In-fiber optical whispering gallery microcavity structure and its manufacturing method

A kind of whispering gallery, optical technology, applied in manufacturing tools, laser welding equipment, coupling of optical waveguides, etc., can solve the problem of difficult to achieve miniaturization, integration, low system compactness and stability, complex microsphere filling process The problem is to reduce the difficulty of positioning, accurately adjust the size parameters, and simplify the processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

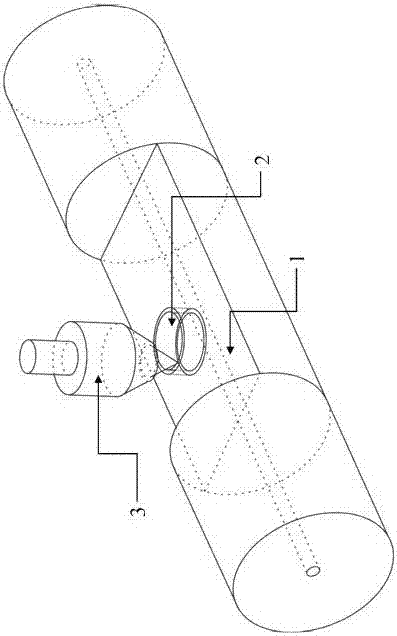

[0018] A fiber-type optical whispering gallery microcavity structure, including an optical fiber, its innovation lies in: an annular groove is arranged on the outer side of the fiber core on the optical fiber, the axial direction of the annular groove is parallel to the radial direction of the optical fiber, and the outer wall of the annular groove is parallel to the optical fiber. Spaces are left between the outer walls of the fiber core, and the depth of the annular groove covers the fiber core of the optical fiber, and the annular groove forms an optical whispering gallery microcavity.

[0019] A method for manufacturing a fiber-shaped optical whispering gallery microcavity structure, the innovation of which is: fabricating a fiber-shaped optical whispering gallery microcavity structure according to the following method:

[0020] 1) Use a femtosecond laser to cut the surface of the optical fiber, and cut a processed surface outside the core of the optical fiber. The processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com