Automatic feeding system and method

A technology of automatic feeding and material level, applied in the field of feeding system, can solve the problems of no online linearity, only regular feeding, affecting production, etc., to ensure product quality, reduce labor intensity of workers, and improve the level of production automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

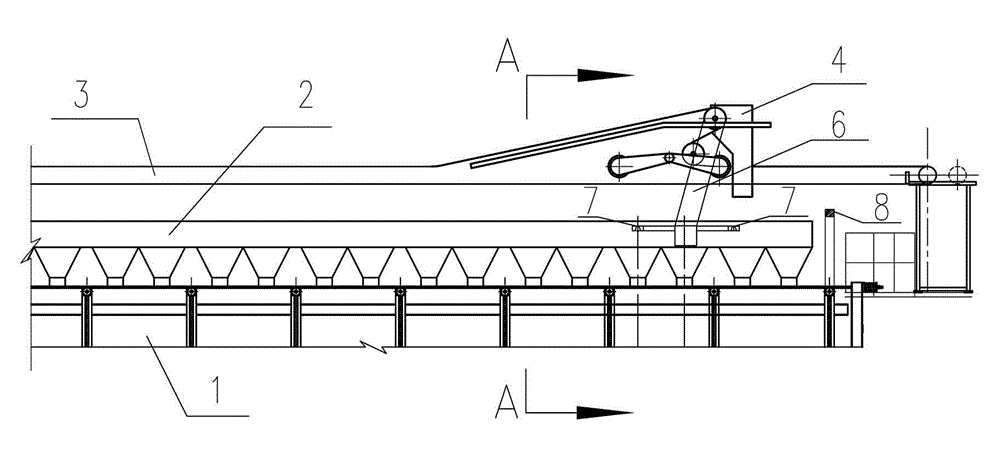

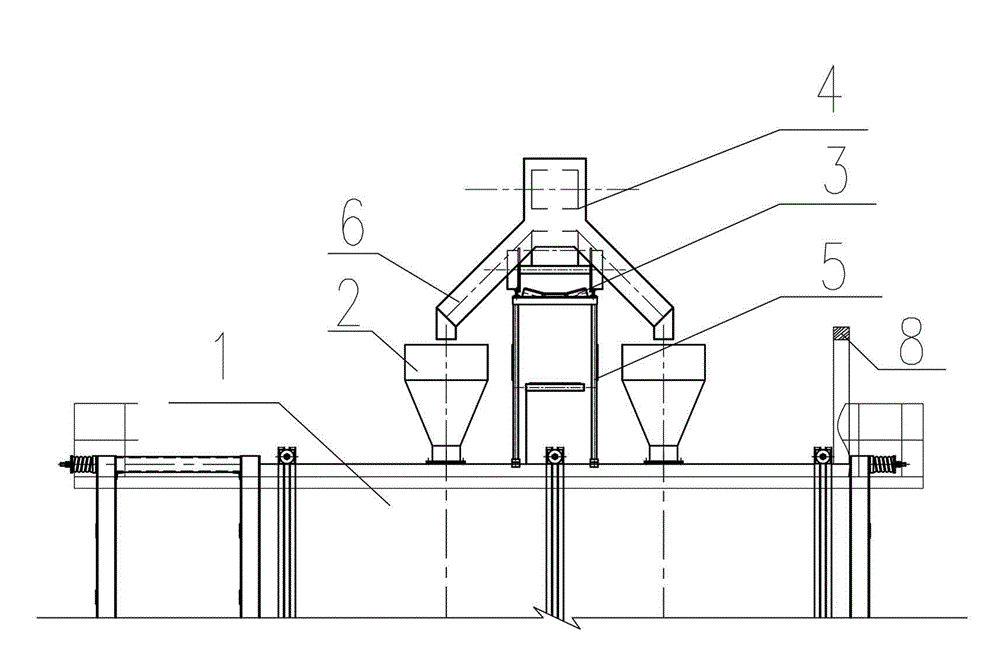

[0019] As shown in the figure, the automatic feeding system of the present invention includes two rows of pot calciners 1, a receiving hopper 2 above each pot calcining furnace 1, and a supporting steel structure 5 between the two rows of receiving hoppers 2, A belt 3 is provided above the supporting steel structure 5, and a moving unloading trolley 4 is arranged above the belt 3. The discharge passages on both sides of the unloading trolley 4 communicate with the upper end of the unloading chute 6 respectively. The lower end is located above the receiving hopper 2 . The supporting steel structure 5 stands on the roof of the pot calciner 1 . The unloading trolley 4 is located on the rail, and the rail is installed on the supporting steel structure 5 . The unloadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com