Compressor Unit

a compressor unit and compressor technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of introduction of heat into the pump flow, and it is virtually impossible to use seawater as a cooling medium, so as to reduce the complexity of cooling and improve the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

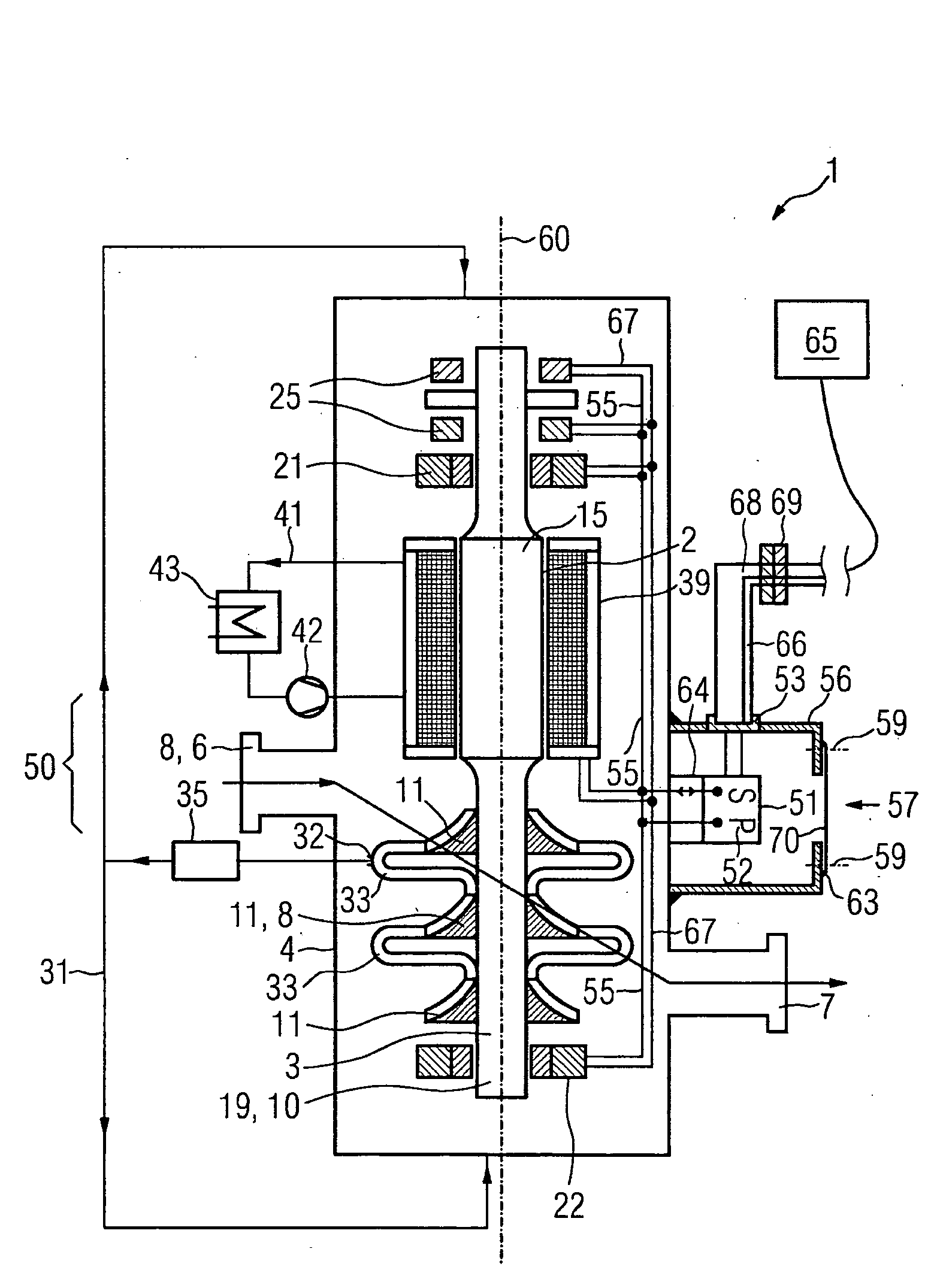

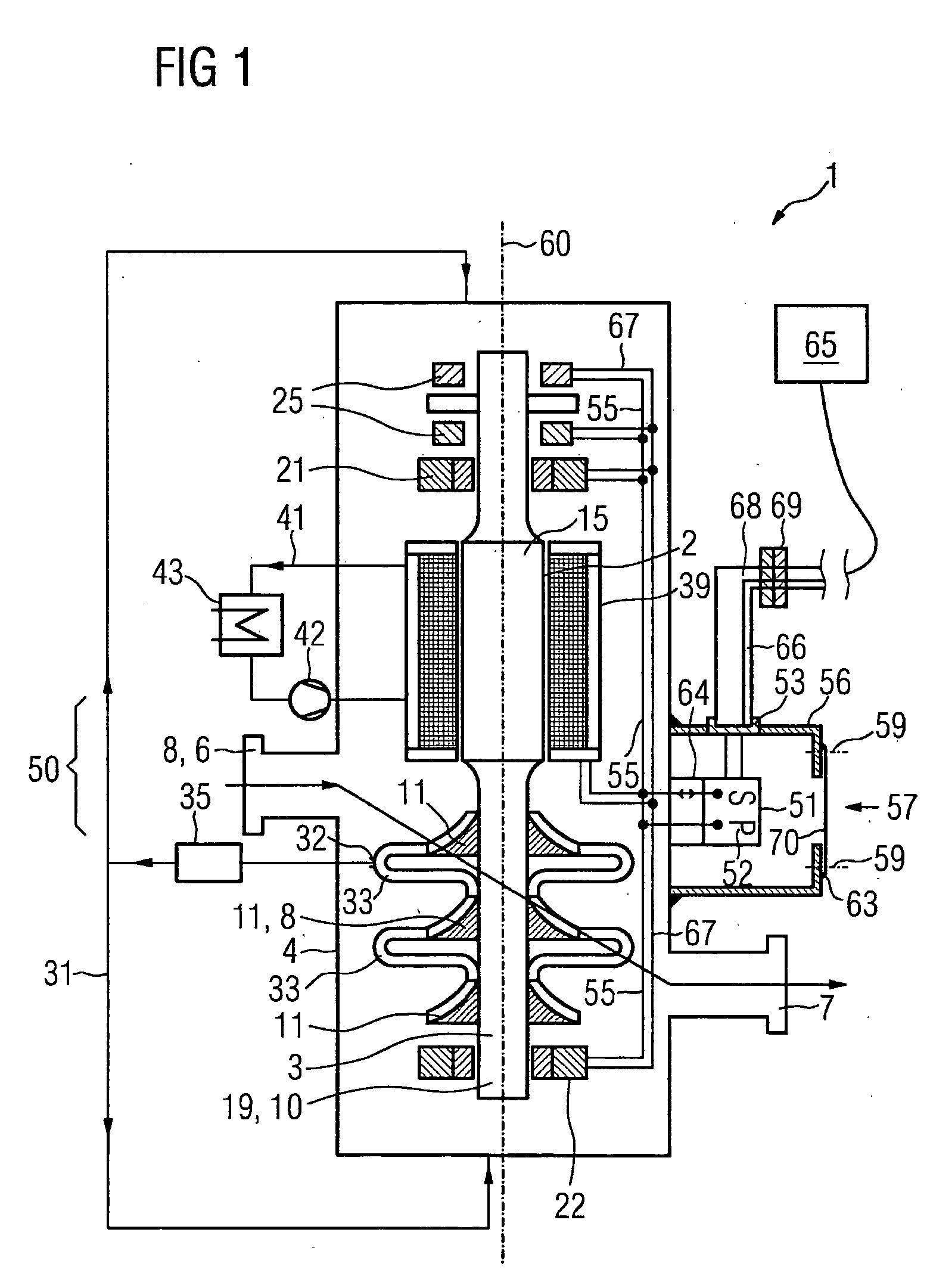

[0019]FIG. 1 shows a section along a compressor unit 1 according to the invention which has, as major components, a motor 2 and a compressor 3 in a housing 4 which is designed to be gas-tight. The housing 4 accommodates the motor 2 and the compressor 3. In the area of the junction between the motor 2 and the compressor 3, the housing 4 is provided with an inlet 6 and an outlet 7, with the fluid to be compressed being sucked in through the inlet 6 by means of an intake connecting stub 8, and with the compressed fluid flowing out through the outlet 7.

[0020]The compressor unit 1 is arranged vertically during operation, with a motor rotor 15 of the motor 2 being combined via a compressor rotor 9 of the compressor 3 to form a common shaft 19, which rotates about a common vertical rotation axis 60.

[0021]The motor rotor 15 is mounted in a first radial bearing 21 at the upper end of the motor rotor 15.

[0022]The compressor rotor 9 is mounted in a second radial bearing 22 at a lower position....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com