Circular section spring mechanism with adjustable rigidity

A spring mechanism, circular section technology, applied in springs/shock absorbers, coil springs, mechanical equipment, etc., can solve the problems of long debugging time, inability to meet, and high environmental requirements, saving debugging time, reducing production costs, The effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

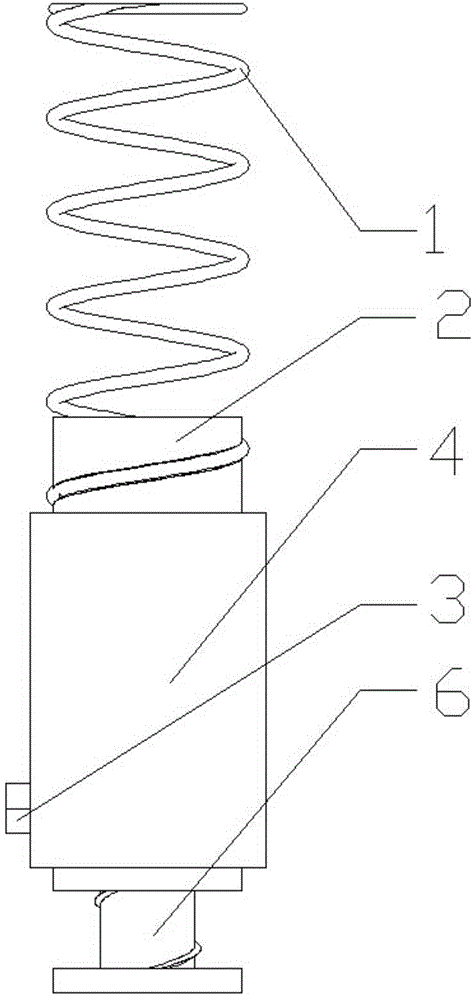

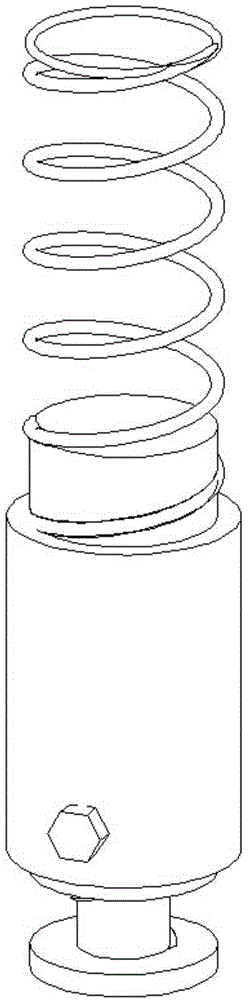

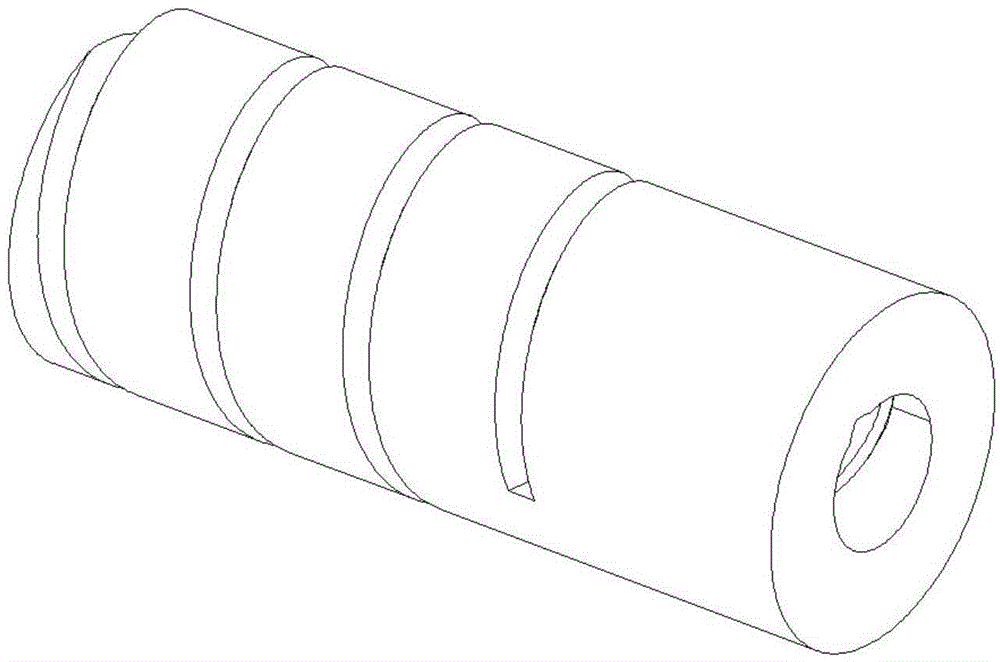

[0021] A circular section spring mechanism with adjustable stiffness, comprising a tube body 2, a circular section spring 1, a sleeve 4, a fastening screw 3 and an adjusting screw 6, the outer wall of the tube body 2 is provided with external threads, and the inner wall of the tube body 2 is provided with There is an internal thread, the adjusting screw 6 is screwed into the internal thread to form the first helical pair, the circular section spring 1 is screwed into the pipe body 2 to form the second helical pair, the pipe sleeve 4 is set outside the pipe body 2, and the pipe sleeve 4 is provided with threaded holes 5. The fastening screw 3 is installed in the threaded hole 5 .

[0022] The circular section spring 1 is a cylindrical equi-pitch helical spring.

[0023] The pitches of the internal thread and the external thread are equal.

[0024] The lead angles of the internal and external threads of the pipe body 2 are smaller than the minimum equivalent friction angle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com