A method of component change control

A technology for change control and parts, applied in parts change control, complex mechanical design and manufacturing, to simplify the change control process, improve product development quality, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

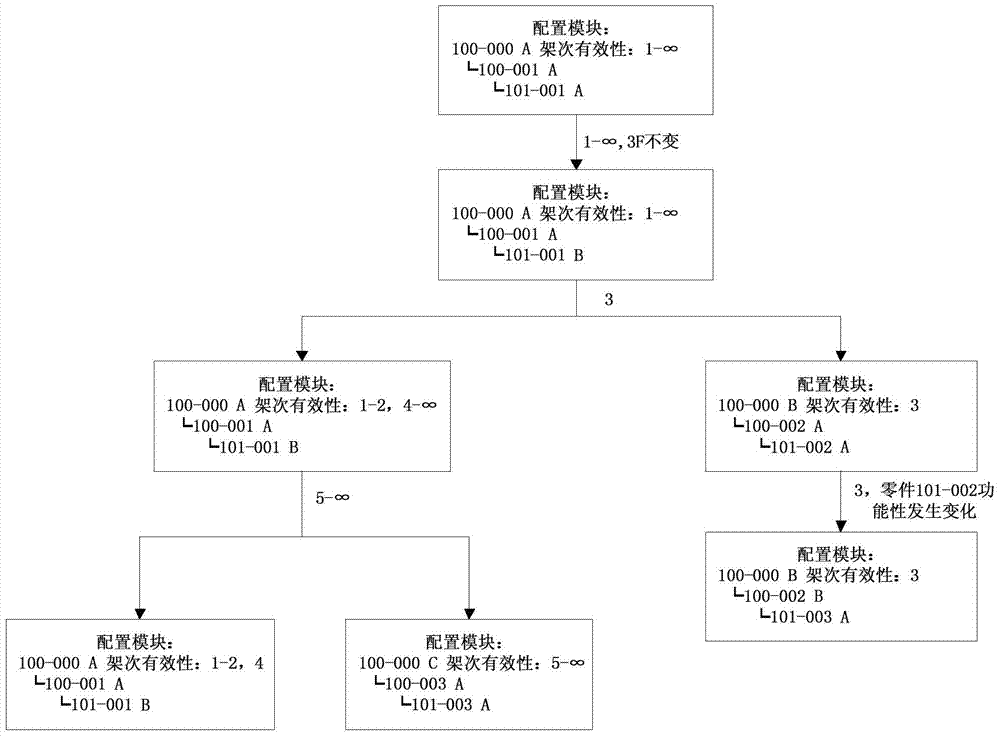

Examples

Embodiment Construction

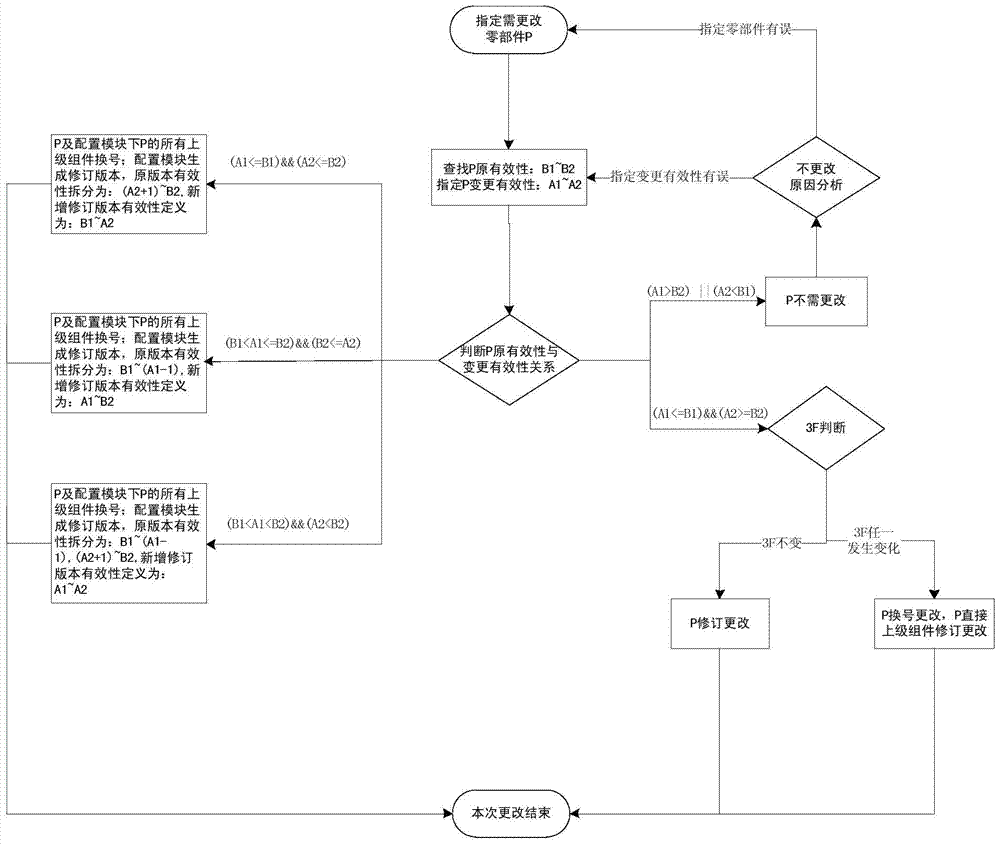

[0030] Principle of the present invention: a method for controlling part change, the method may further comprise the steps:

[0031] 1) If it is judged that a component under the product configuration module needs to be changed, then designate the component as the component to be changed;

[0032] 2) Find the original validity range of the parts to be changed from B1 to B2, and specify the validity range of the change order of the parts as A1 to A2, where A1, A2, B1, and B2 are positive integers, and A1≤A2, B1≤B2 ;

[0033] 3) Judging the relationship between the original validity range of parts that need to be changed and the validity range of the modified sortie:

[0034] a) If A1=B2, judge the assembly, function and interchangeability of the parts to be changed: if the assembly, function and interchangeability remain unchanged, generate a revised version of the parts to be changed; if If any of the assembly, function and interchangeability has changed, the part number tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com