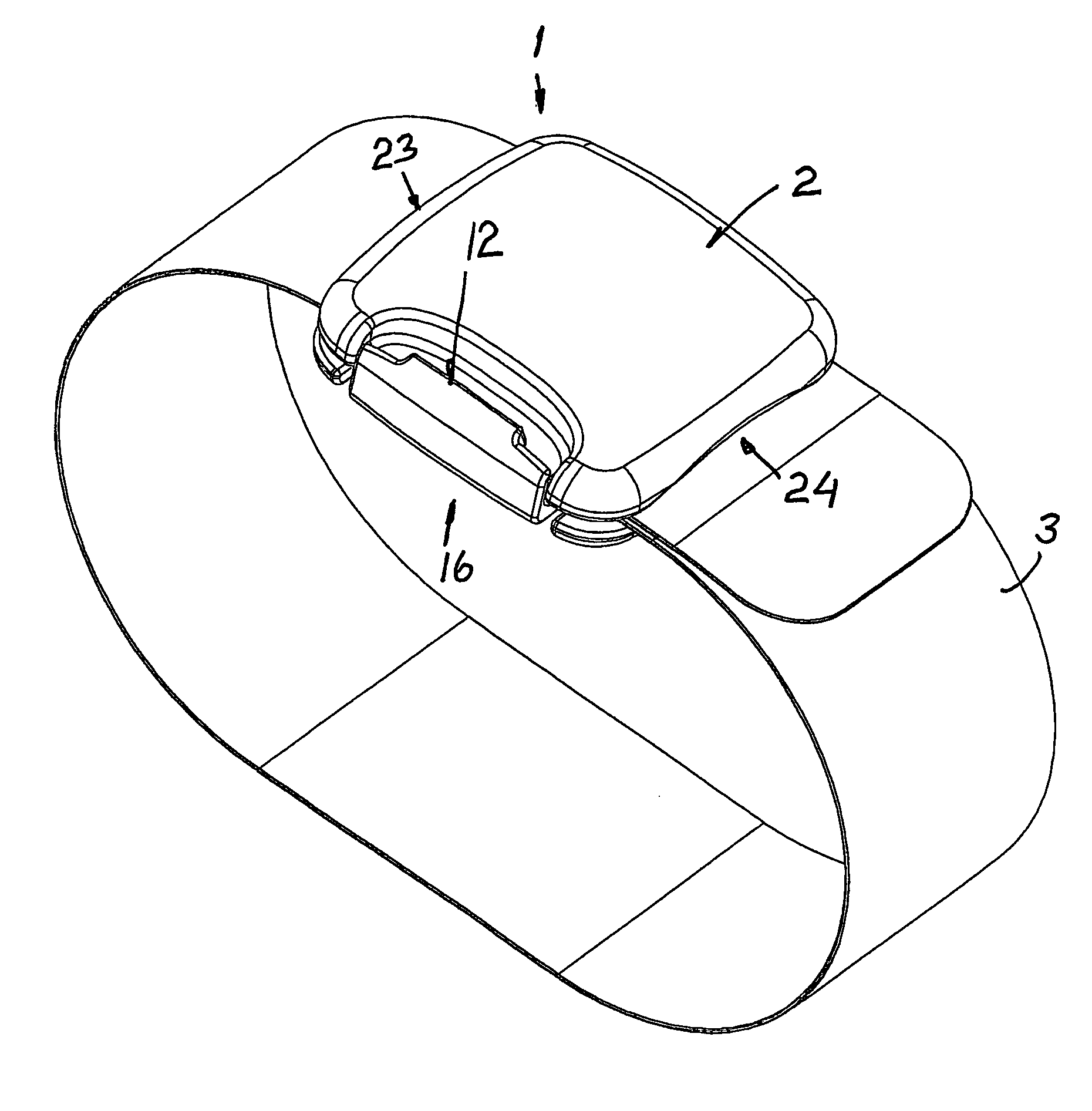

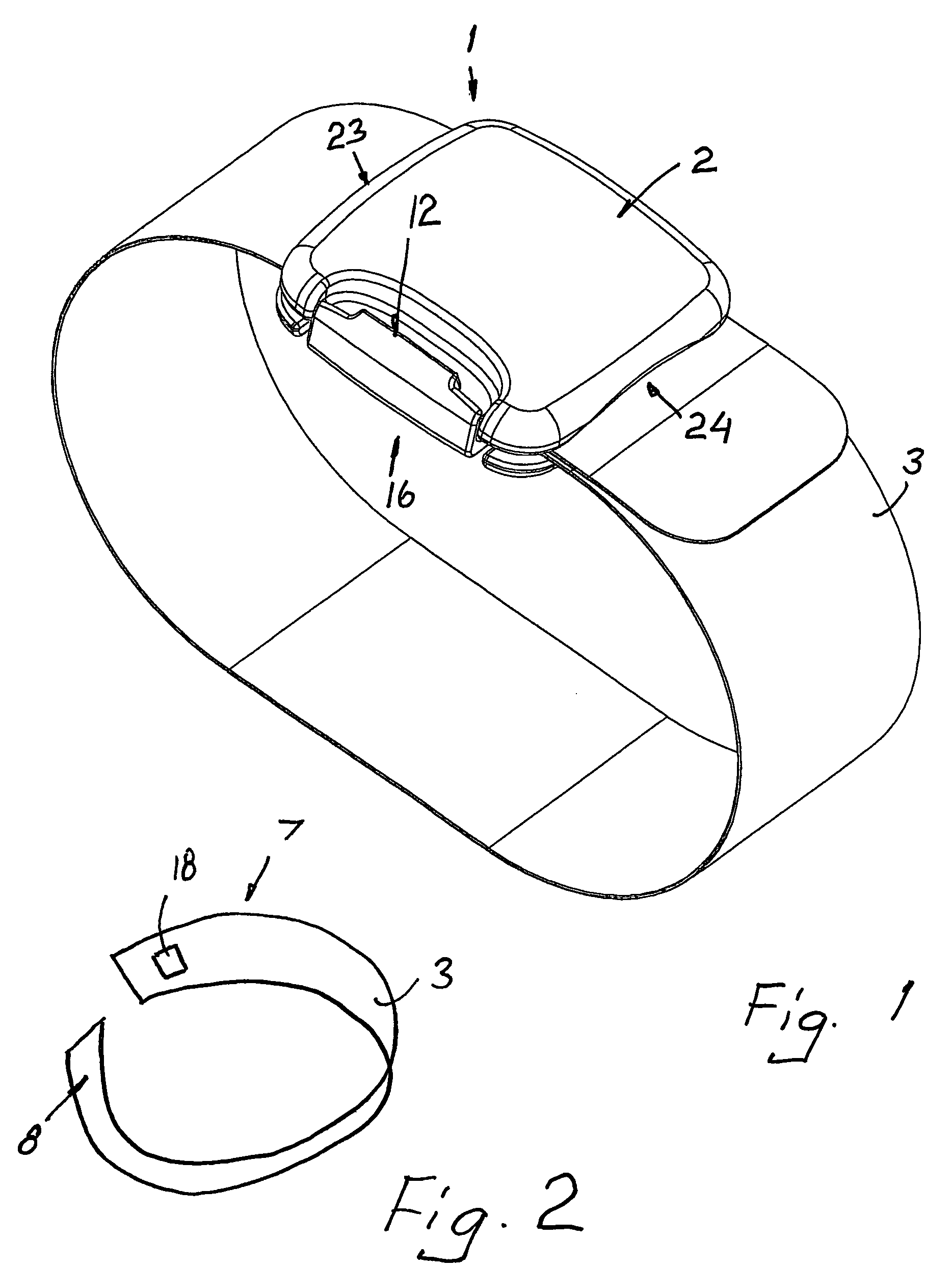

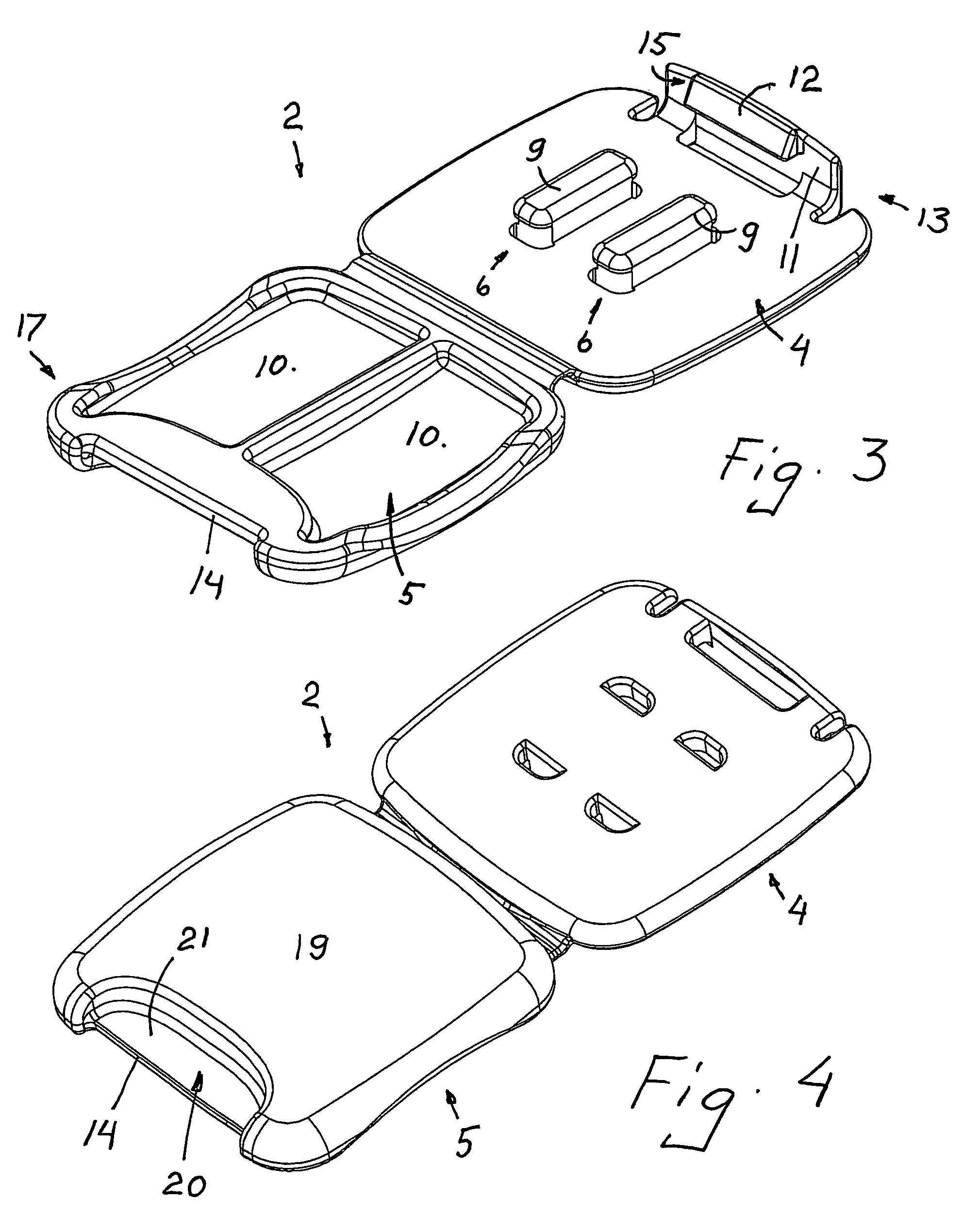

Information band

ActiveUS7406789B2Improve fastnessImprove securitySnap fastenersStampsEngineeringMechanical engineering

An information band (1) for fitting around a wrist of a wearer and for containing information about the wearer. The information band includes a clip (2) and a band (3). The clip (2) has a lid part (5) pivotably connected to a bottom part (4), at least one bulge formed between the lid and bottom parts (4, 5), and a locking device. The lid and bottom parts (4, 5) close to fix the band (3) in position around the wrist by a strong squeezing force resulting from a lockable, snappable co-operation between parts of the locking device during application of the information band so that a two-handed grip is required to open the clip and release the band.

Owner:DGINVEST

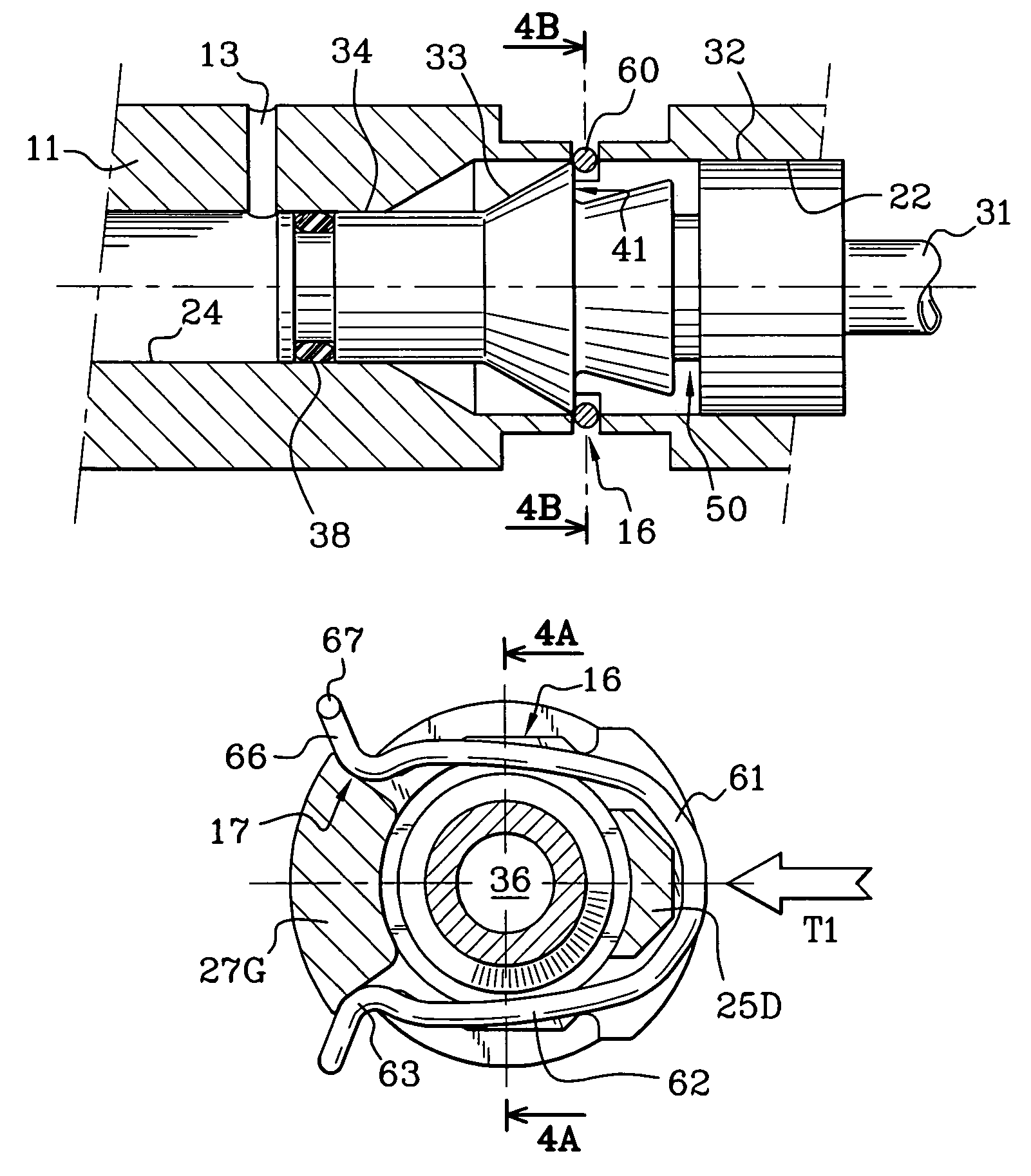

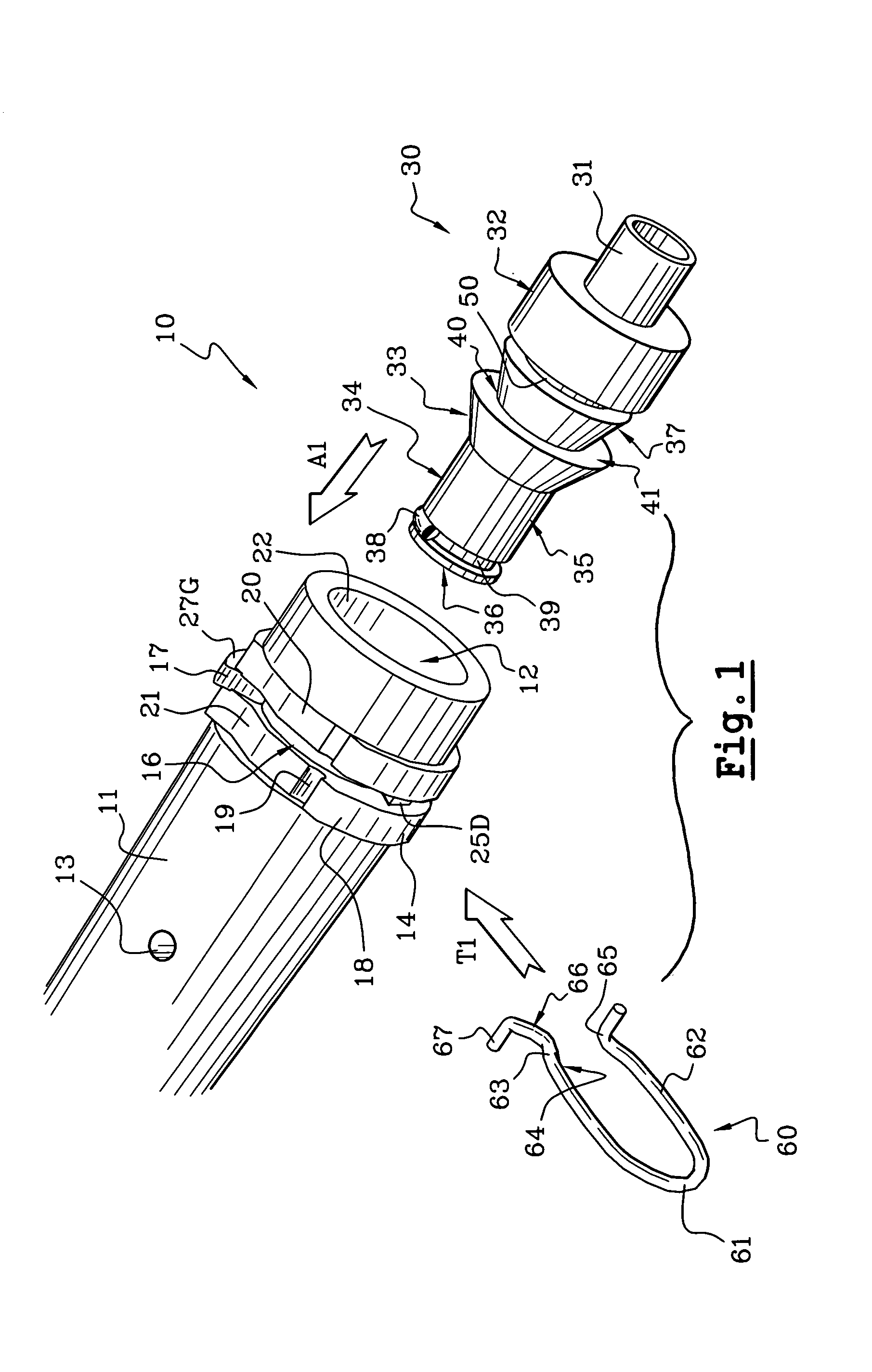

Supply connection device for a fluid pressure system

A supply connection device for a fluid pressure system, the connection includes a head designed to be axially received in a body of a supply intake, and the connection is capable of being locked in a front position axially engaged in the supply intake body by a locking mechanism, which includes a globally symmetrical U-shaped pin with two transverse locking branches. The connection is unlocked from the body, for axially releasing, at least partly, rearward the connection outside the body, by elastic deformation of the locking mechanism which results from the co-operation between at least a part of the locking branches and at least a part of the body under the action of a releasing force exerted on the locking mechanism along a transverse direction. The elastic deformation is obtained by exerting a releasing force thrusting a connecting section of the two braches of the pin.

Owner:VALEO EMBRAYAGES SAS

Method, and a device for converting speech by replacing inarticulate portions of the speech before the conversion

InactiveUS9123343B2Increase flexibilityEasy loadingSpeech recognitionSpeech identificationMobile device

An arrangement for converting speech into text comprises a mobile device (202) and a server entity (208) configured to perform the conversion and additional optional processes in co-operation. The user of the mobile device (202) may locally edit the speech signal prior to or between the execution of the actual speech recognition tasks, by replacing an inarticulate portion of the speech signal with a new version being recording of the portion. Task sharing details can be negotiated dynamically based on a number of parameters.

Owner:DICTA DIRECT LLC

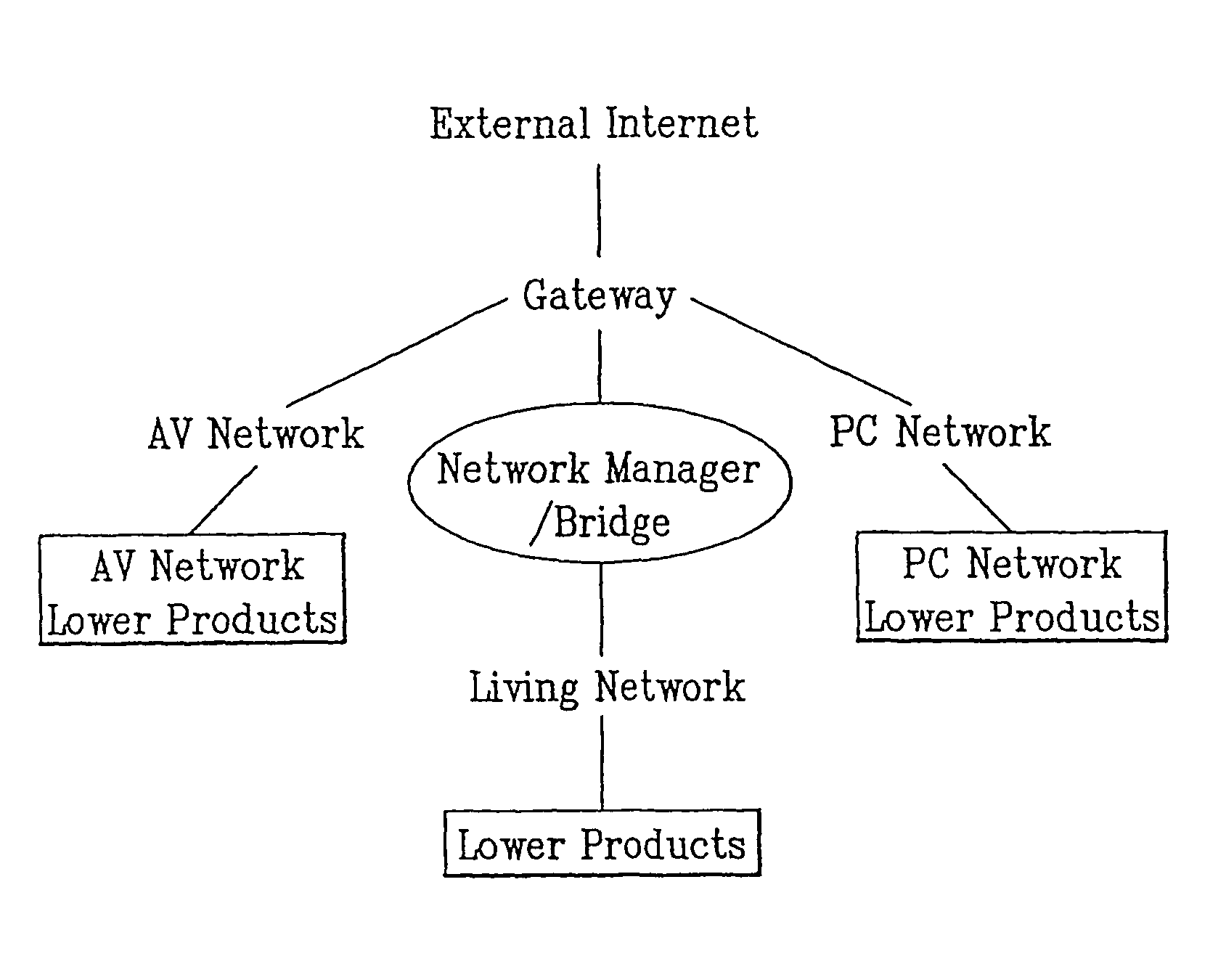

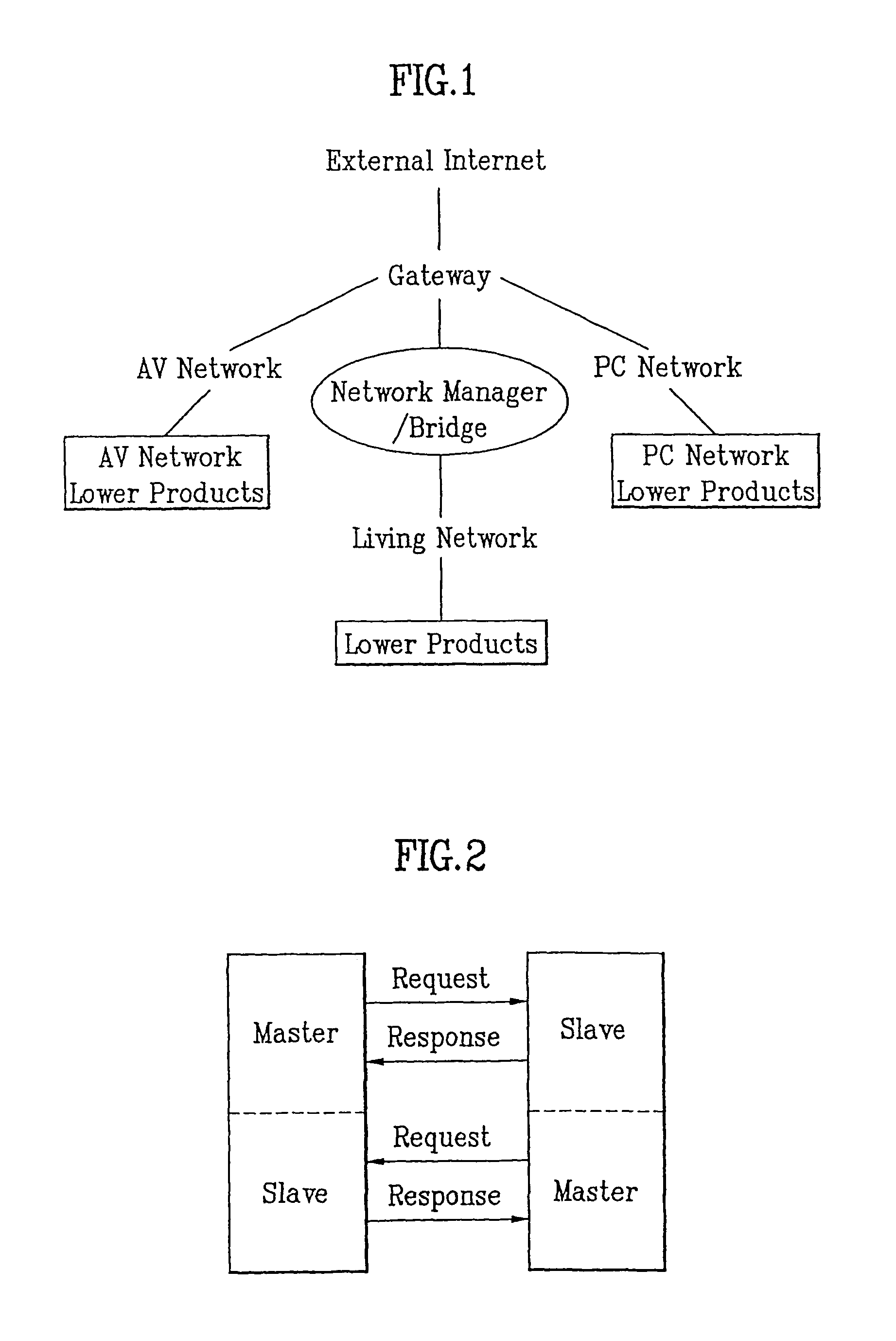

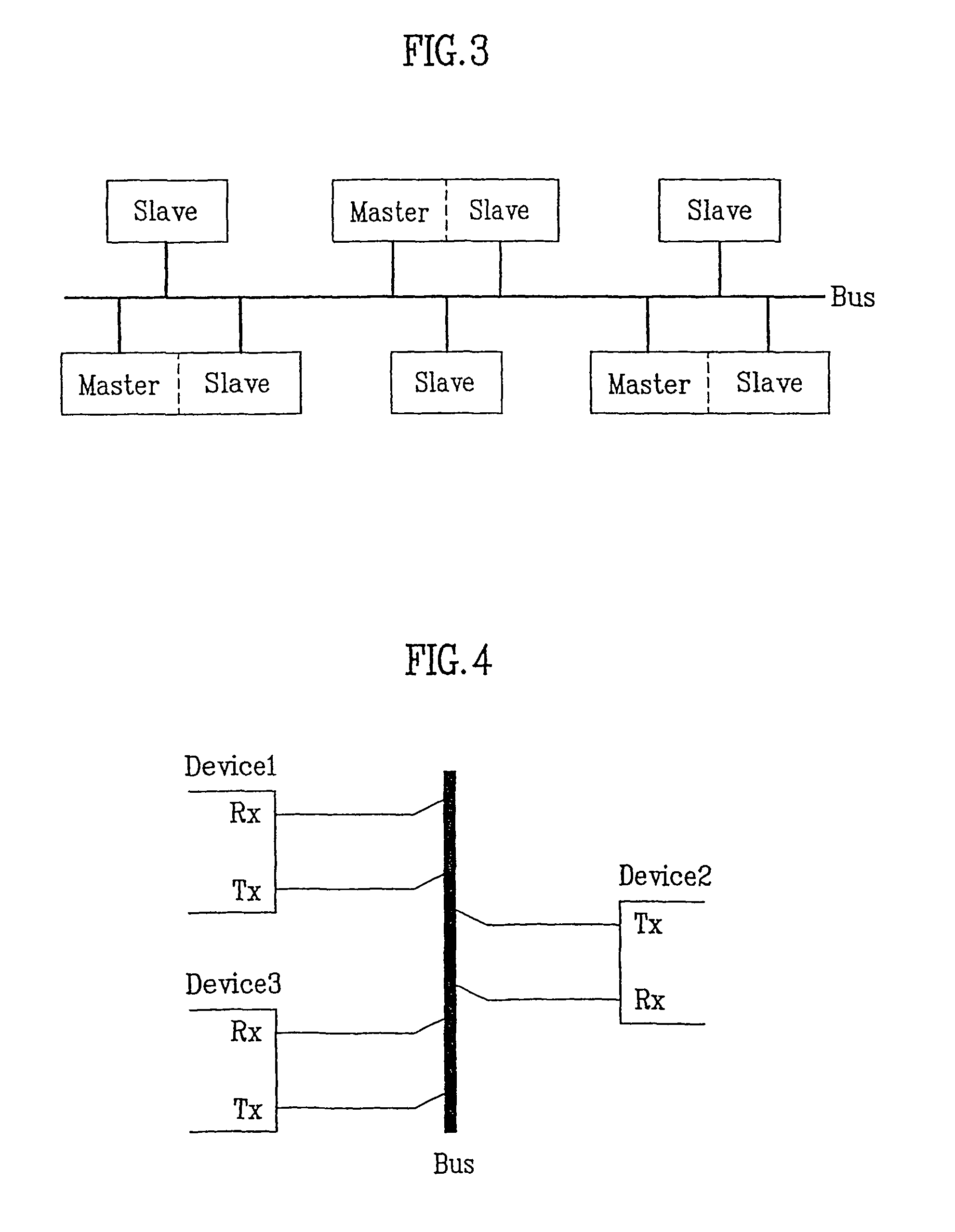

Network control system for home appliances

InactiveUS7873699B2Special service provision for substationPulse modulation television signal transmissionMicrocomputerControl system

Disclosed is a network control system for home appliances that satisfies the characteristics of low-cost and high-efficiency with respect to currently used appliances adopting a low-performance microcomputer. The system is constructed to define a master / slave type communication structure with respect to the respective appliances; construct a network by connecting the appliances through the serial communication function; and enable the appliances to communicate with one another if a predetermined communication event is produced. According to the system, an optimized network for the home appliances can be implemented, and operation states of the respective appliances can be displayed through the co-operation among the appliances, thereby maximizing the user convenience.

Owner:LG ELECTRONICS INC

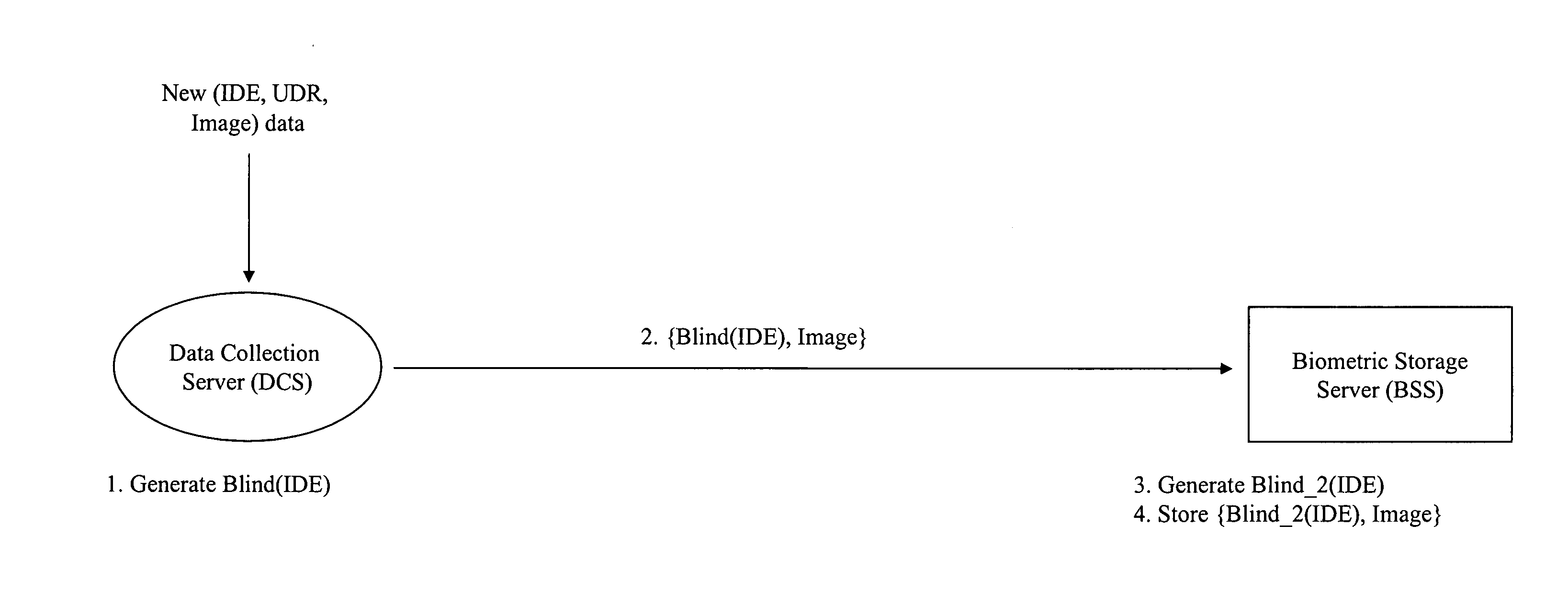

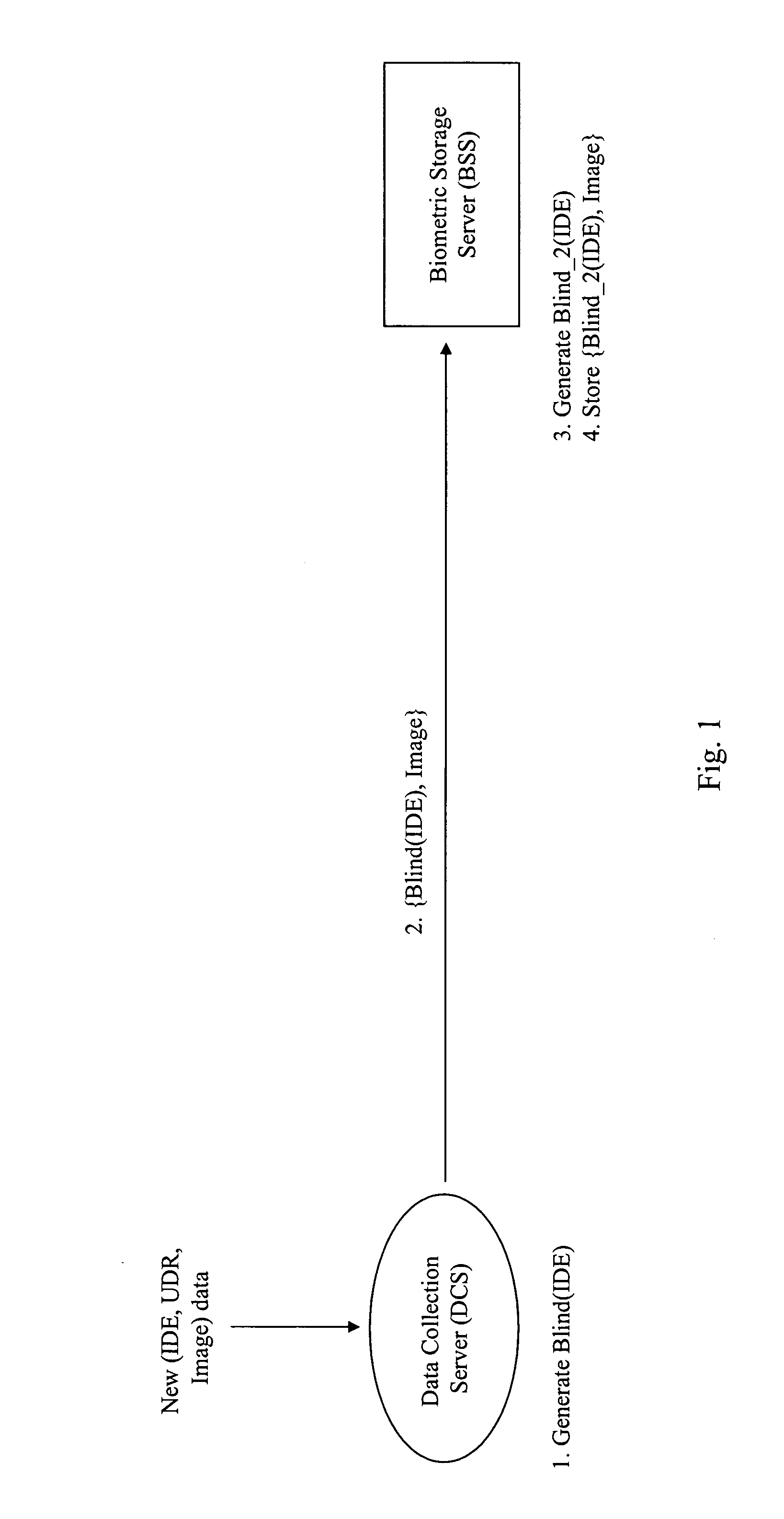

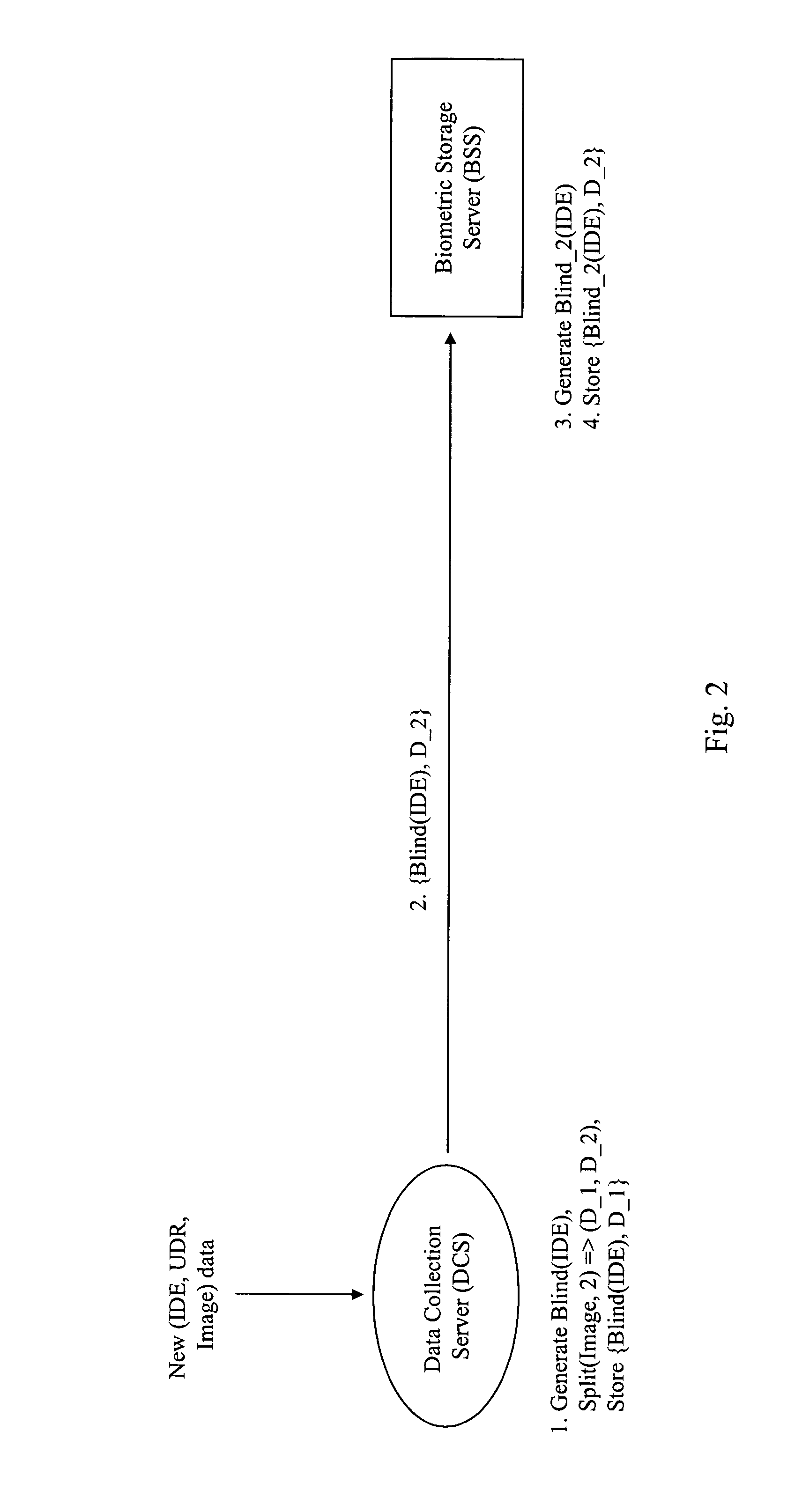

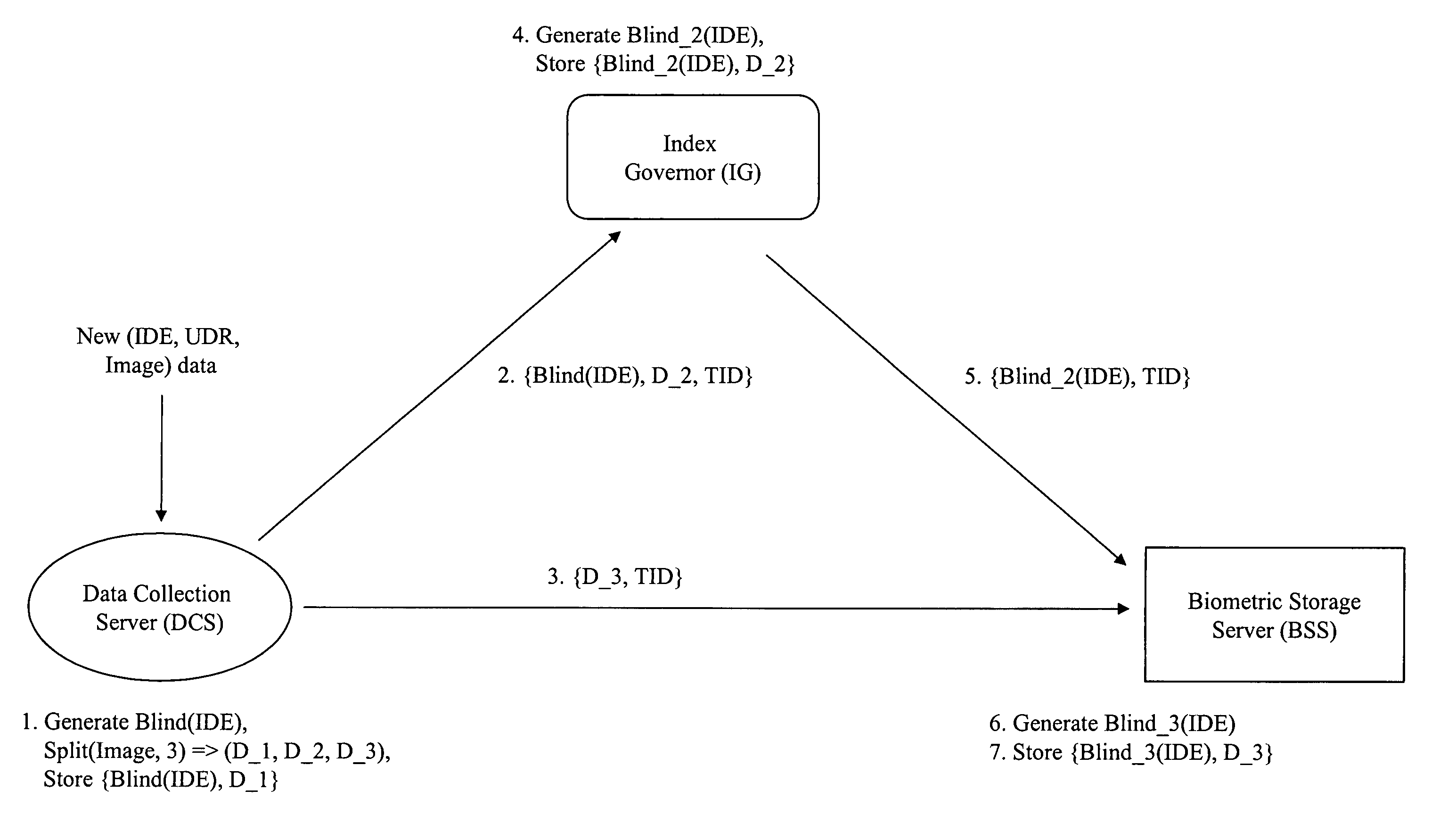

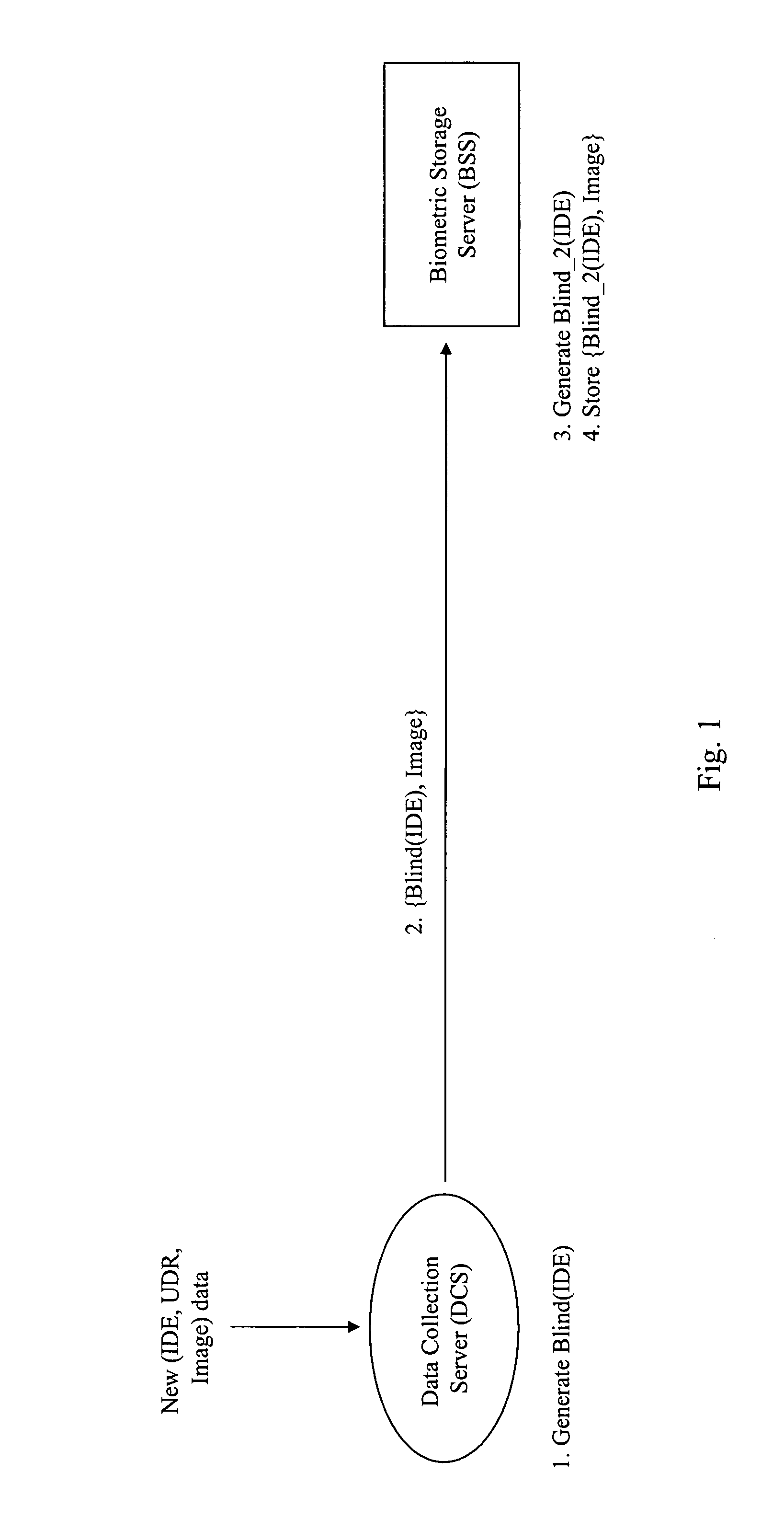

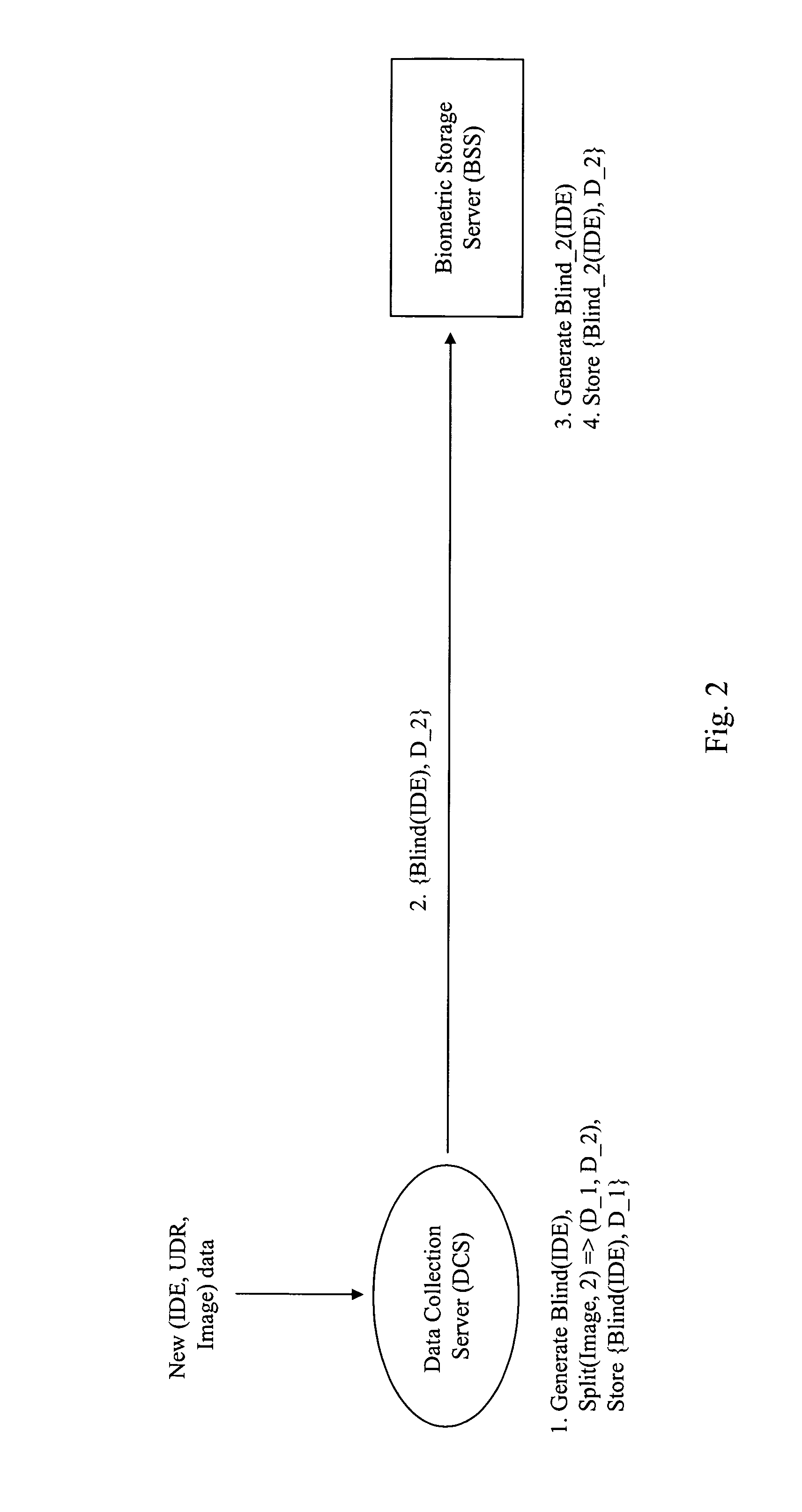

System and method for protecting the privacy and security of stored biometric data

ActiveUS20060239511A1Privacy protectionEnsure safetyElectric signal transmission systemsImage analysisBiometric dataInternet privacy

A data storage system that protects privacy and ensures security includes a plurality of nodes in a networked architecture, the nodes being adapted to securely communicate and co-operate with one another to allow storage and retrieval of data. A single piece of biometric data is associated only with a blinded identifier and securely divided across one or more nodes, adapted for data storage. The data itself and the link to the original individual, from whom the biometric was acquired, cannot be obtained without the co-operation of two or more nodes.

Owner:DAON TECH

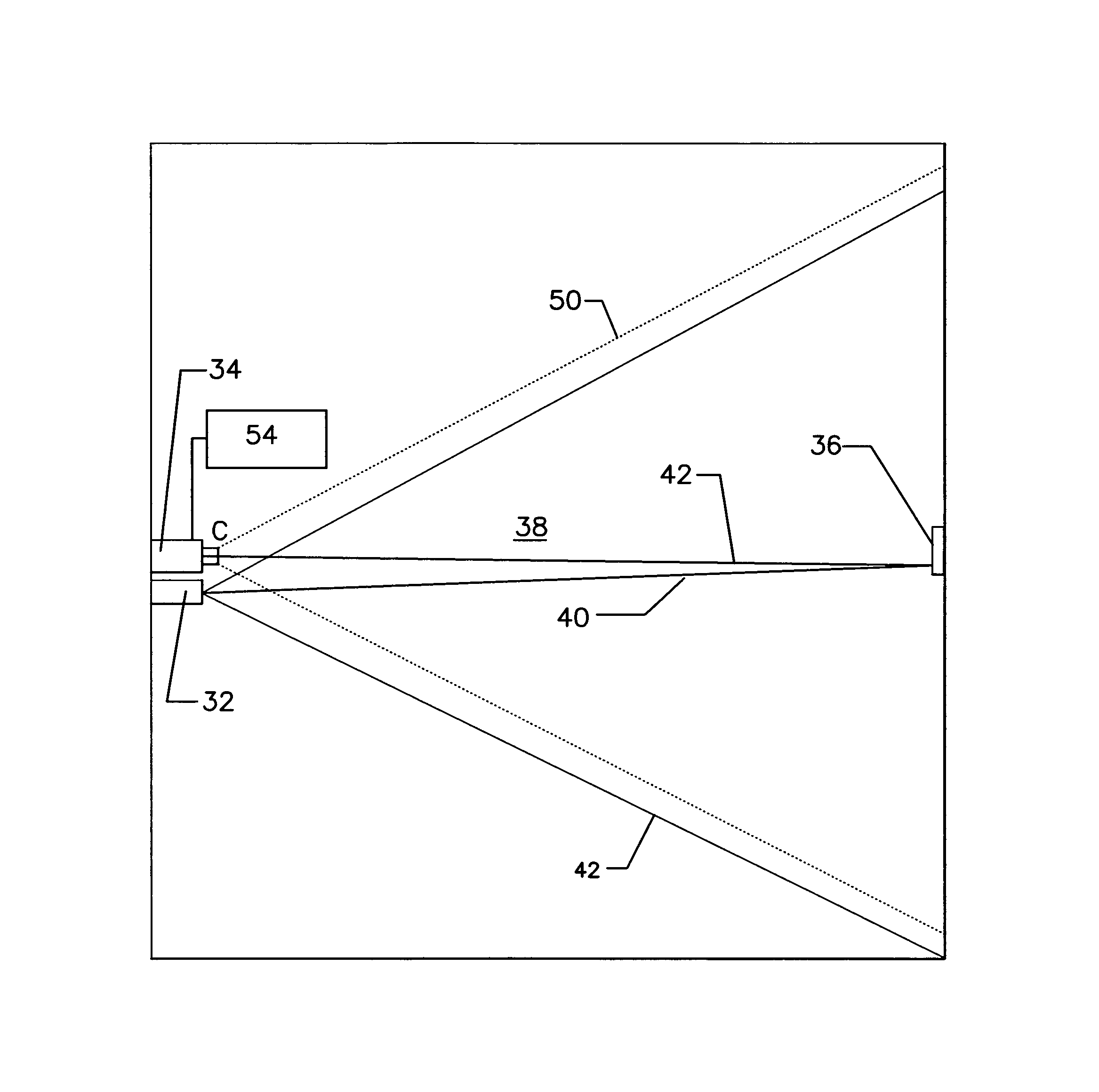

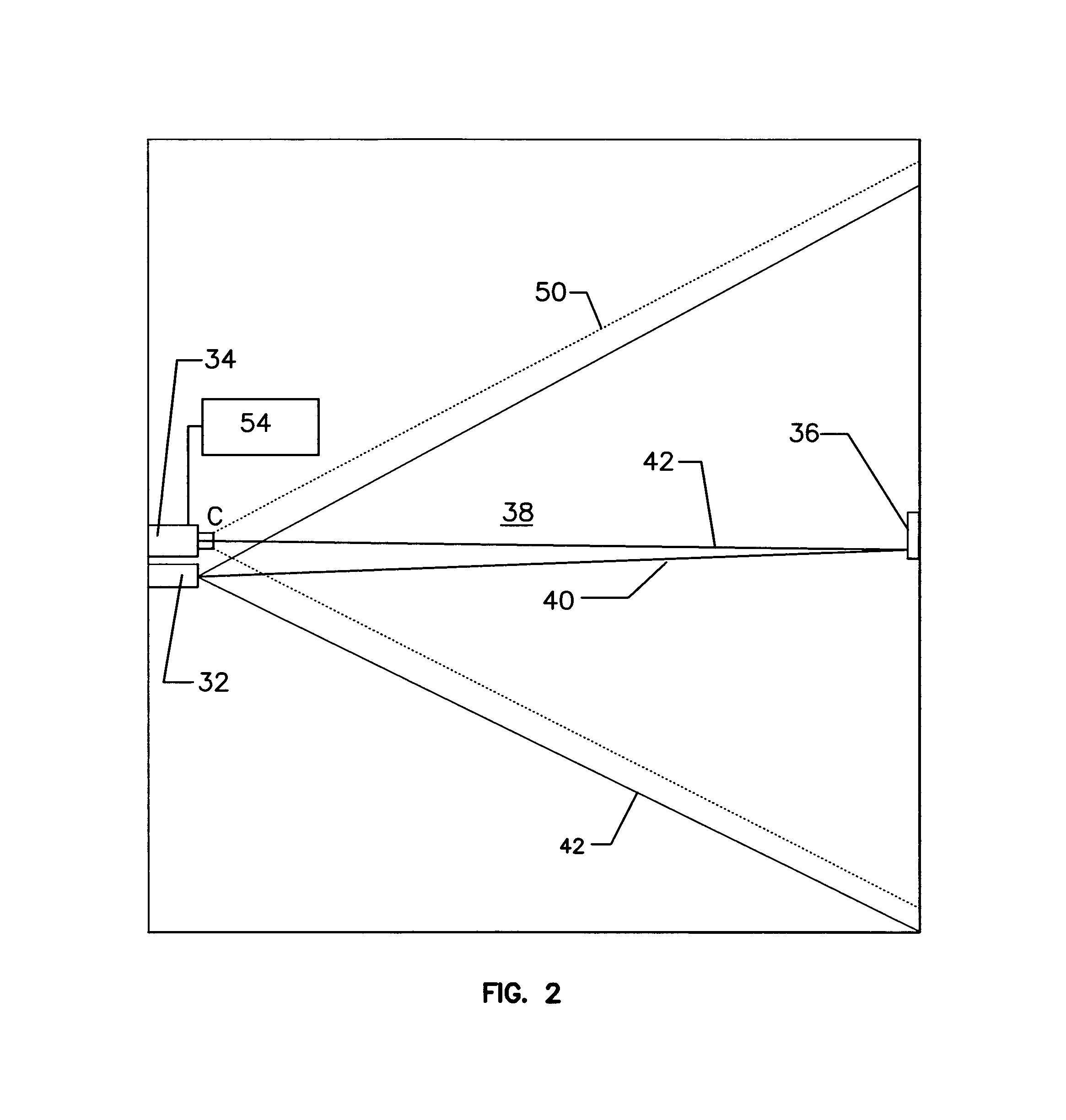

Particle detectors

ActiveUS8797531B2Sensitive to lightTransistorScattering properties measurementsLight beamField of view

A beam detector (10) including a light source (32), a receiver (34), and a target (36), acting in co-operation to detect particles in a monitored area (38). The target (36), reflects incident light (40), resulting in reflected light (32) being returned to receiver (34). The receiver (34) is a receiver is capable of recording and reporting light intensity at a plurality of points across its field of view. In the preferred form the detector (10) emits a first light beam (3614) in a first wavelength band; a second light beam (3618) in a second wavelength band; and a third light beam (3616) in a third wavelength band, wherein the first and second wavelengths bands are substantially equal and are different to the third wavelength band.

Owner:GARRETT THERMAL SYST LTD

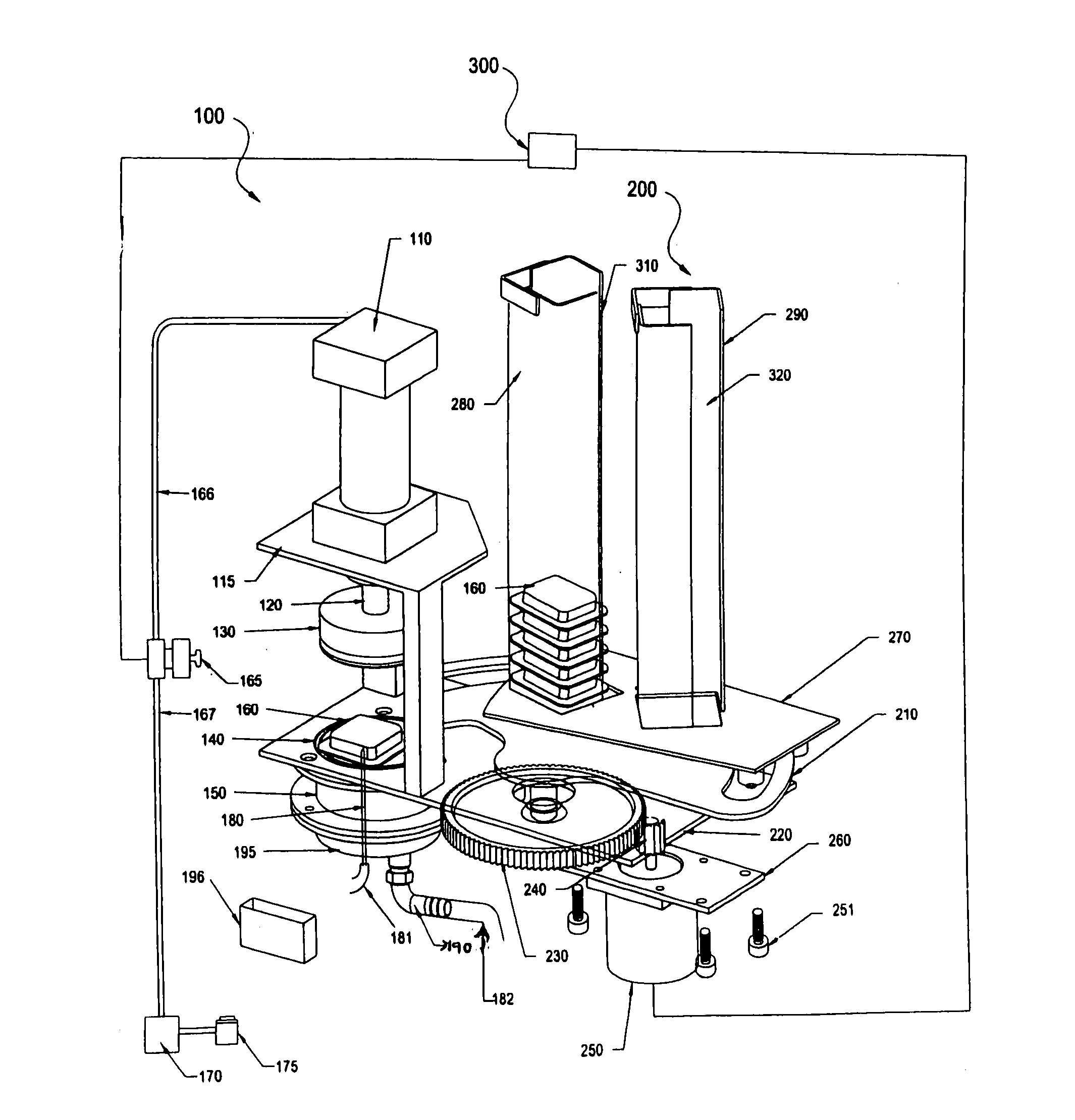

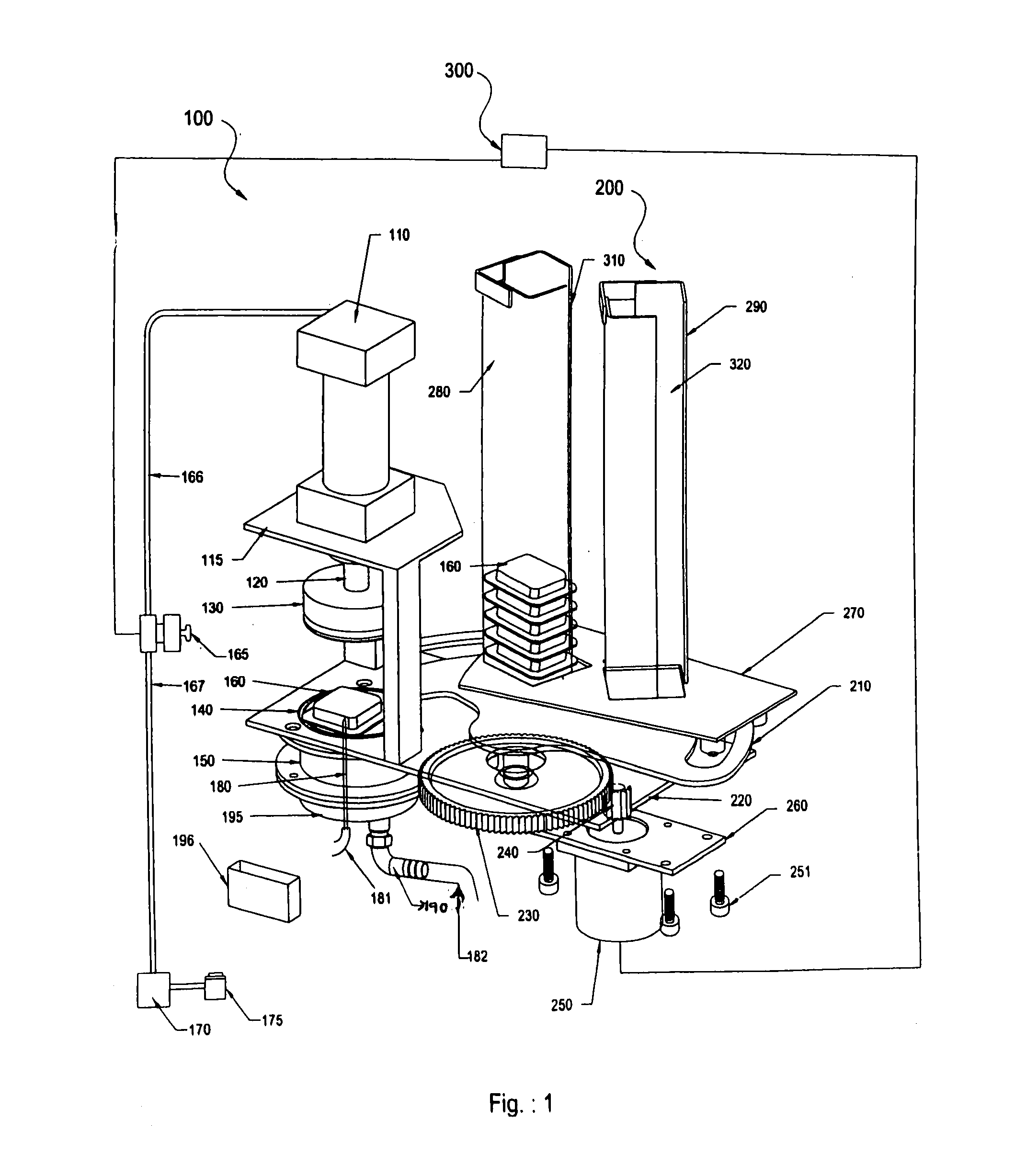

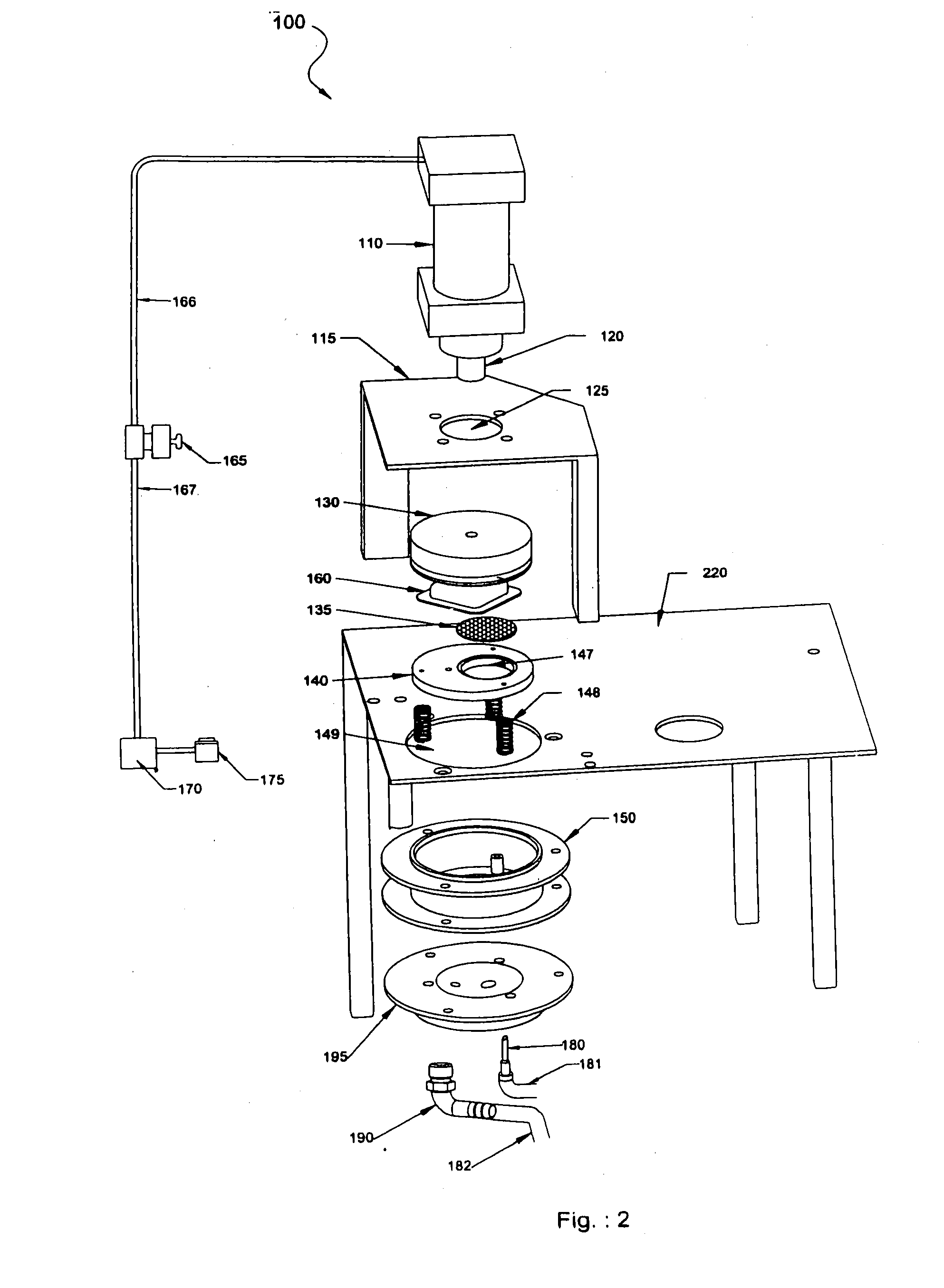

Automatic pod conveyor and brewer assembly for fresh hot beverage

This invention relates to an automatic pod-conveyor and brewer assembly for fresh hot beverage. The brewer sub-assembly (100) includes a pneumatic cylinder (110) with its piston rod (120) fitted to a brewer plunger (130). An injection nozzle (180) is detachably fixed from underneath to the brewer base (195) with its conical tip protruding into the brewer chamber (150). The single serving pod (160) is a receptacle (510) containing the brewing, infusible or other material (520), covered and sealed with a porous membrane (530). The injection nozzle (180) injects hot pressurized water, received through its interior from a suitable water heating system, into a single serving pod (160) placed within the brewer sub-assembly (100), and the brewed beverage flows out to a dispensing cup through a liquor outlet port (190) in the brewer base (195). The pneumatic cylinder (110) is operated by air solenoid valve (165) with compressed air from a compressed air storage tank (170). The pod-conveyor sub-assembly (200) includes a pod conveyor (210) which, by its rotational movement in a horizontal plane, conveys the pod (160) to the brewer sub-assembly (100) from chutes (280, 290). The pod-conveyor (210) is operated by a pusher motor (250) in co-operation with a pusher gear (230) fitted to the integral shaft (215) of the pod-conveyor (210). The assembly can be used to prepare hot beverage of a wide variety of brewing, infusible or other materials like tea, coffee, materials of plant origin such as floral pieces like Jasmine flowers, vegetable pieces like carrots, onions, materials of animal origin such as honey or other suitable beverage powder / material which can be placed in the single serving pod (160) of the assembly.

Owner:TATA GLOBAL BEVERAGES

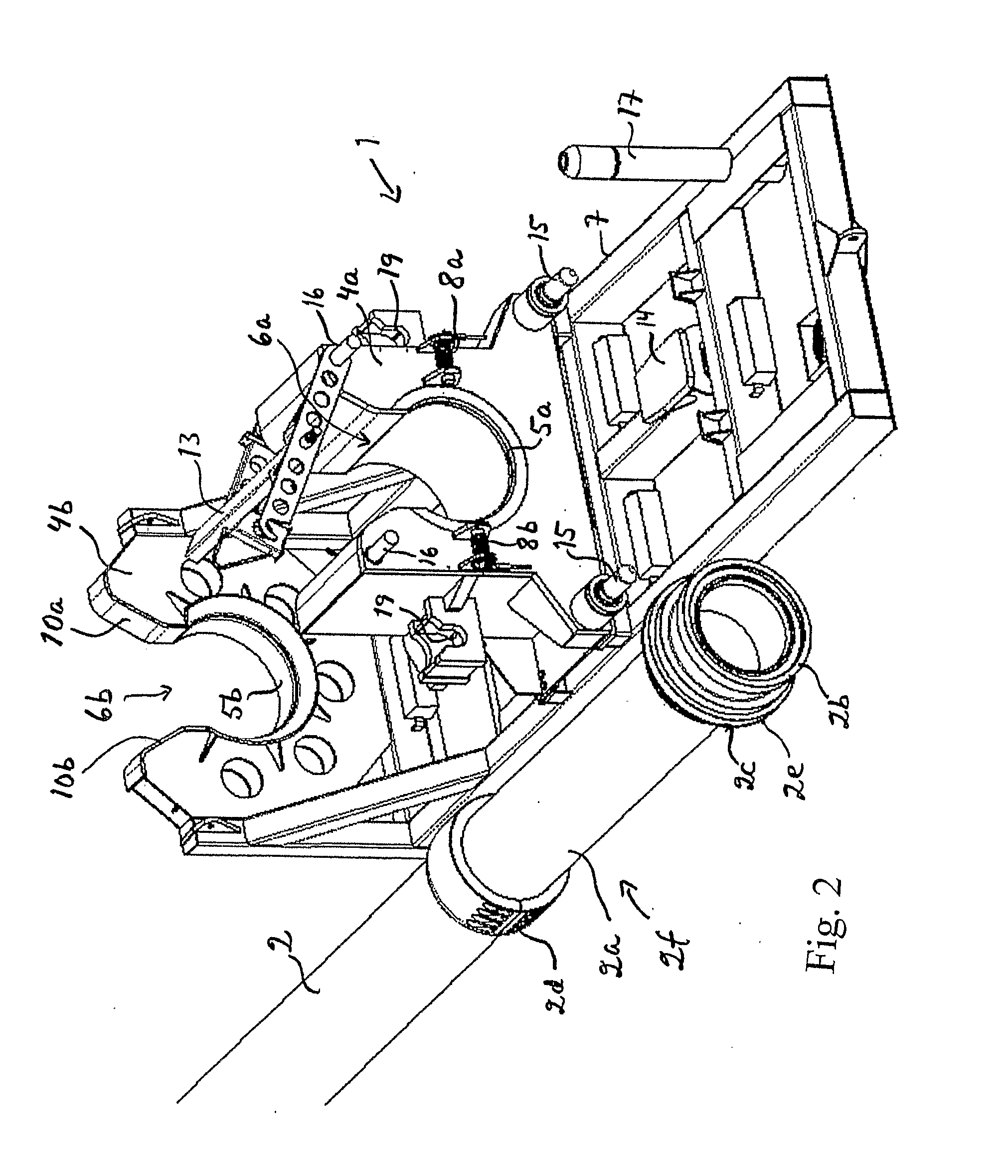

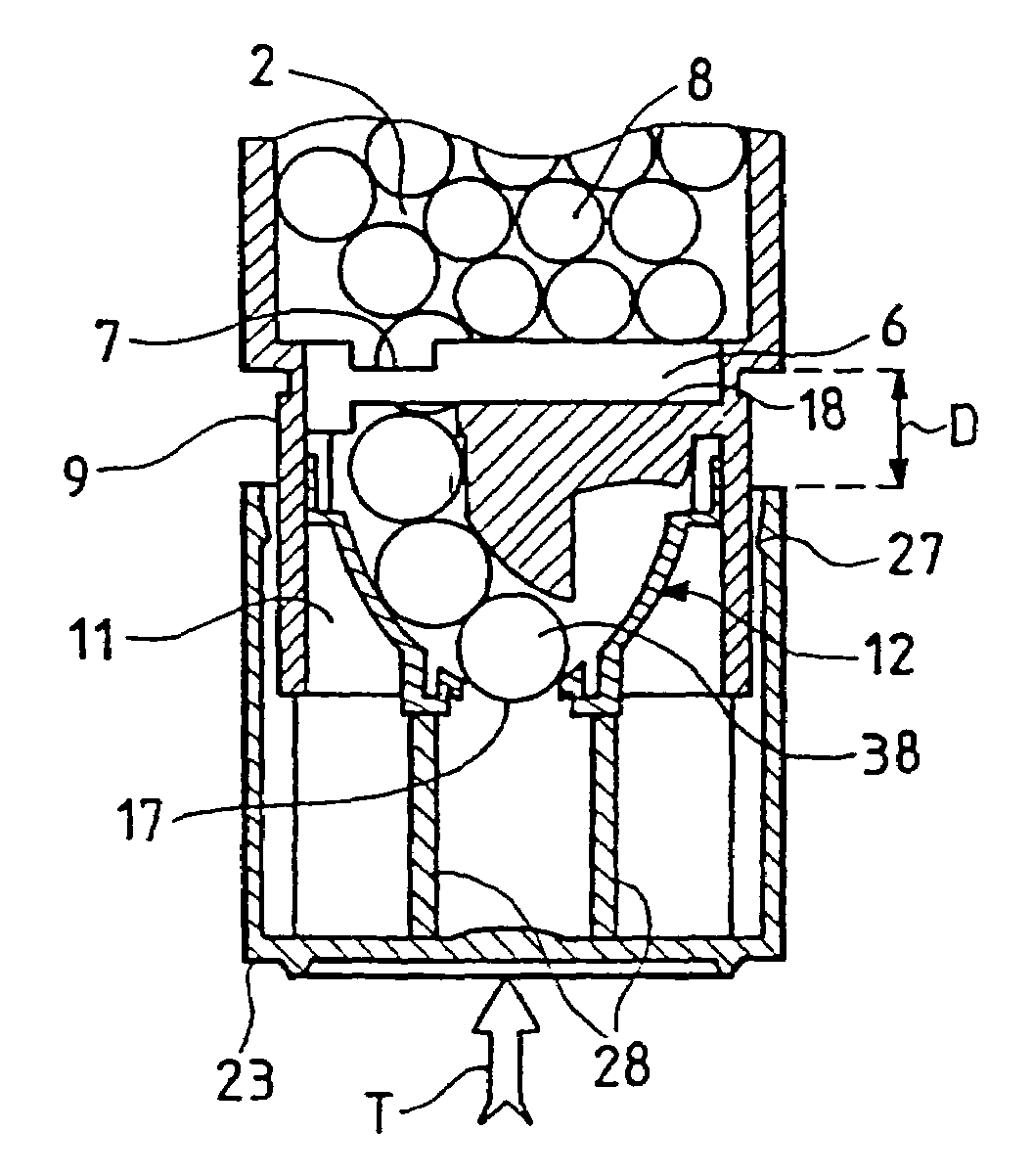

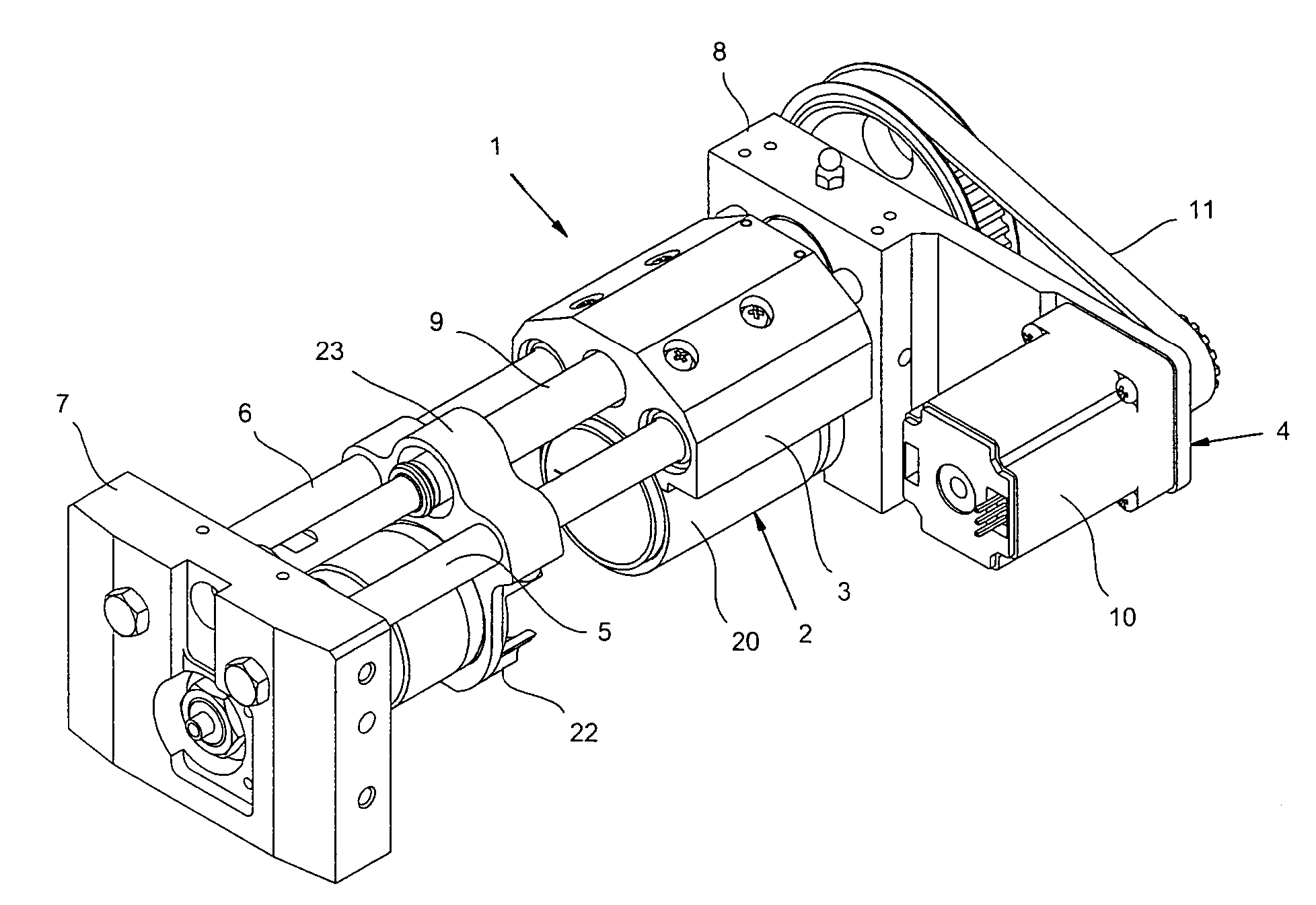

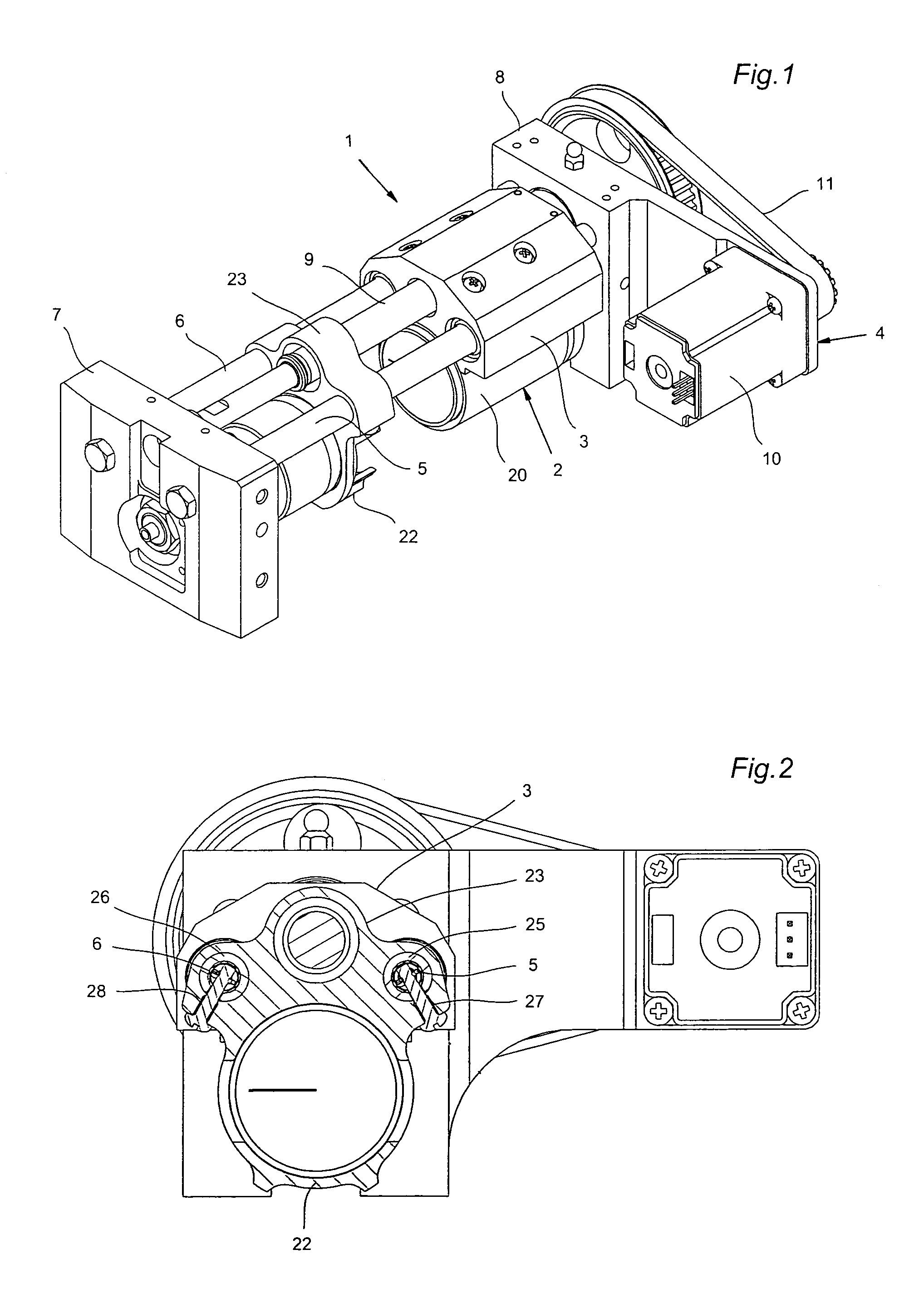

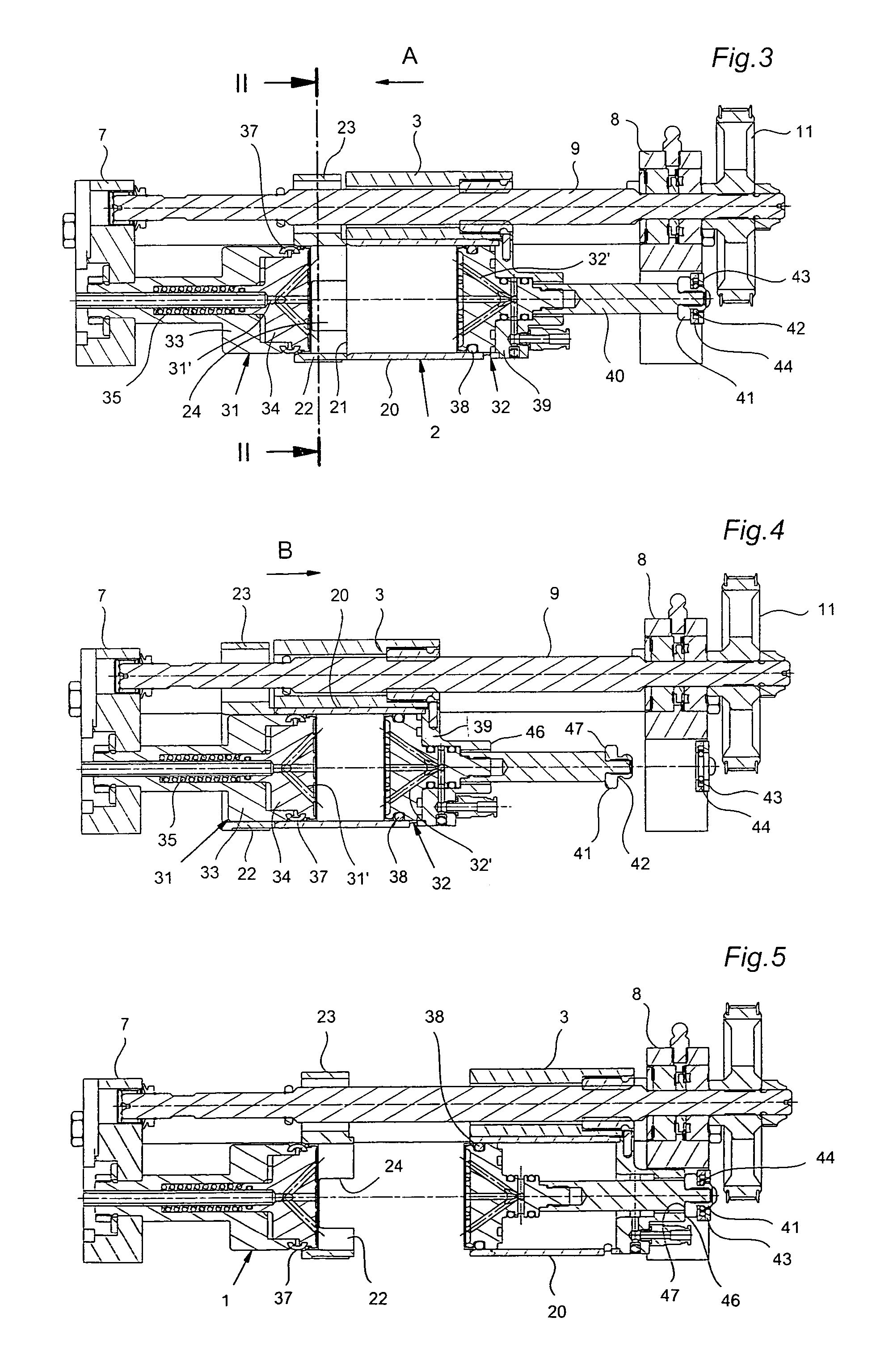

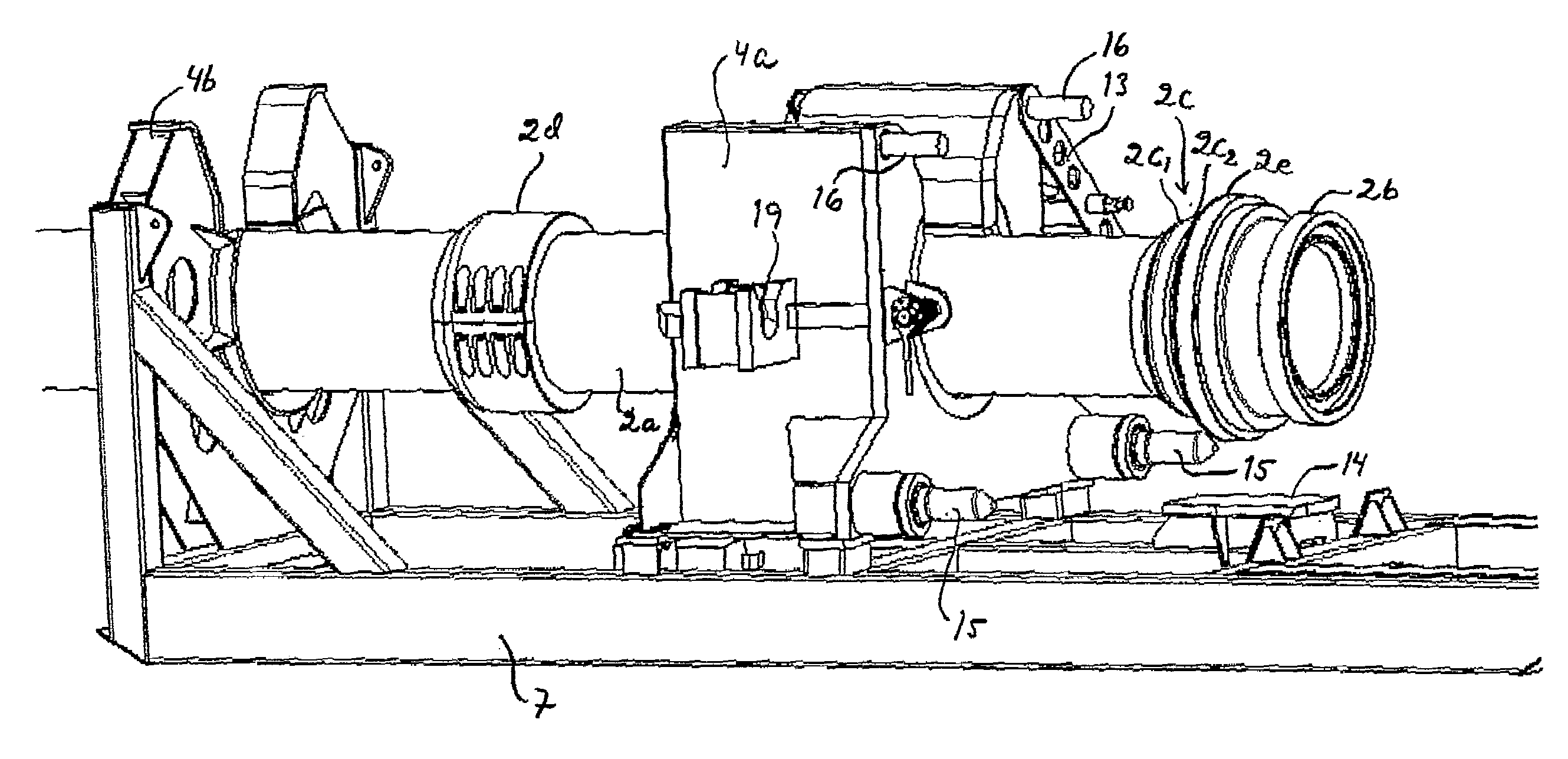

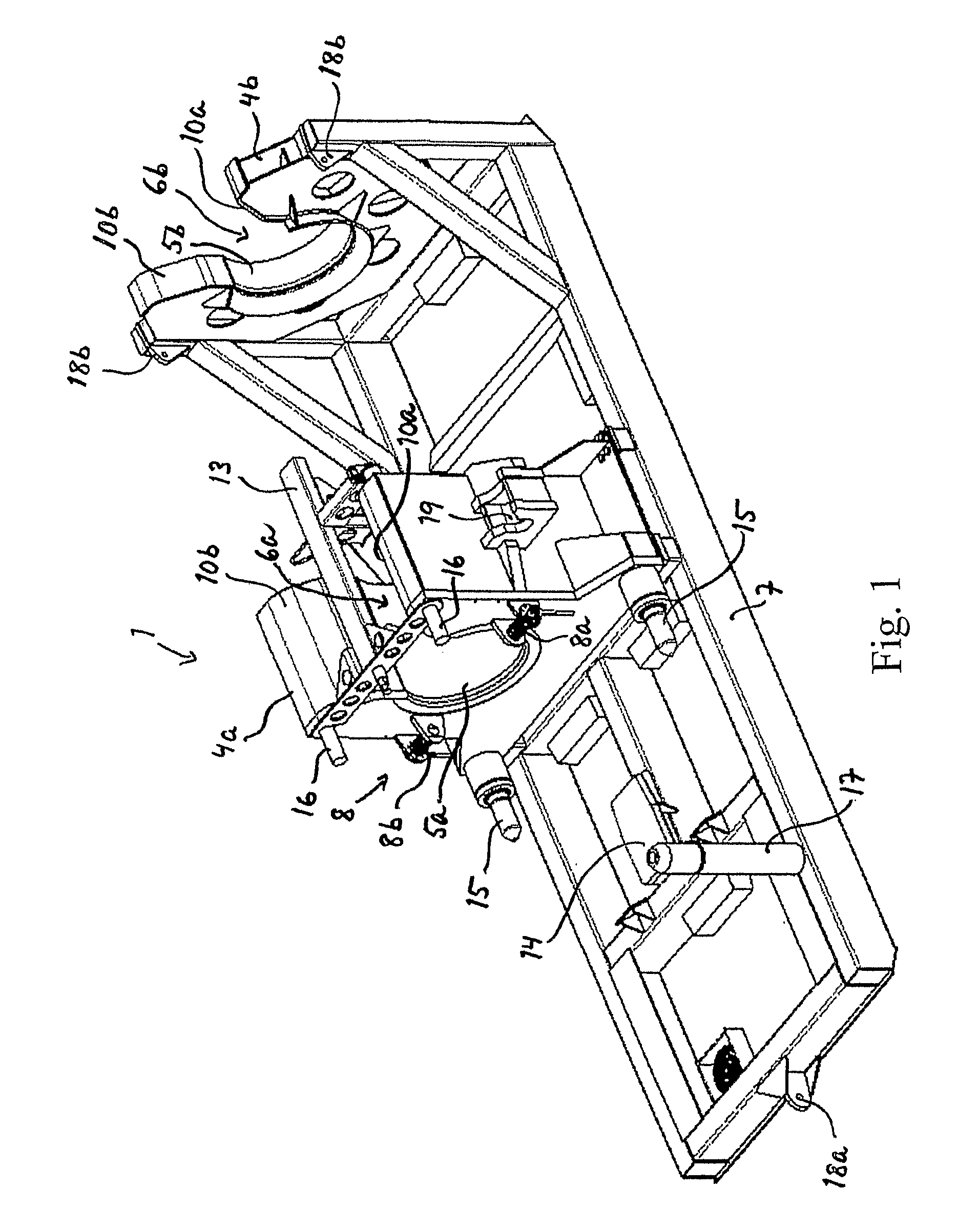

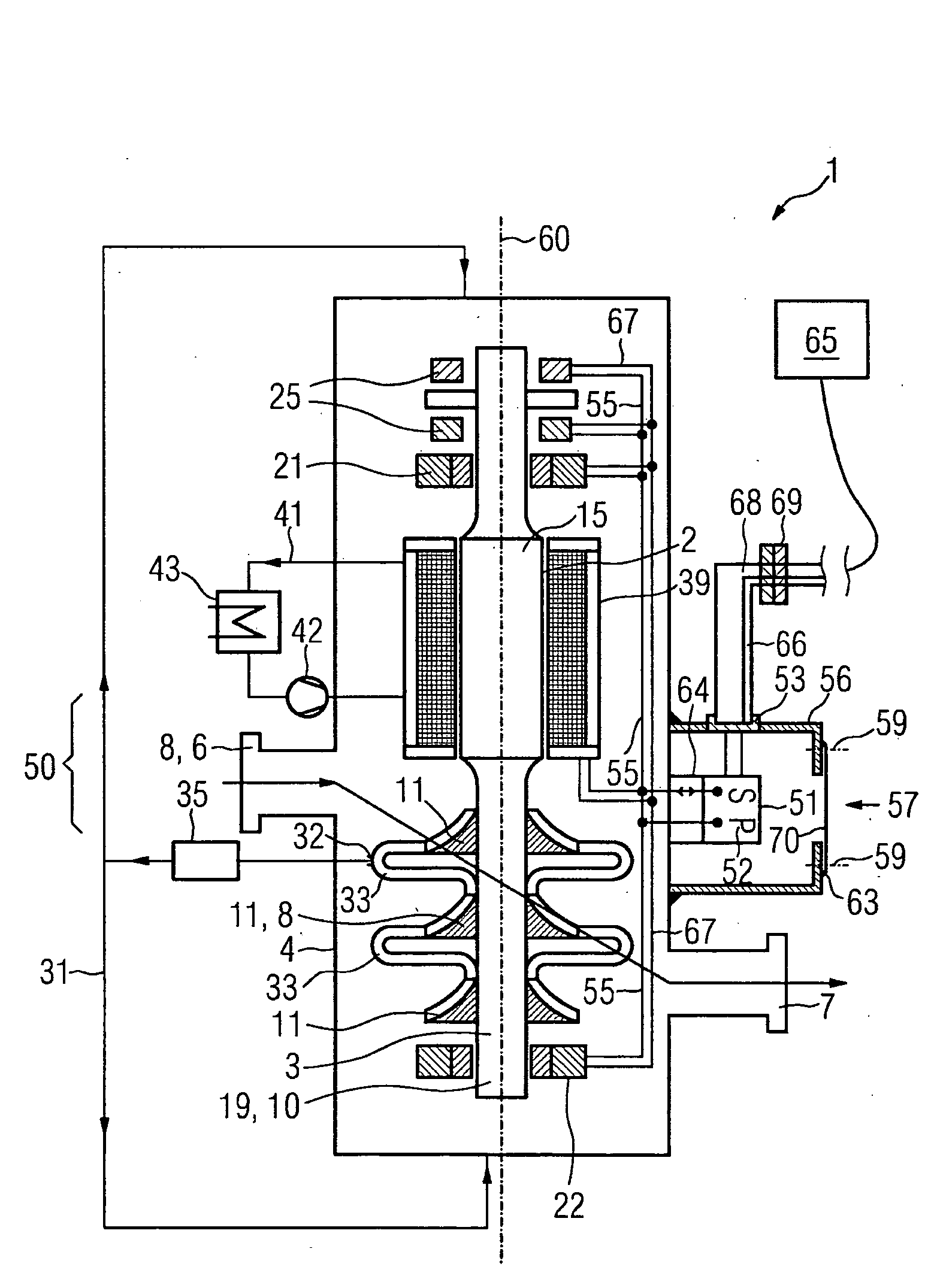

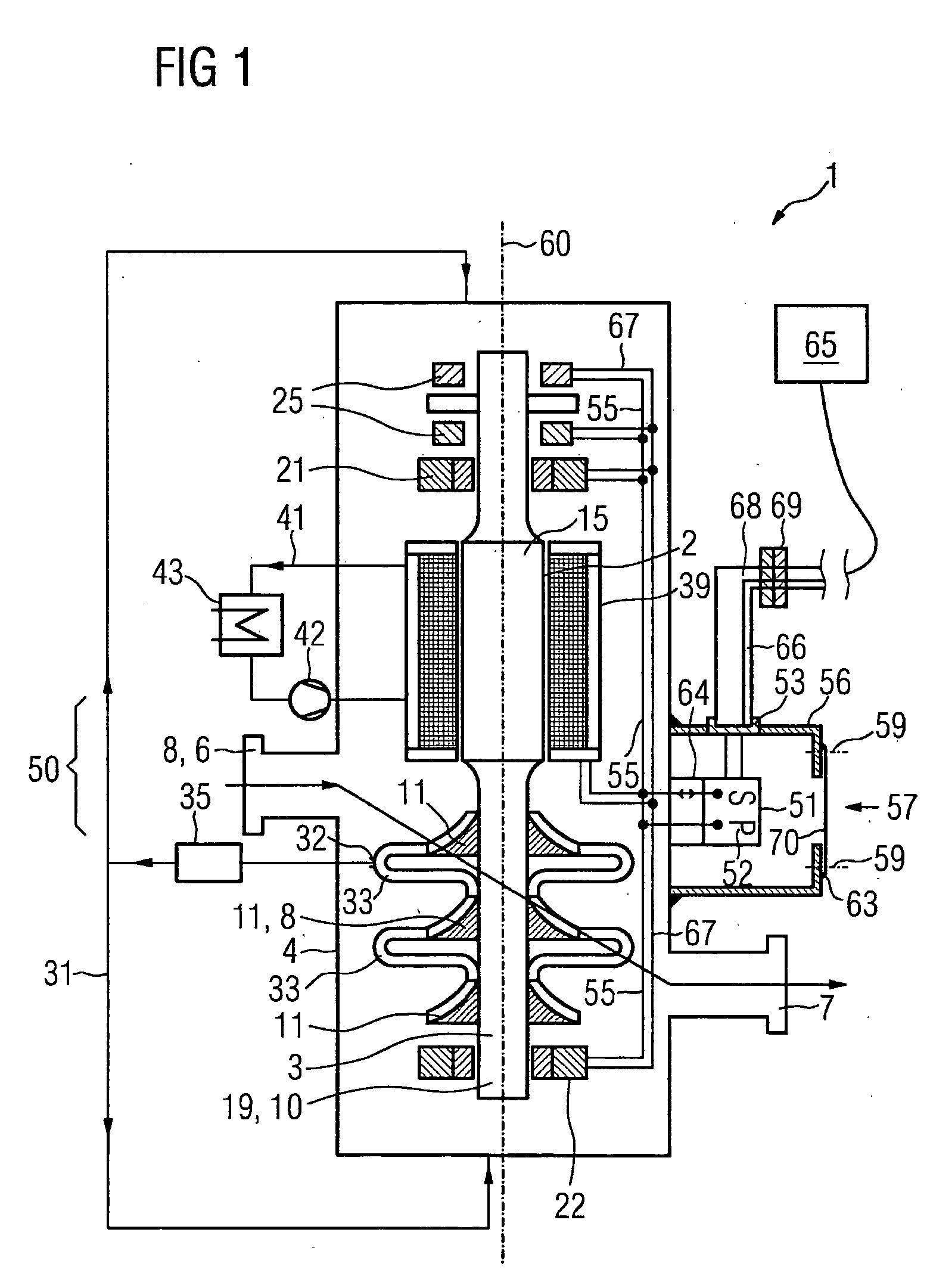

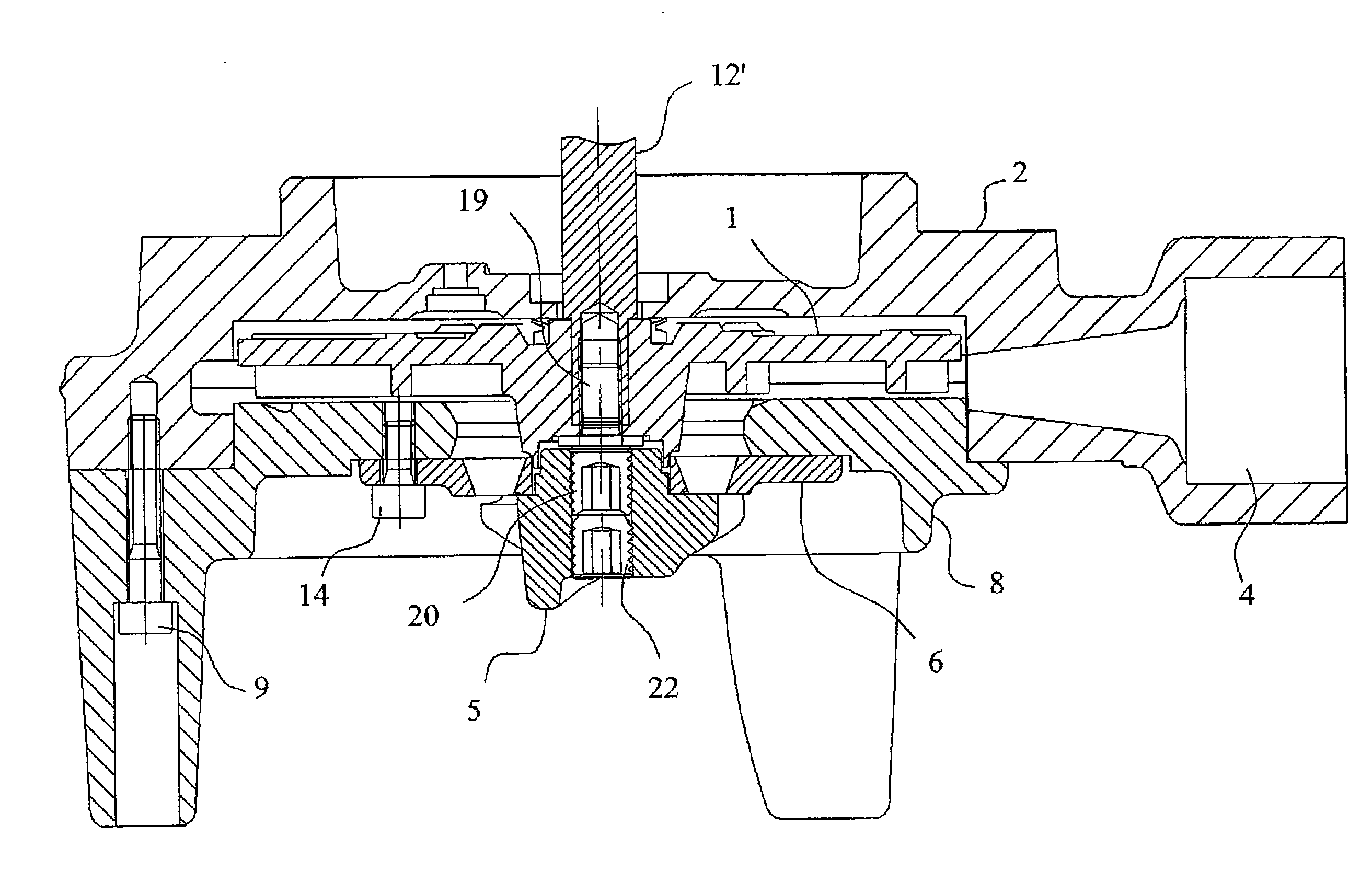

Extraction means for producing coffee for a coffee machine

InactiveUS7017474B2LengthShorten the lengthJuice extractionBeverage vesselsMechanical engineeringPiston

An extraction device for producing coffee for a coffee machine is equipped with a brewing cylinder (2) for receiving coffee powder. The brewing cylinder is reciprocably adjustable between pre-determined positions along its axial direction in co-operation with a drive mechanism (4). Two pistons (31, 32) that are coaxially adjustable relative to one another, are located in the brewing cylinder (2). The brewing cylinder (2) incorporates a cylinder section (20), and an additional part (22) is also envisaged. The additional part (22) is moveably located at an end of the brewing cylinder (2) that can be closed by the first piston (31) and equipped with a filler opening (24) for the insertion of the coffee powder. In this way the length of the extraction device can be shortened.

Owner:STEINER WEGGIS AG

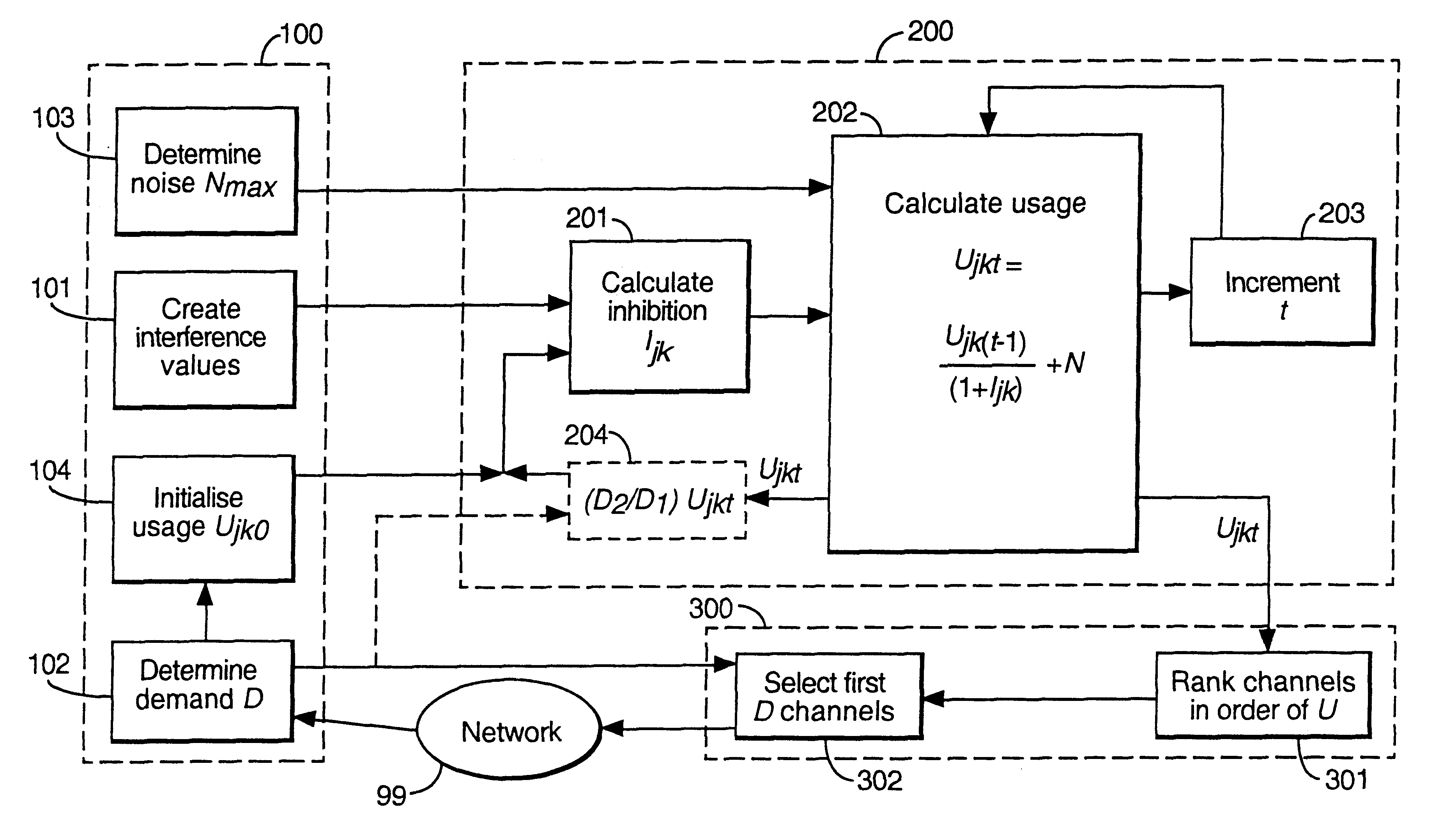

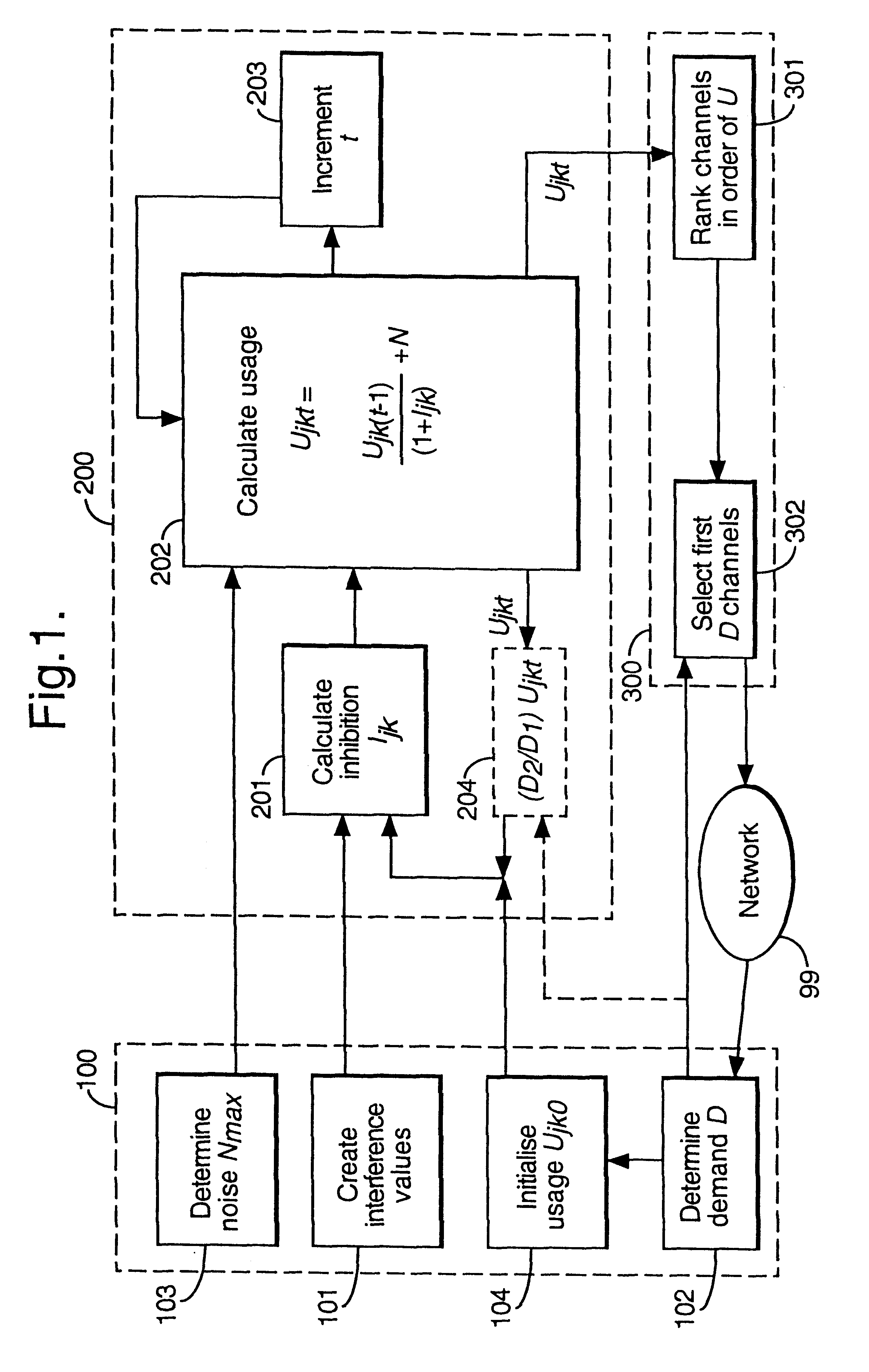

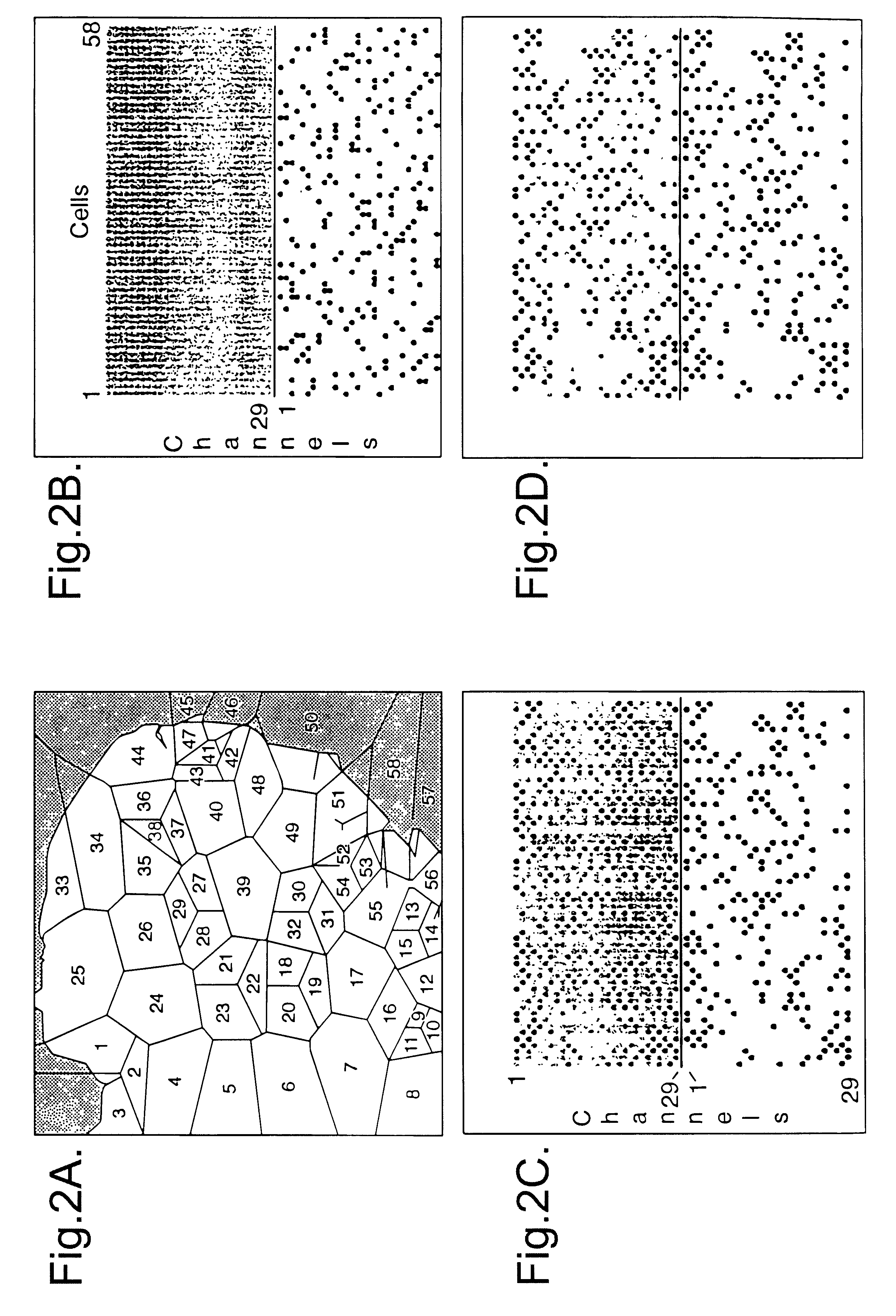

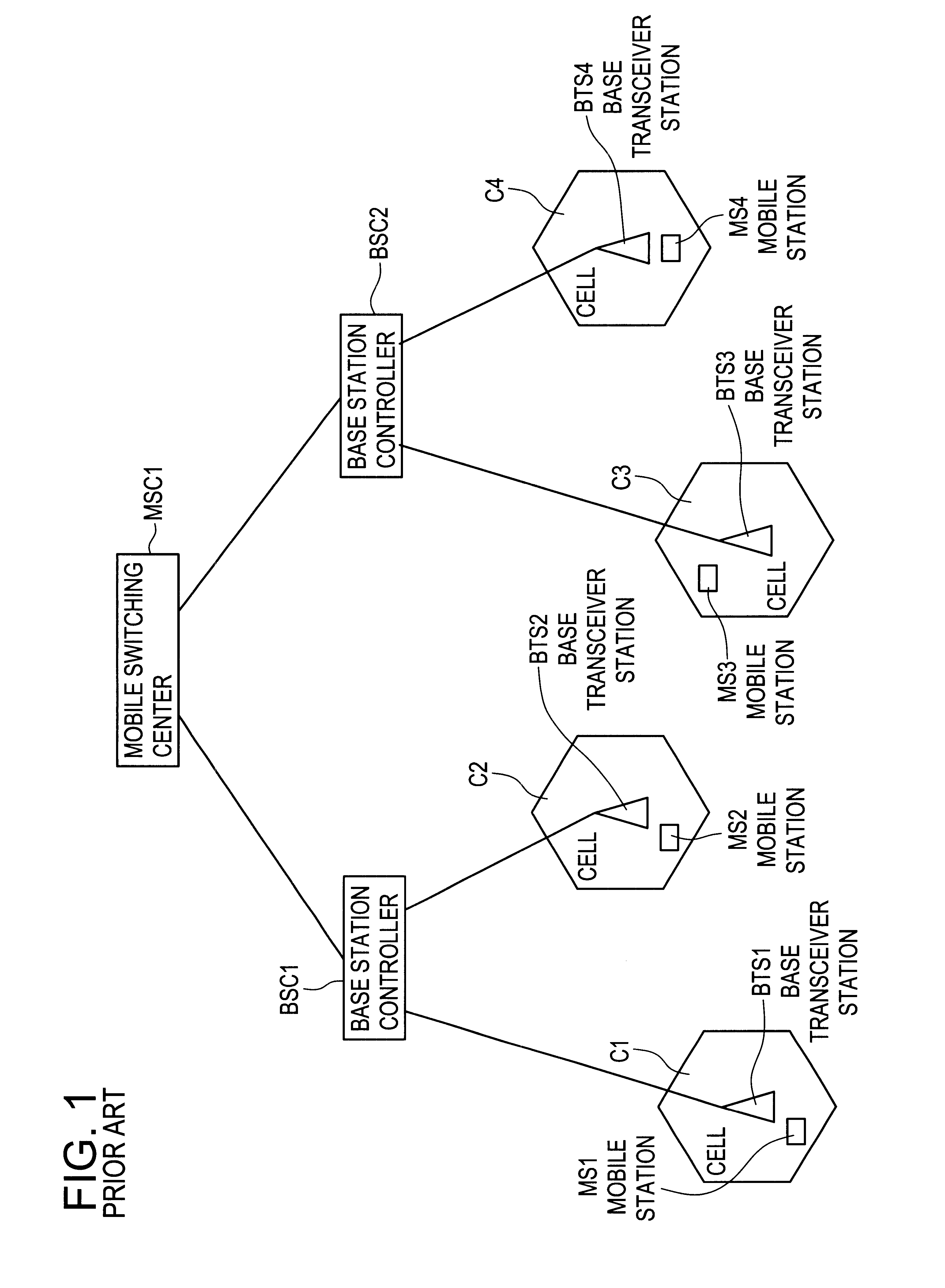

Channel allocation in cellular telephony

InactiveUS6539228B1Network traffic/resource managementRadio/inductive link selection arrangementsRankingMedium range

A channel allocation process for a cellular telephone network starts from a position of homogeneity in which each base station has the potential to use all channels. It develops ever greater heterogeneities by processing a combination of short and medium range interactions between the base stations themselves, causing each base station of the cellular telephone network to inhibit its neighbors from using a given channel, to generate a usage factor for each channel in each cell indicative of the level of interference to be expected on that channel in that cell. Channels can then be allocated to each base station according to the ranking of the usage factors determined for the channels at that base station. The entire network may be emulated by a single processor, controlling the base stations of the network in accordance with the results of the process. Alternatively, each base station of the network performs that part of the process relating to itself, in co-operation with its neighbors, and utilizes channels in accordance with results.

Owner:BRITISH TELECOMM PLC

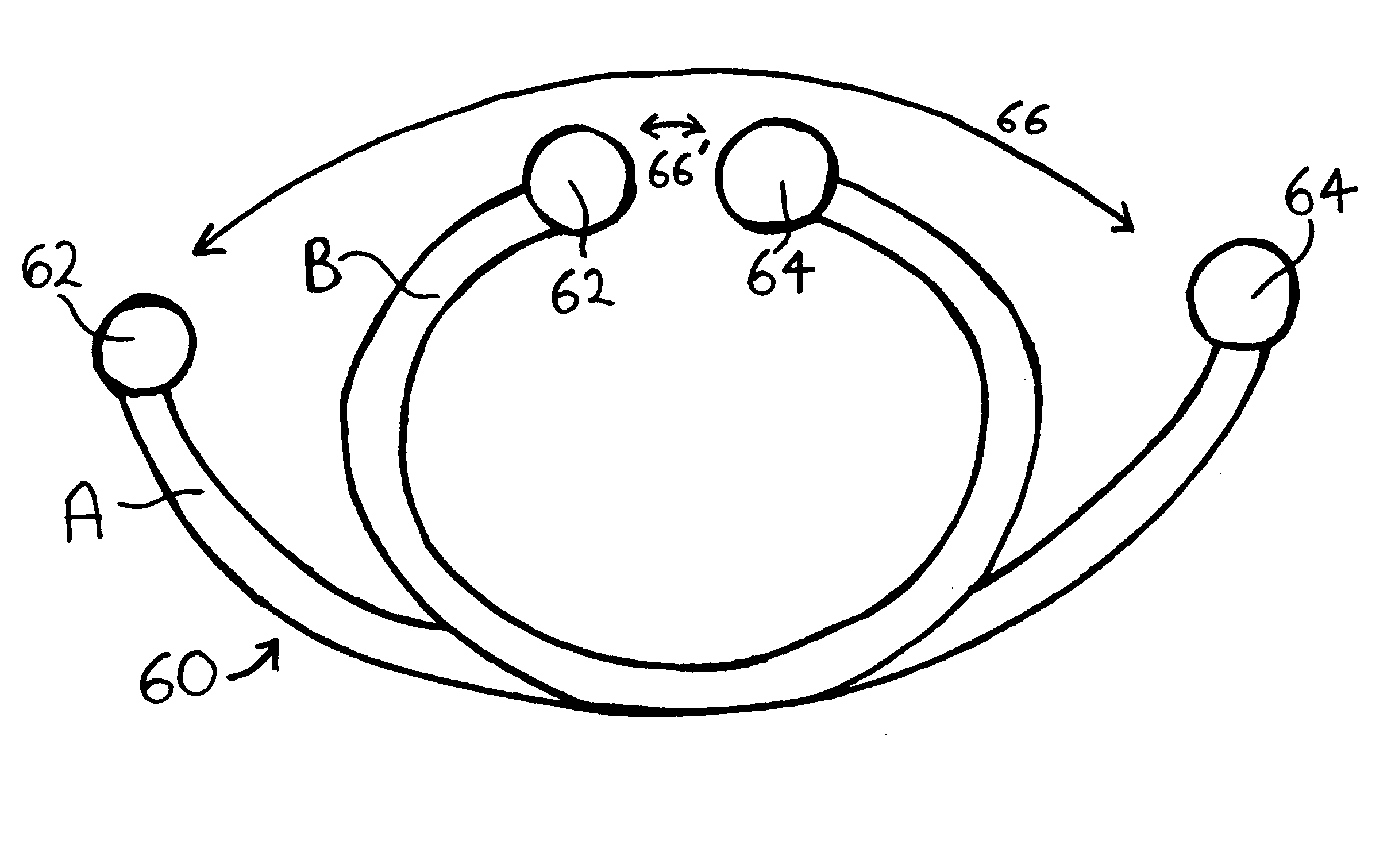

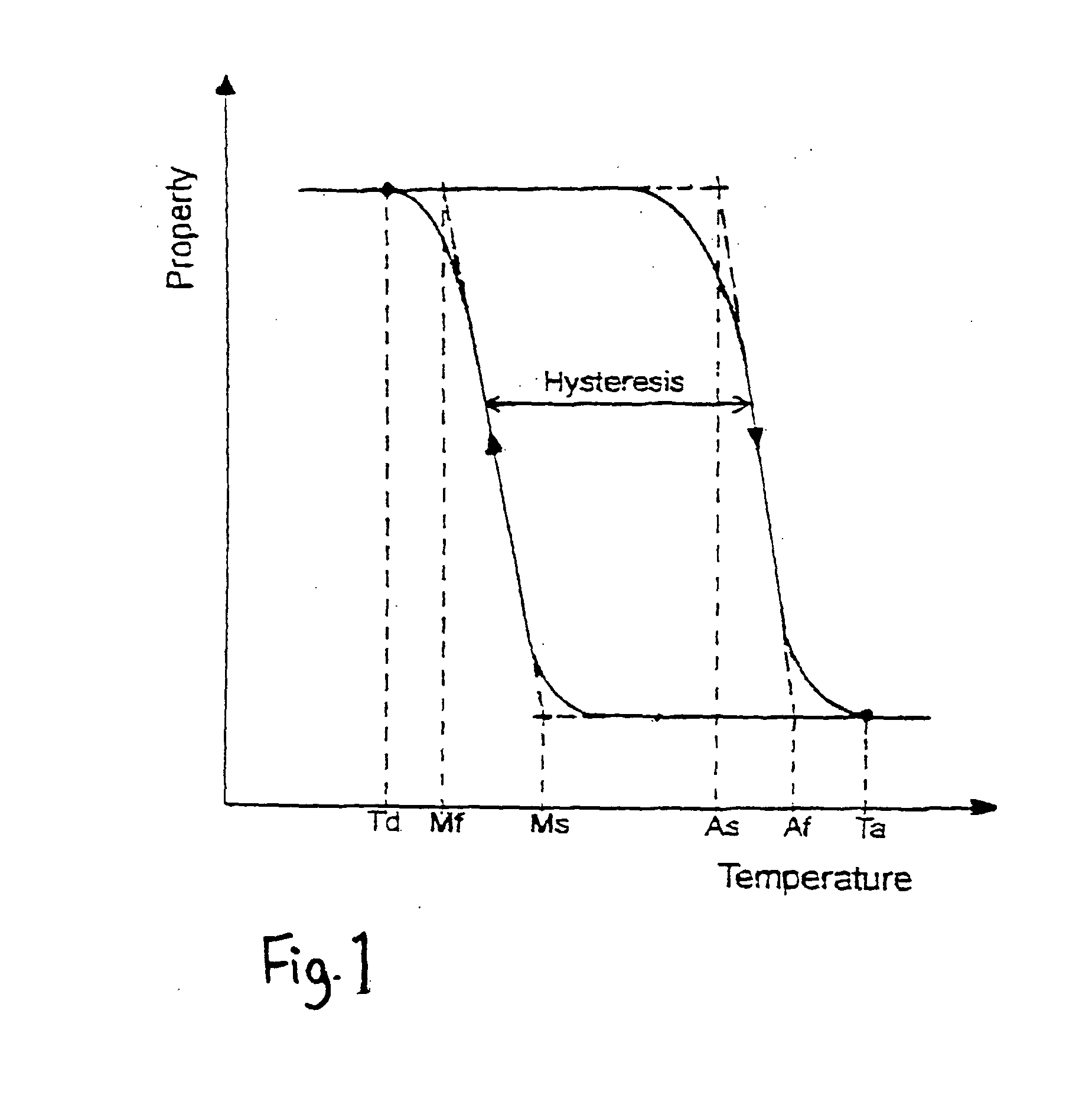

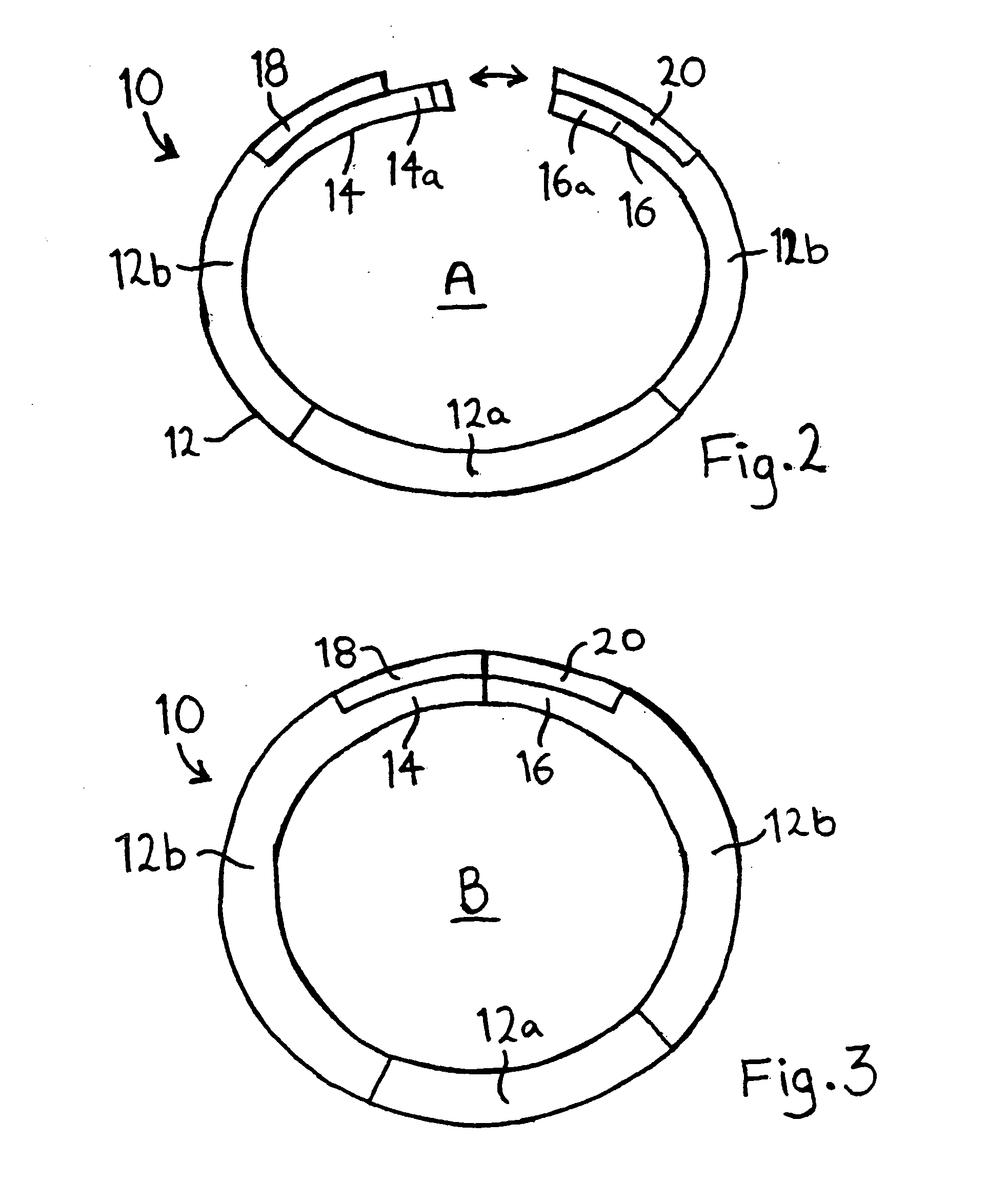

Jewelry arrangements

A piece of jewelry (10) is disclosed, comprising first and second substantially opposing end portions (14, 16), at least one said end potion being moveable from an open state A in which said end portions (14, 16) are spaced apart towards a closed state B in which said end portions (14, 16) are spaced apart by, a reduced gap or are substantially engaged. The piece of jewelry (10) comprises at least a section (12a) made from a shape memory material and said shape memory material is adapted, at or above a predetermined temperature Ta, to bring said end portions (14, 16) towards each other. This occurs preferably when said shape memory material is placed in the region of a body part of a wearer such that shape memory effect is used in co-operation with body temperature to fit said piece of jewelry to its wearer whist simultaneously causing, a change in externally visible shape or configuration or the jewelry.

Owner:THIERRY HOLEMANS +2

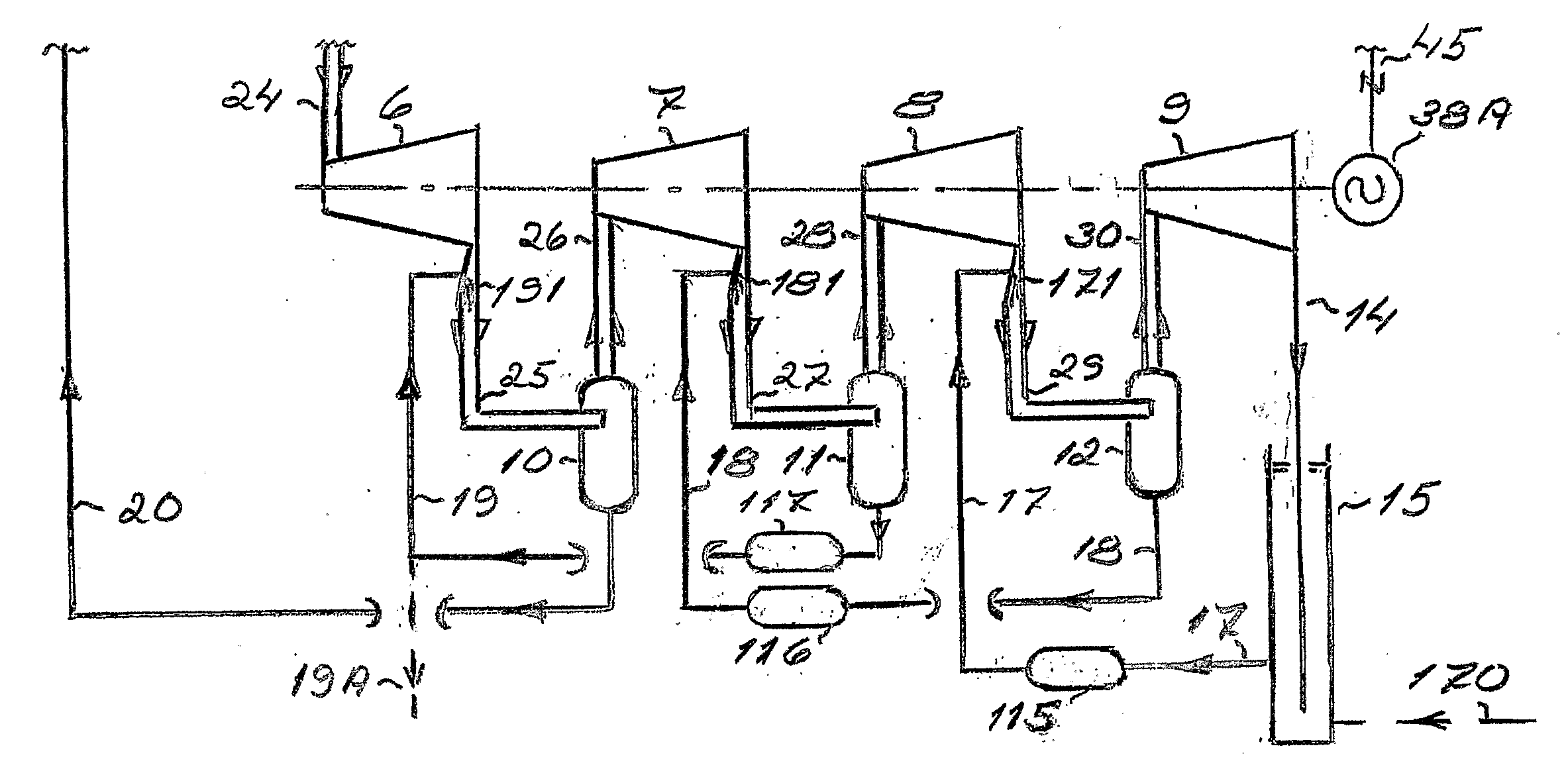

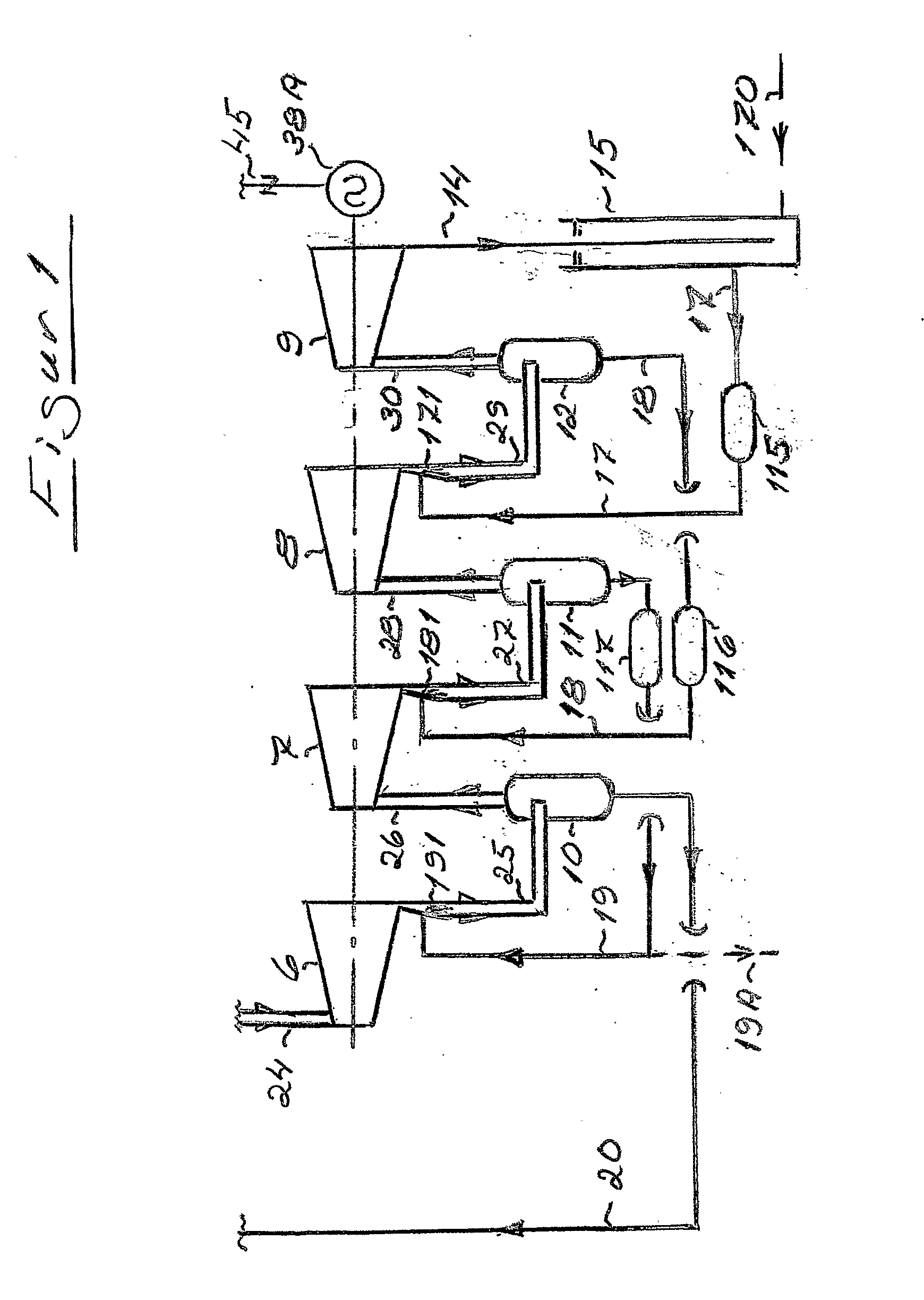

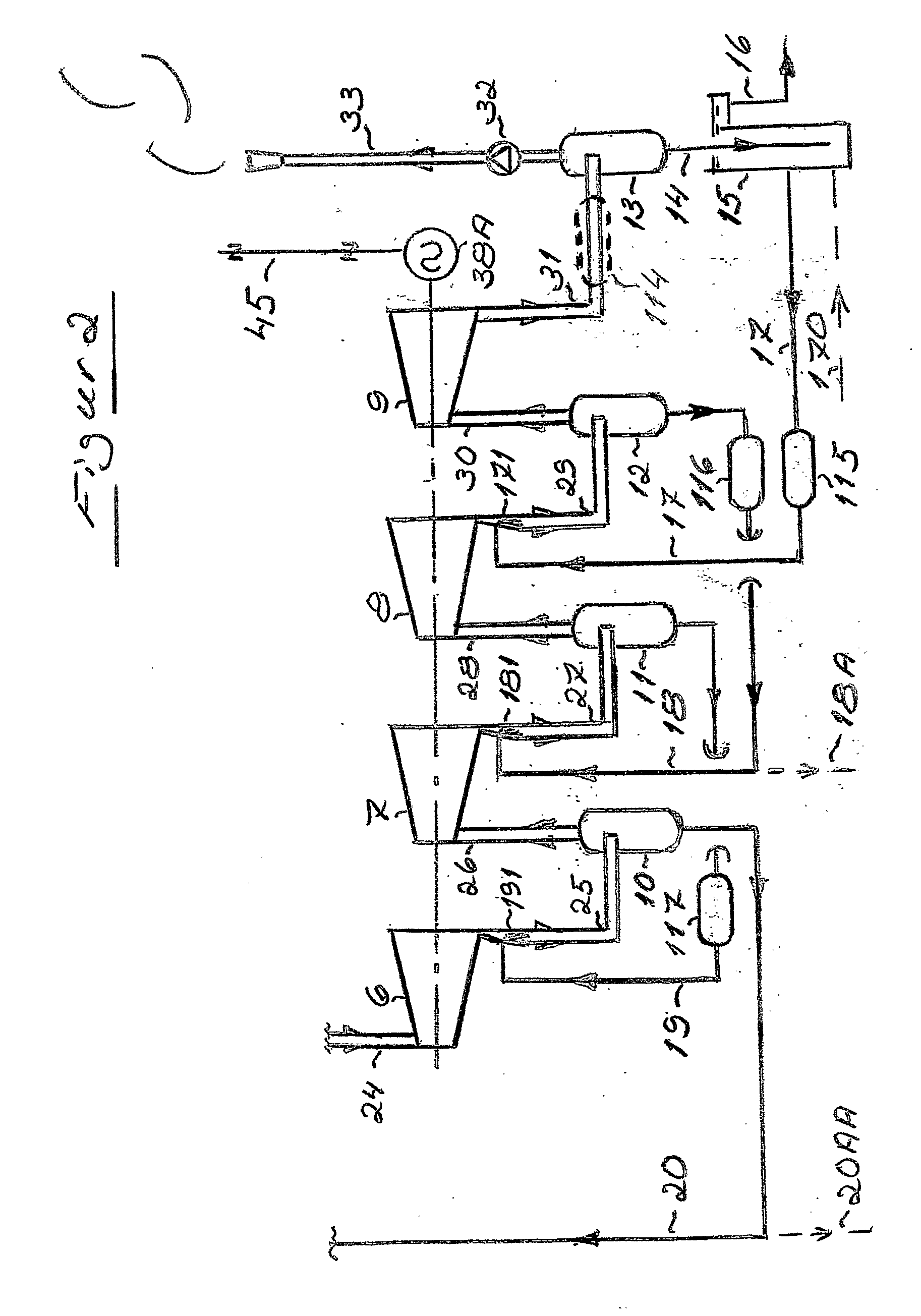

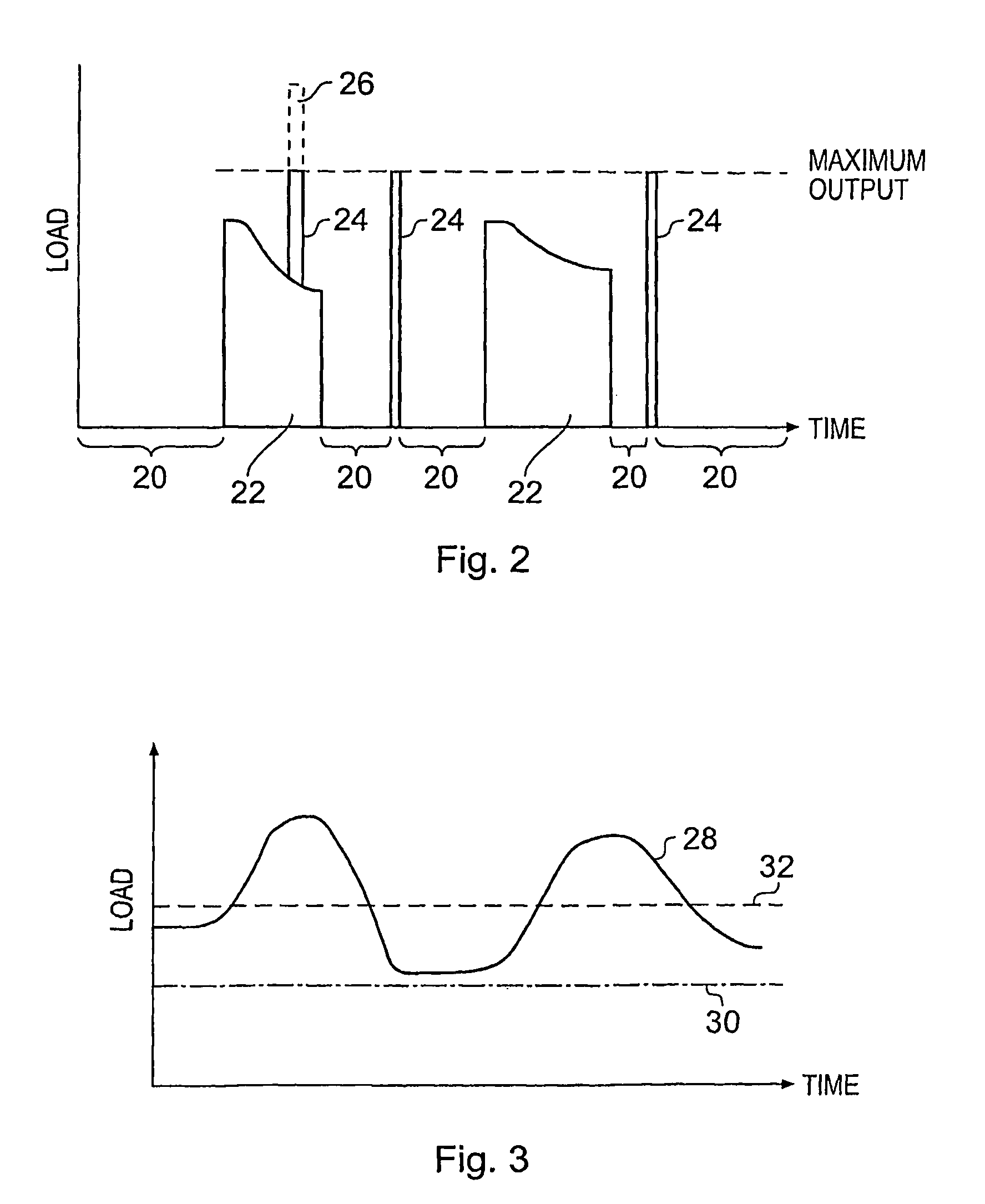

Method and Arrangement for Energy Conversion in Stages

InactiveUS20090019853A1Efficient conversionImprove energy efficiencyReciprocating combination enginesCombination enginesHybrid typeSustainable economy

A flexible method and arrangement provides an effective conversion of energy from any kind of energy sources and / or fuels by combustion and / or gasification, during long-term sustainable economy and environment, by energy conversion in stages. With an open partially circulated condensate system and / or a closed circulation feed water system, stages include first stage of conversion by gasification / combustion, pressurized and / or atmospheric with or without steam- and / or gas-turbines and / or pressurized fuel cell, followed by a second stage of conversion, which second stage utilizing condensation cooling including direct and / or indirect heat transmissions by the first stage produced pressurized mass flow of primary / secondary / residual heat comprising sensible and latent heat, by means of arrangement of expander turbines including counter current fed feed water / condensate fractions during preheating of condensate and feed water respectively before the return to the first stage of conversion. The expander turbines of the second stage with or without co-operation by a third stage of integrated heat transmissions together with the first and second stages effectively transform the mass flow of primary / secondary / residual heat / gas into bio-fuels, mechanical energy as electric power via turbine connected generators, or driving mobile machines / vehicular—a hybrid type of rotation motor during continuous combustion.

Owner:NILSSON BENGT

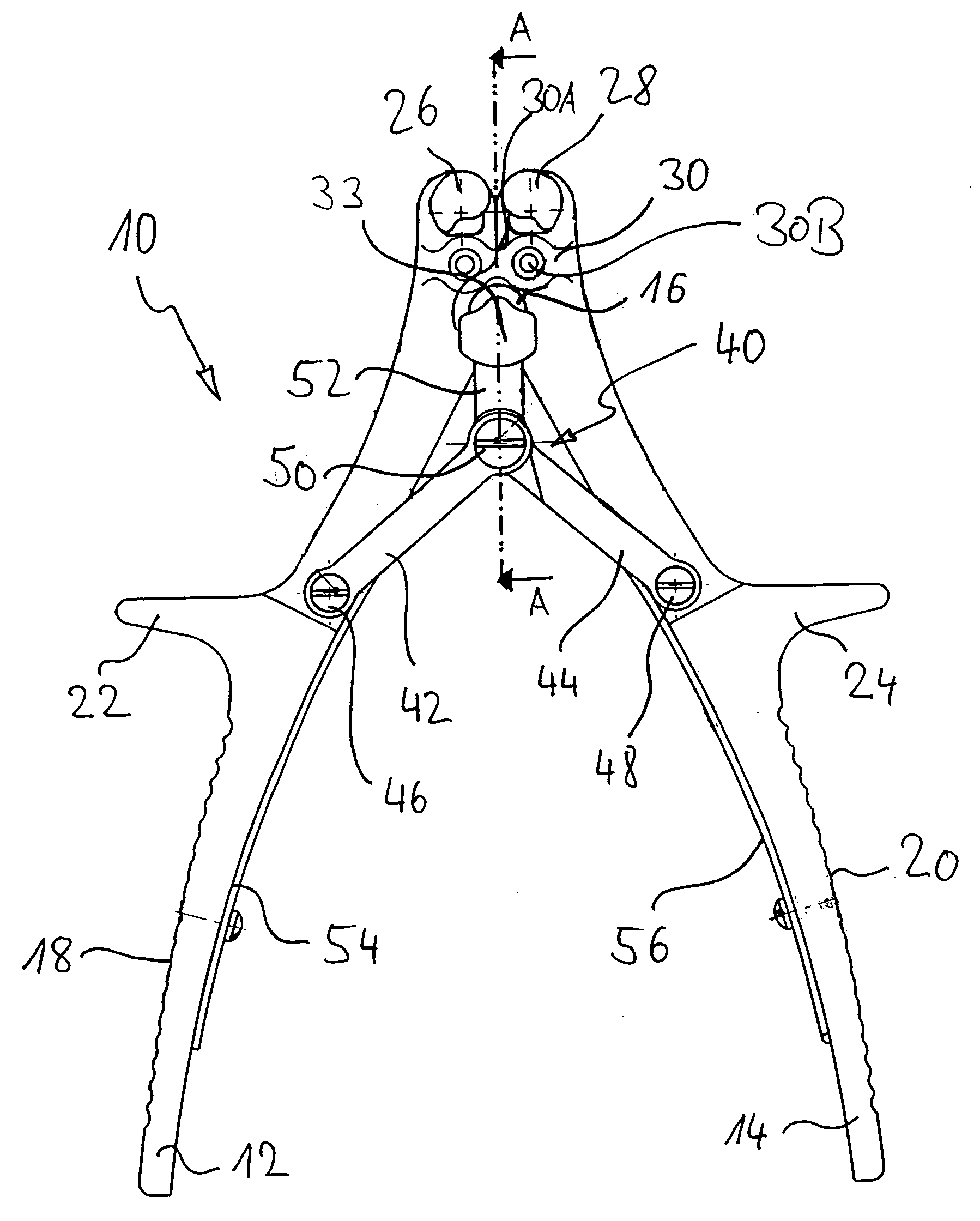

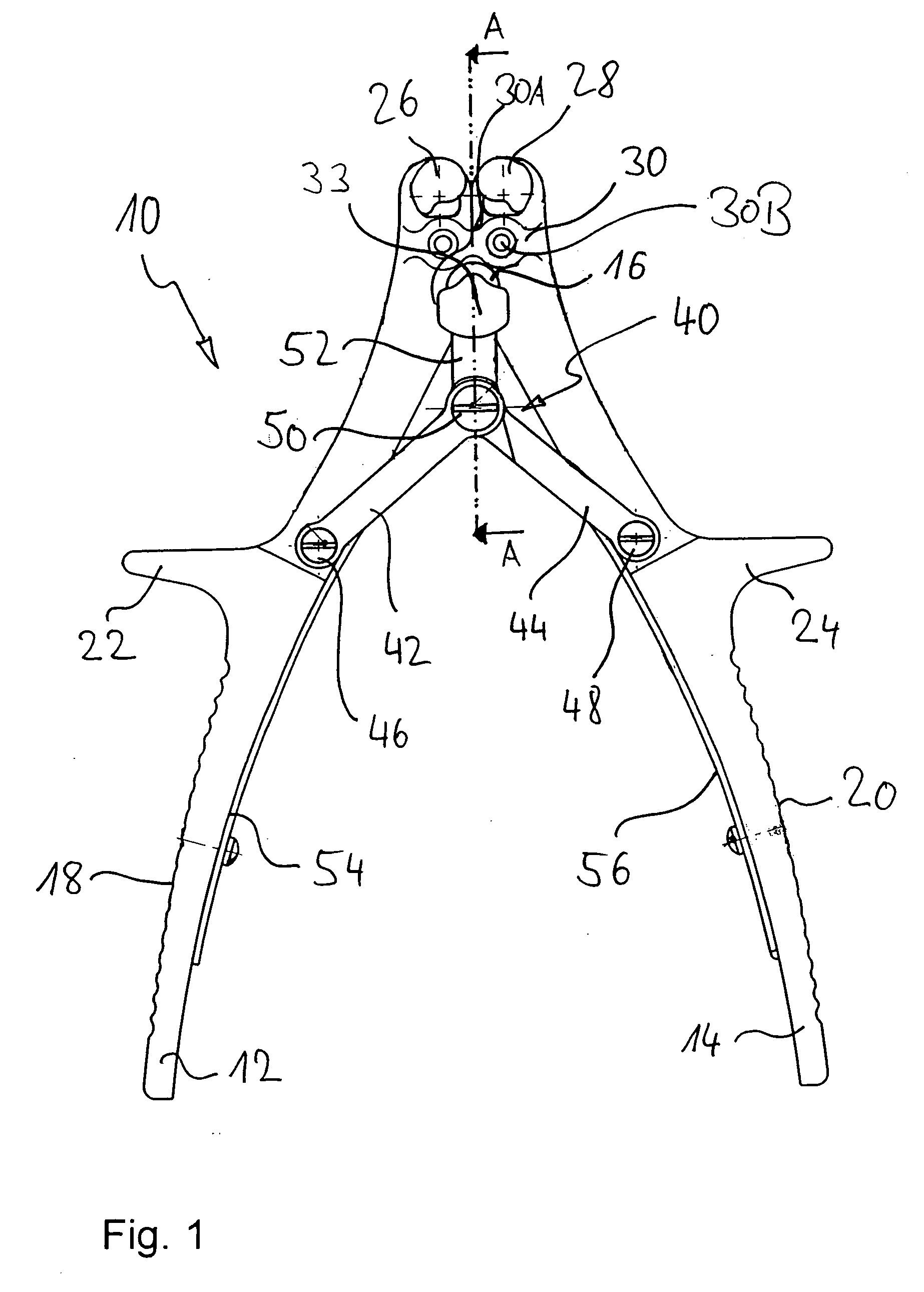

Surgical Bending Forceps and Bending Forceps System

ActiveUS20090222020A1Simple handlingSimplify manipulationProsthesisOsteosynthesis devicesSurgical operationForceps

Bending forceps (10) for surgical elements such as bone plates (30) are described. The bending forceps (10) have two branches (12, 14) which can pivot relative to one another and with together two counter bearings (26, 28) for the surgical element to be bent. A bending punch (32) for co-operation with the surgical element is provided in a region between the two counter bearings (26, 28). An actuating movement (40) of the branches (12, 14) is converted into a linear movement of the bending punch (32) in the direction of the surgical element by means of an actuating device (40), for example an elliptical linkage gear mechanism.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Battery pack and cooling system for a battery pack

A battery pack and a cooling system for a battery pack that includes a plurality of battery cells, the battery pack including a plurality of battery cells; a first refrigerant circulation pipe; and a second refrigerant circulation pipe adjacent to the first refrigerant circulation pipe, wherein the first refrigerant circulation pipe is configured to direct a refrigerant along a first circulation pathway, the second refrigerant circulation pipe is configured to direct the refrigerant along a second circulation pathway counter to the first circulation pathway, and at least one of the first refrigerant circulation pipe and the second refrigerant circulation pipe is in thermal co-operation with the battery cells.

Owner:SAMSUNG SDI CO LTD +1

Pipeline termination skid, a connection arrangement comprising such a pipeline termination skid and a pipeline termination

ActiveUS7503727B2Reduce demandEasy to operatePipe laying and repairFlanged jointsOcean bottomEngineering

A pipeline termination skid to be mounted to a pipeline end section to support a pipeline hub during the connection of the pipeline hub to a corresponding spool piece hub. The pipeline termination skid is so designed that a pipeline end section may be mounted thereto subsea by lowering the pipeline end section into a seat of one or several holding devices of the pipeline termination skid and thereafter displacing the pipeline termination skid along the pipeline end section so that the respective seat is brought into engagement with an alignment element secured about the pipeline end section so as to thereby fix the pipeline end section axially and radially in relation to the pipeline termination skid. A connection arrangement includes the pipeline termination skid, a pipeline termination designed for co-operation with the termination skid and a method for subsea connection of a pipeline to a spool piece.

Owner:VETCO GRAY SCANDINAVIA

Illumination of signs and system for providing signs

InactiveUS20040037077A1Increase supplyEasily customisedNon-electric lightingLighting support devicesEngineeringSolid-state

A sign illumination kit includes lamp support means adapted to be trimmed for location in co-operation with structure defining a sign or sign segment. Means forming, or divisible to form, a plurality of illumination elements each has a mount component and one or more solid state lamp devices mounted thereon, which elements may be arranged in sets of varying size and shape. Means is provided for attaching the illumination elements to lamp support means in an assembly in which the solid state lamp devices when activated cause the sign or sign segment to be illuminated.

Owner:SHOWERS INT

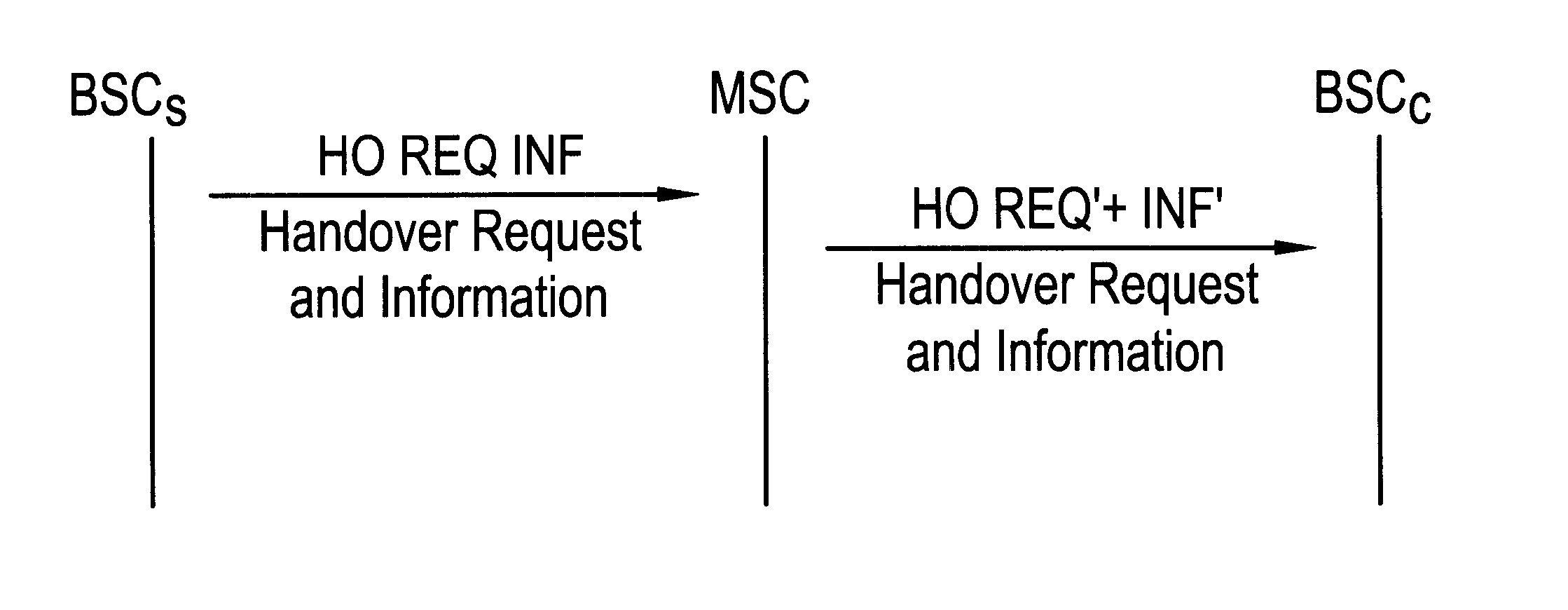

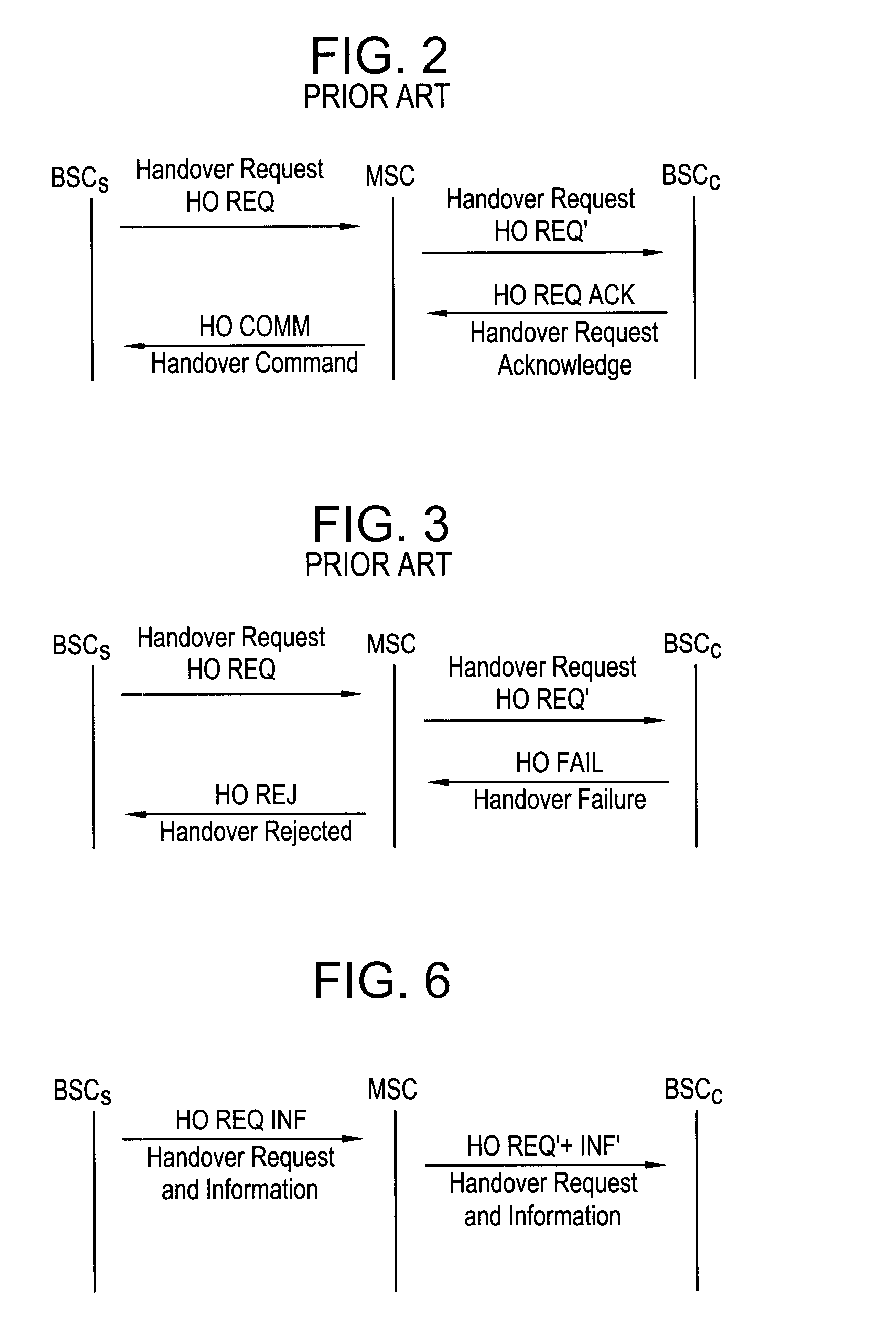

Method of improving cooperation between entities during call handover

InactiveUS6493555B2Easy to operateCooperate wellRadio/inductive link selection arrangementsRadio transmissionMobile radioHandover

A method of improving co-operation between entities in a cellular mobile radio communications network, wherein during inter-cell call handover, a new server cell is chosen from a set of candidate cells as being a candidate cell to which a requested handover is possible, and candidate cells to which a requested handover is not possible are referred to as rejected cells. When executing an external call handover from a current server cell controlled by a current server entity to a new server cell chosen from the set of candidate cells and controlled by a new server entity which is distinct from the current server entity, the new server entity is informed of any previously rejected cells.

Owner:ALCATEL LUCENT SAS

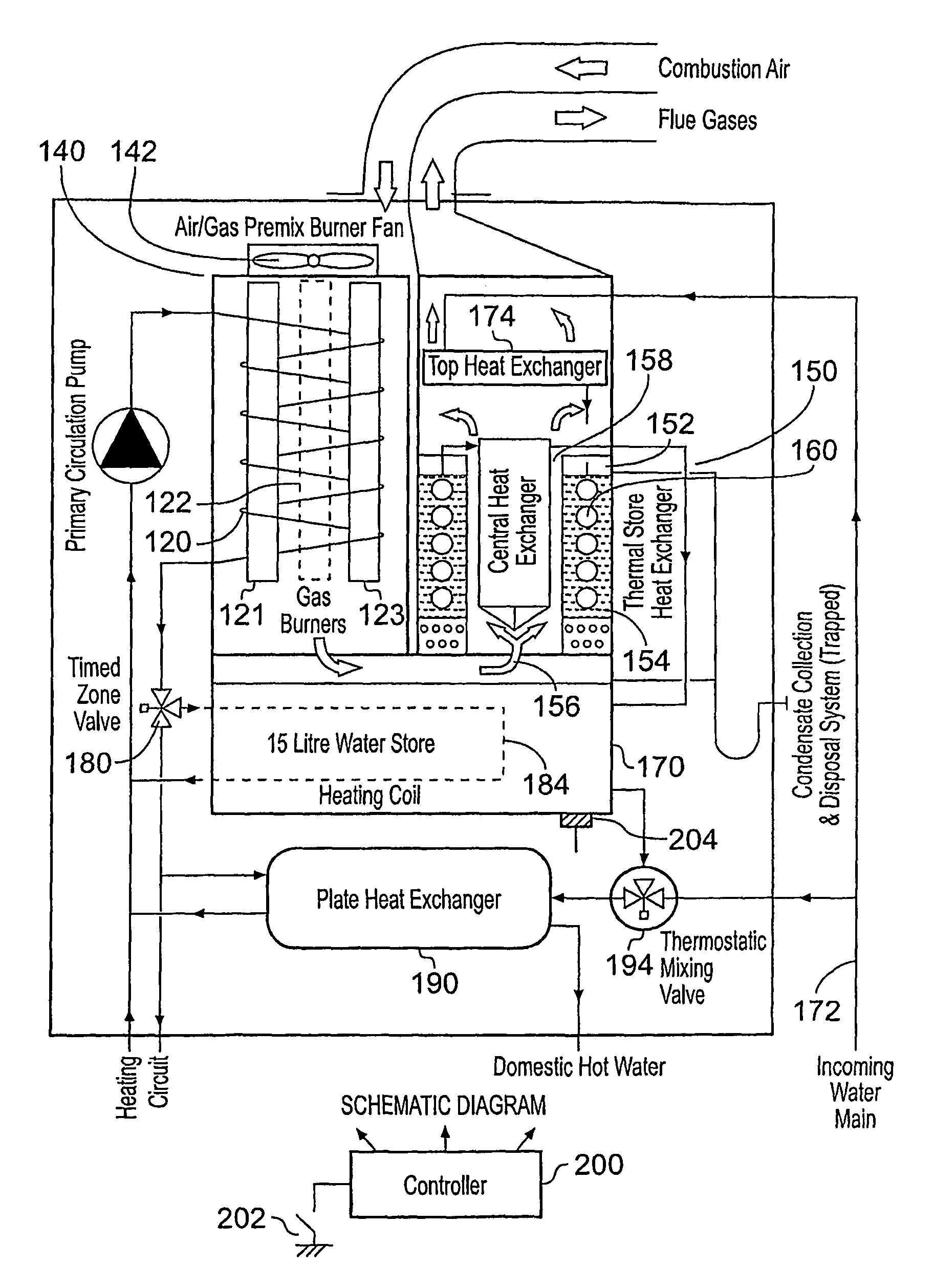

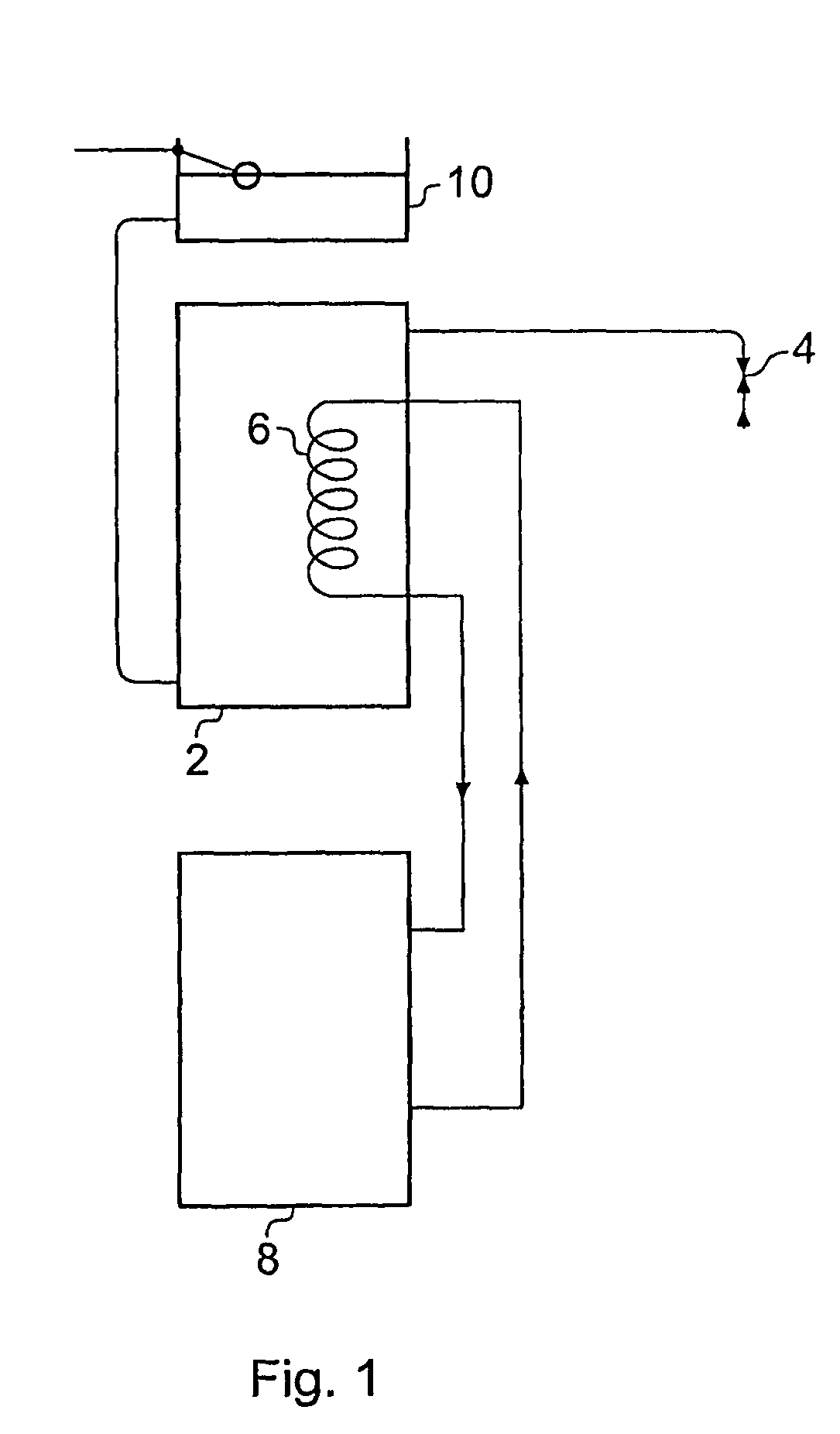

Heating system

InactiveUS8910880B2Speed up heat transferVarying amountSolar heating energySpace heating and ventilation detailsPlate heat exchangerEngineering

A heating system comprising a fuel burner in co-operation with a primary heat exchanger, a reservoir for storing warmed water in, and a blending valve, and a controller wherein in use a user can signal to the controller to warm the water in the water store using a heater or by the primary heat exchanger, and when hot water is required water is removed from the water store and mixed with water from a cold main prior to being or after the water from the cold main has been admitted to a further heat exchanger for heating the water.

Owner:CANETIS HLDG LTD

System and method for protecting the privacy and security of stored biometric data

A data storage system that protects privacy and ensures security includes a plurality of nodes in a networked architecture, the nodes being adapted to securely communicate and co-operate with one another to allow storage and retrieval of data. A single piece of biometric data is associated only with a blinded identifier and securely divided across one or more nodes, adapted for data storage. The data itself and the link to the original individual, from whom the biometric was acquired, cannot be obtained without the co-operation of two or more nodes.

Owner:DAON TECH

Compressor Unit

InactiveUS20090263265A1Reduce complexityEnhanced interactionRotary piston pumpsMechanical energy handlingRotational axisEngineering

The invention relates to a compressor unit, in particular for underwater operations, comprising a compressor with a rotational axis and an electric motor. Said compressor unit has a housing with an automation unit for control and regulation tasks. The aim of the invention is to improve the co-operation of the automation unit and the compressor unit and in particular to reduce the complexity of the cooling of the automation unit and signal and energy transmission. To achieve this, an additional housing, which contains the automation unit, is attached to the housing.

Owner:SIEMENS AG

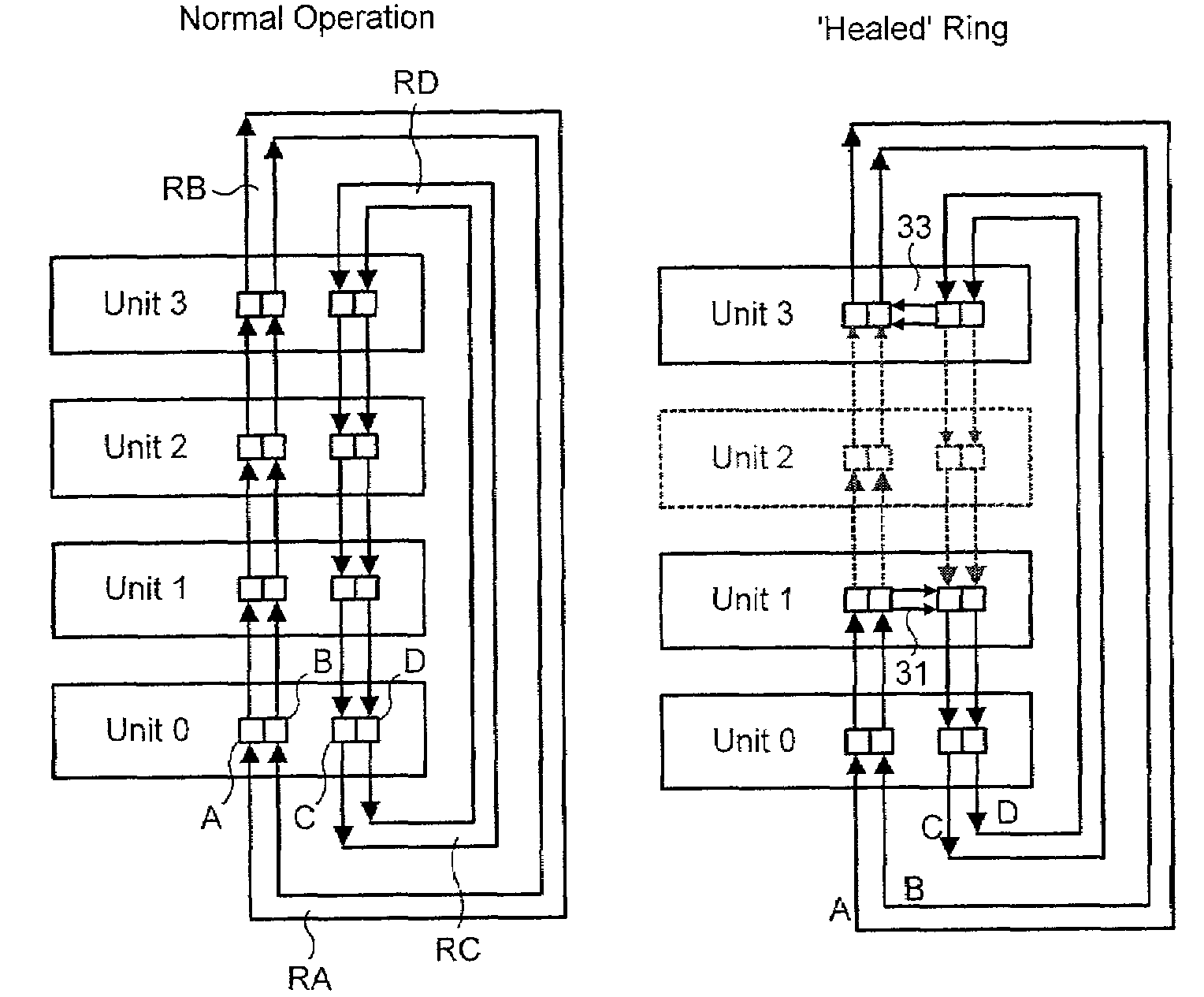

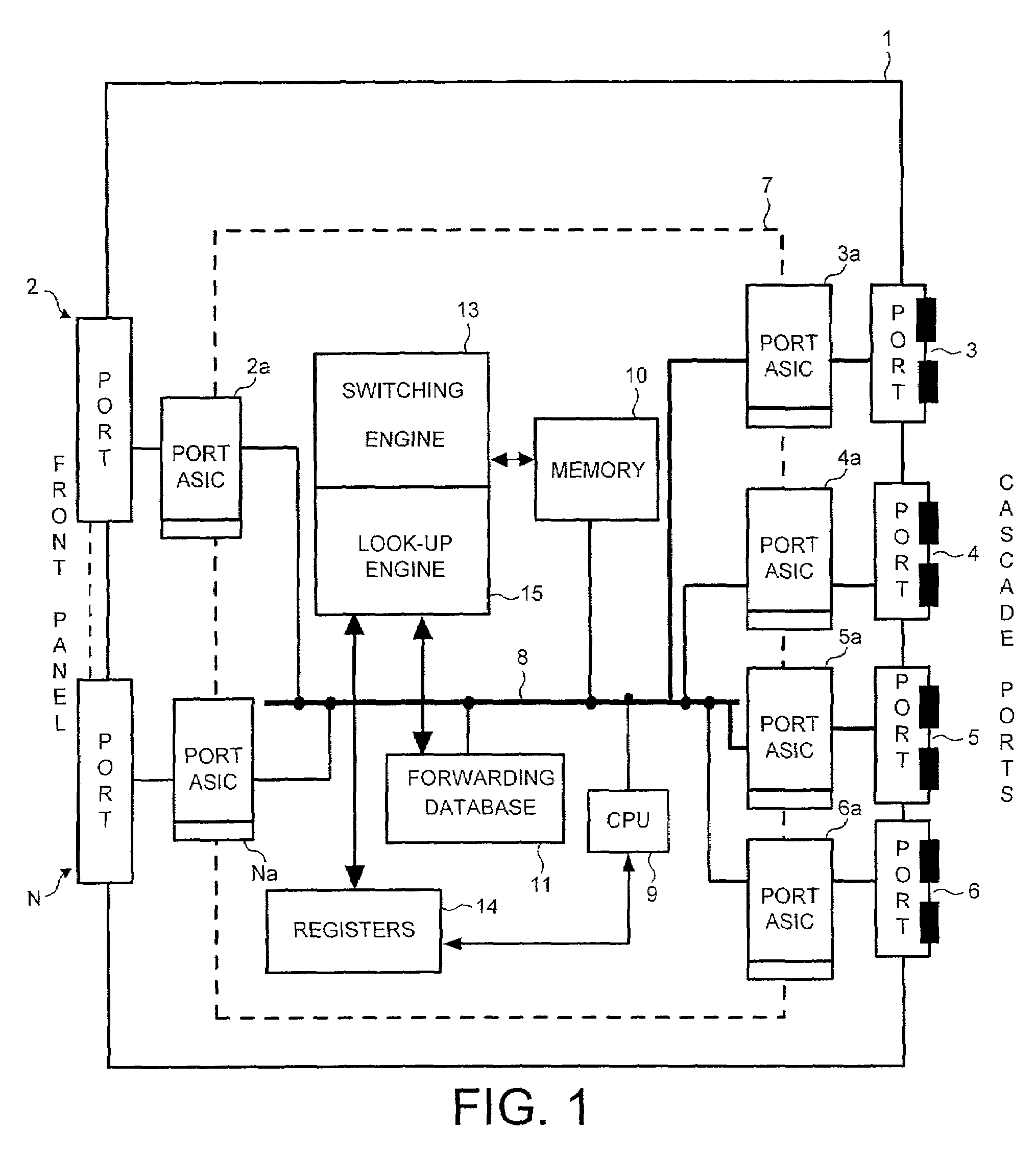

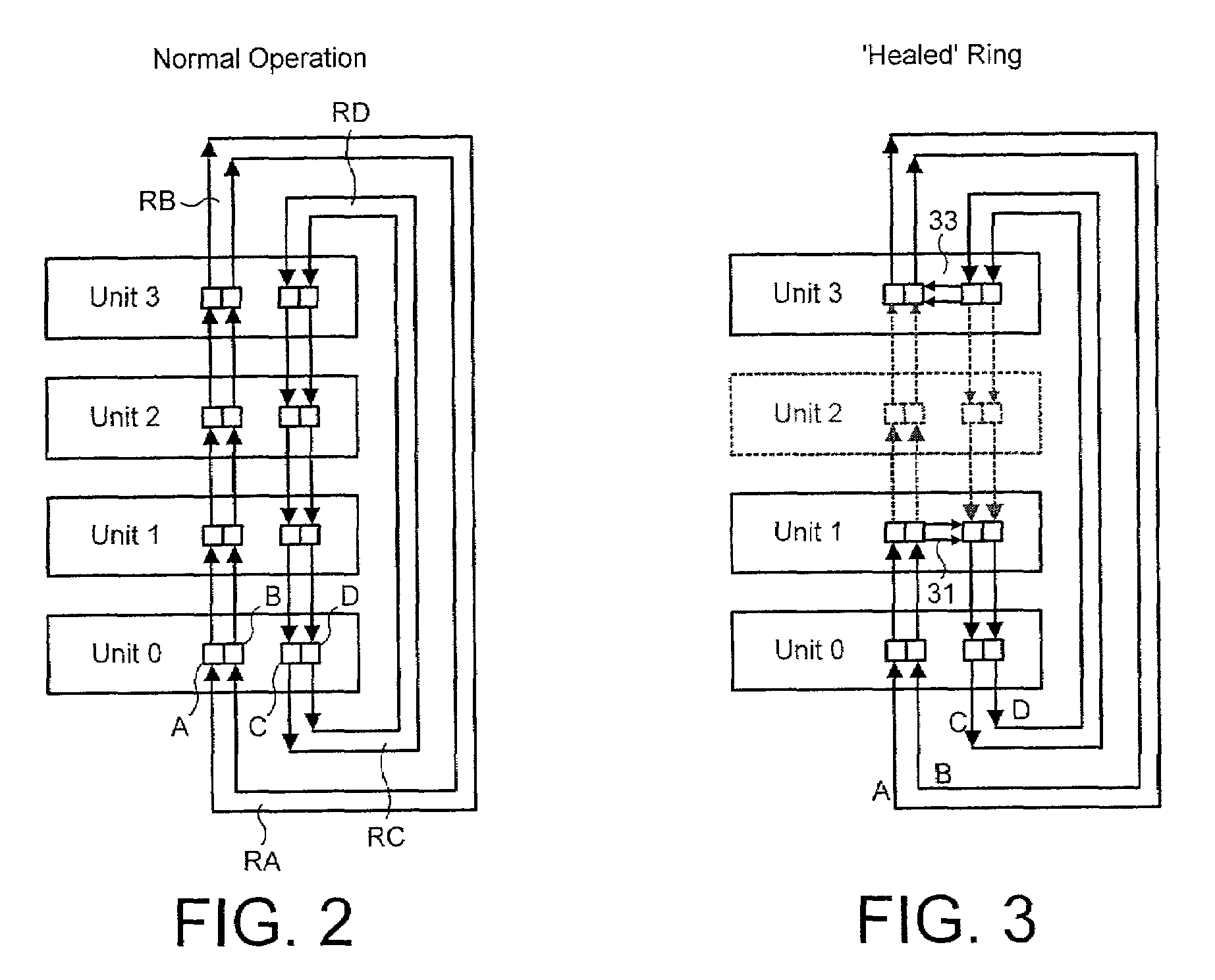

Cascade system for network units

Network units such as switches for use in a cascaded stack are organised to provide a cascade connection in the form of a dual unidirectional connection so that, in its ordinary configuration, there is at least one and preferably more than one unidirectional ring for each direction around the cascade, each ring including a respective port on each unit. For each ring, each port on a unit is connected by a respective link to a corresponding port on the preceding unit and the following unit. The units provide a self-healing operation in the event of various kinds of operational failure. The self-healing operation includes loop-back of packets in units adjacent the failure and bypass of a packet switching process for other units. The units include control logic for passing control frames containing status information relating to the units and links between them and for co-operation with a CPU to control a switching engine to perform the self-healing operation in accordance with that status information. The units forward on the cascade packets with headers that identify a destination port and the unit on which that port is located and also indicate which units have and have not been traversed by a packet.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

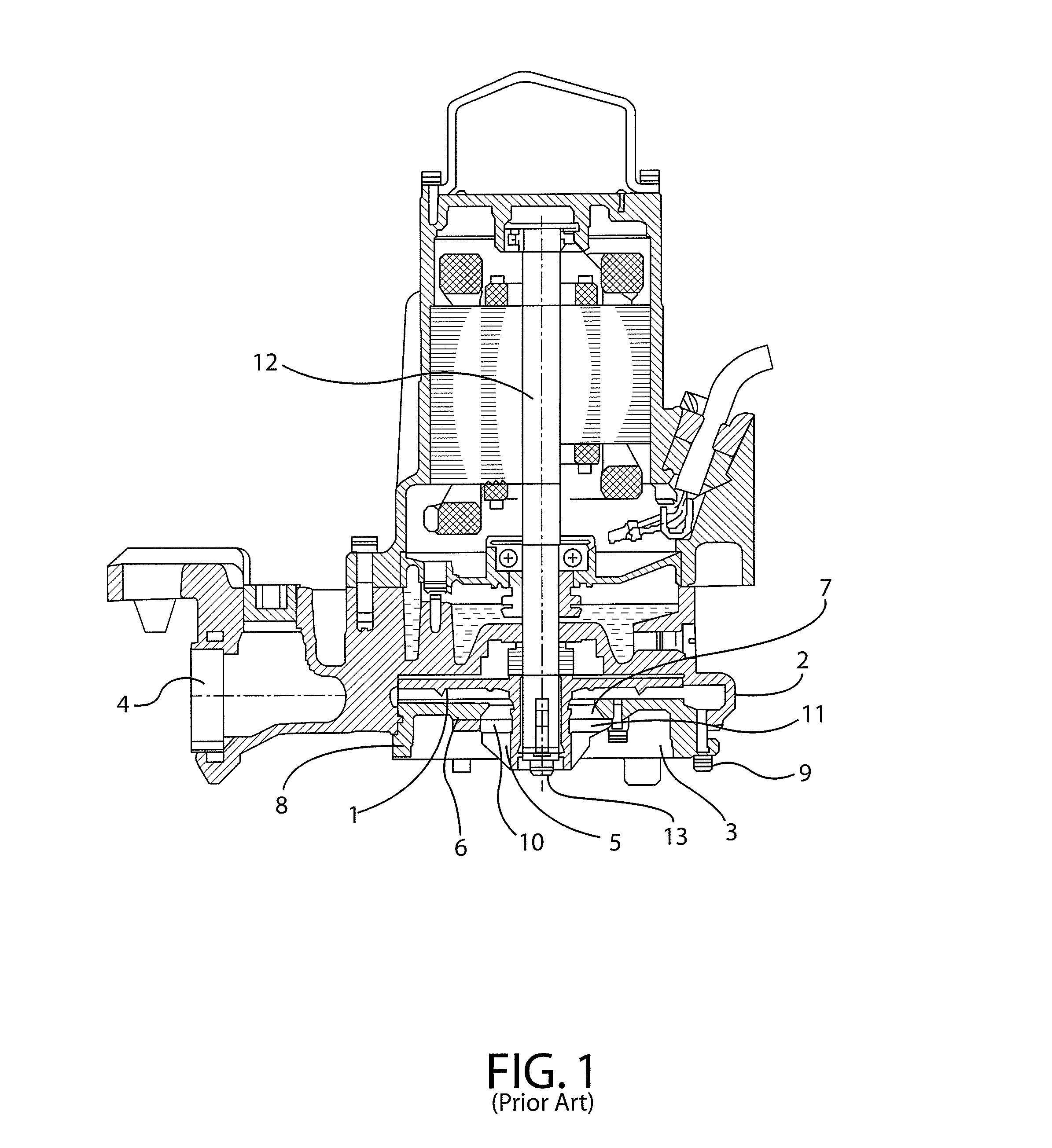

Pump assembly and method

ActiveUS8366384B2Eliminate riskEfficient cuttingSpecific fluid pumpsPump componentsDrive shaftEngineering

Owner:XYLEM IP HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com