A kind of 5g metal/ceramic composite circuit board and preparation method thereof

A ceramic composite and circuit board technology, which is applied in the direction of circuit substrate materials, printed circuits, printed circuit components, etc., can solve the problems of low bonding strength between copper and ceramics, low yield of laser drilling, and immature drilling technology, etc. , to achieve the effect of being suitable for large-scale industrial production, excellent solderability, and easy control of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a 5G metal / ceramic composite circuit board, and the specific preparation process is as follows.

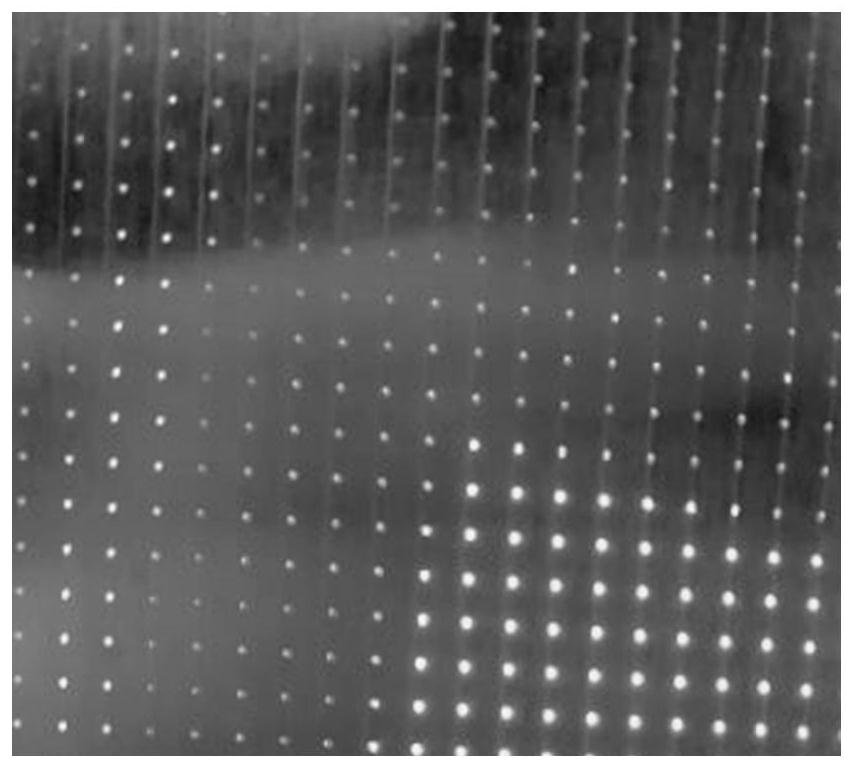

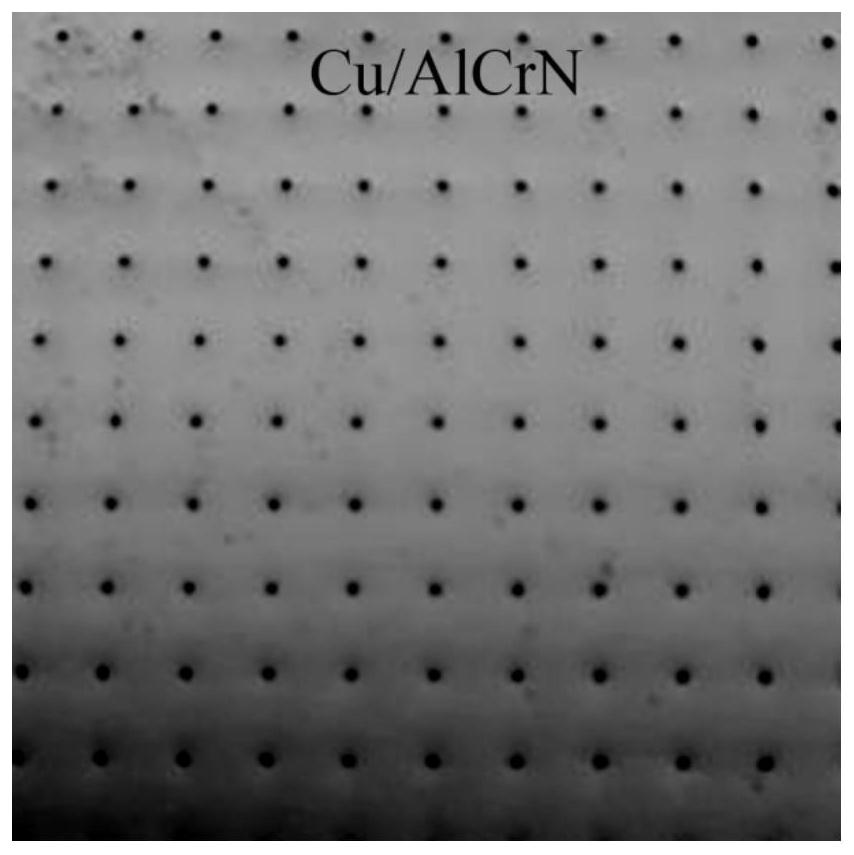

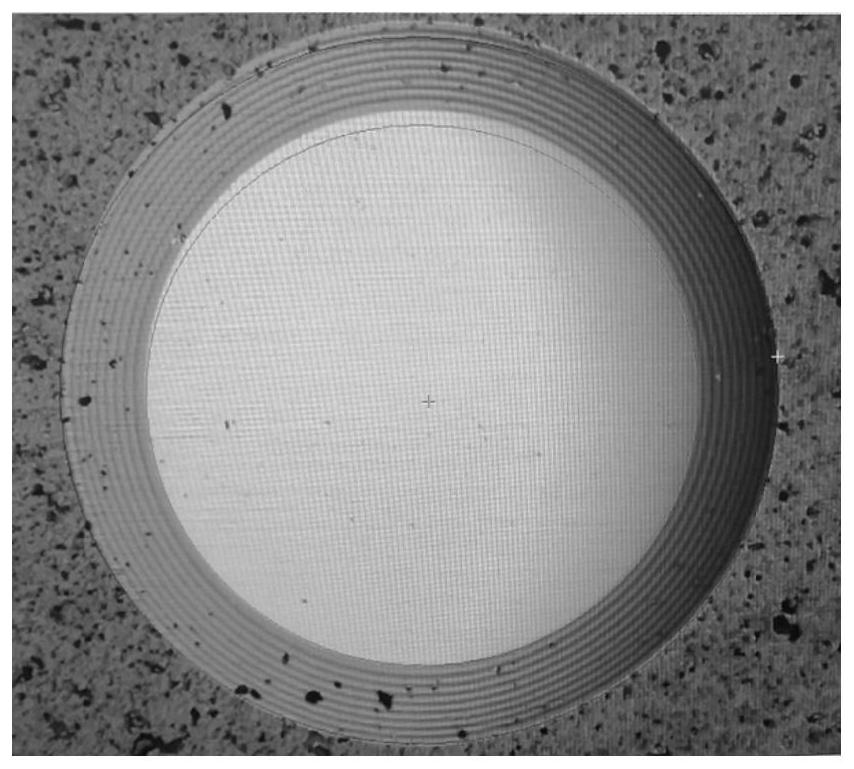

[0043] The 0.3mm thick Al plate purchased in the market is processed on the surface, and a high-density hole array with a diameter of 0.3mm is drilled on its surface (such as figure 1 ), then cleaned, dried, and placed on the multi-target co-deposition preparation platform; adjust the target as needed, for example: copper target and AlCr target, the two targets are arranged alternately (such as Image 6 ); Turn on the mechanical pump and the molecular pump to pump the background vacuum of the vacuum chamber to less than 5.0×10 -3 Pa, feed Ar gas and control the flow rate at 100 sccm, the air pressure is less than 0.2 Pa, the sample temperature is 420 ° C, the negative bias voltage is 300 V, and the bombardment time is 10 min. Turn on the turret and Cu target, keep the sample bias at -80V, keep the sample temperature at 420°C, target current at 120A...

Embodiment 2

[0045] This embodiment provides a 5G metal / ceramic composite circuit board, and the specific preparation process is as follows.

[0046] The 0.3mm thick Al plate purchased in the market is processed on the surface, and a high-density hole array with a diameter of 0.3mm is drilled on its surface (such as figure 1), and then cleaned, dried, and placed on the multi-target co-deposition preparation platform; adjust the target as needed, for example: copper target and Al target, the two targets are arranged alternately; turn on the mechanical pump and molecular pump to reduce the background of the vacuum chamber Vacuum to less than 5.0×10 -3 Pa, feed Ar gas and control the flow rate at 100 sccm, the air pressure is less than 0.2 Pa, the sample temperature is 420 ° C, the negative bias voltage is 300 V, and the bombardment time is 10 min. Turn on the turret and Cu target, keep the sample bias at -80V, keep the sample temperature at 420°C, target current at 120A, deposit for 5min, a...

Embodiment 3

[0048] This embodiment provides a 5G metal / ceramic composite circuit board, and the specific preparation process is as follows.

[0049] The 0.3mm thick Al plate purchased in the market is processed on the surface, and a high-density hole array with a diameter of 0.35mm is drilled on its surface (such as Figure 4 ), and then cleaned, dried, and placed on the multi-target co-deposition preparation platform; adjust the target as needed, for example: copper target and Cr target, the two targets are arranged alternately; turn on the mechanical pump and molecular pump to reduce the background of the vacuum chamber Vacuum to less than 5.0×10 -3 Pa, feed Ar gas and control the flow rate at 100 sccm, the air pressure is less than 0.2 Pa, the sample temperature is 420 ° C, the negative bias voltage is 300 V, and the bombardment time is 10 min. Turn on the turret and Cu target, keep the sample bias at -80V, keep the sample temperature at 420°C, target current at 120A, deposit for 5min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com