Non-horizontal rail car body leveling process

A non-horizontal, vehicle-body technology, applied in the direction of measuring devices, instruments, surveying, mapping and navigation, etc., can solve the problem of leveling benchmarks without a vehicle body, and achieve the effect of low work intensity, high work precision, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

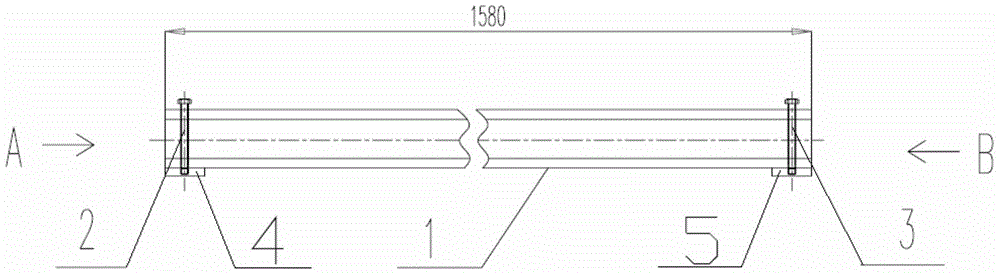

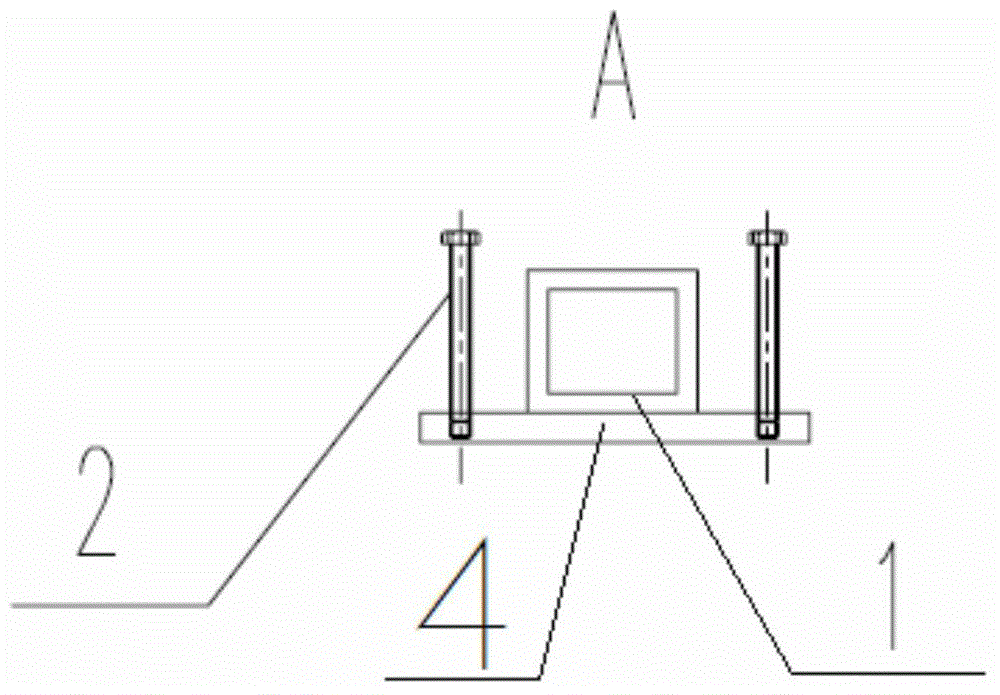

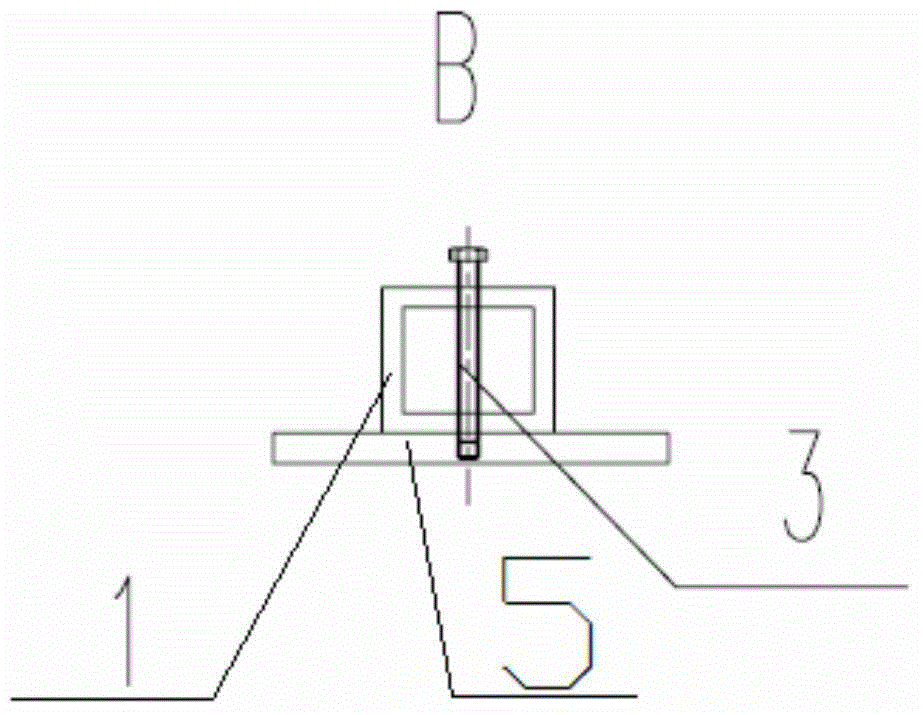

[0023] Such as figure 1 , figure 2 , image 3 As shown, the non-horizontal rail car body leveling device used in the leveling process of this embodiment includes square steel 1, and the flatness of the upper plane of square steel 1 is not more than 0.3mm; The first reference block 4 and the second reference block 5 are arranged, and the reference block is welded and fixed on the lower surface of both ends of the square steel 1 . The flatness of the lower plane of the reference block is not greater than 0.3mm, wherein two levelness adjustment bolts 2 are vertically arranged symmetrically on the first reference block 4 at the first end of the square steel, and one is vertically arranged at the second end of the square steel 1. The height difference adjusting bolt 3 at the lateral center position of the square steel 1. The first reference block 4 at the first end of the square steel 1 is provided with 2 screw holes, and the levelness adjusting bolt 2 is screwed into the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com