Motor quick repair wire removal tool

A fast and tool technology, used in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve problems such as low efficiency, troublesome motor maintenance, waste of time and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

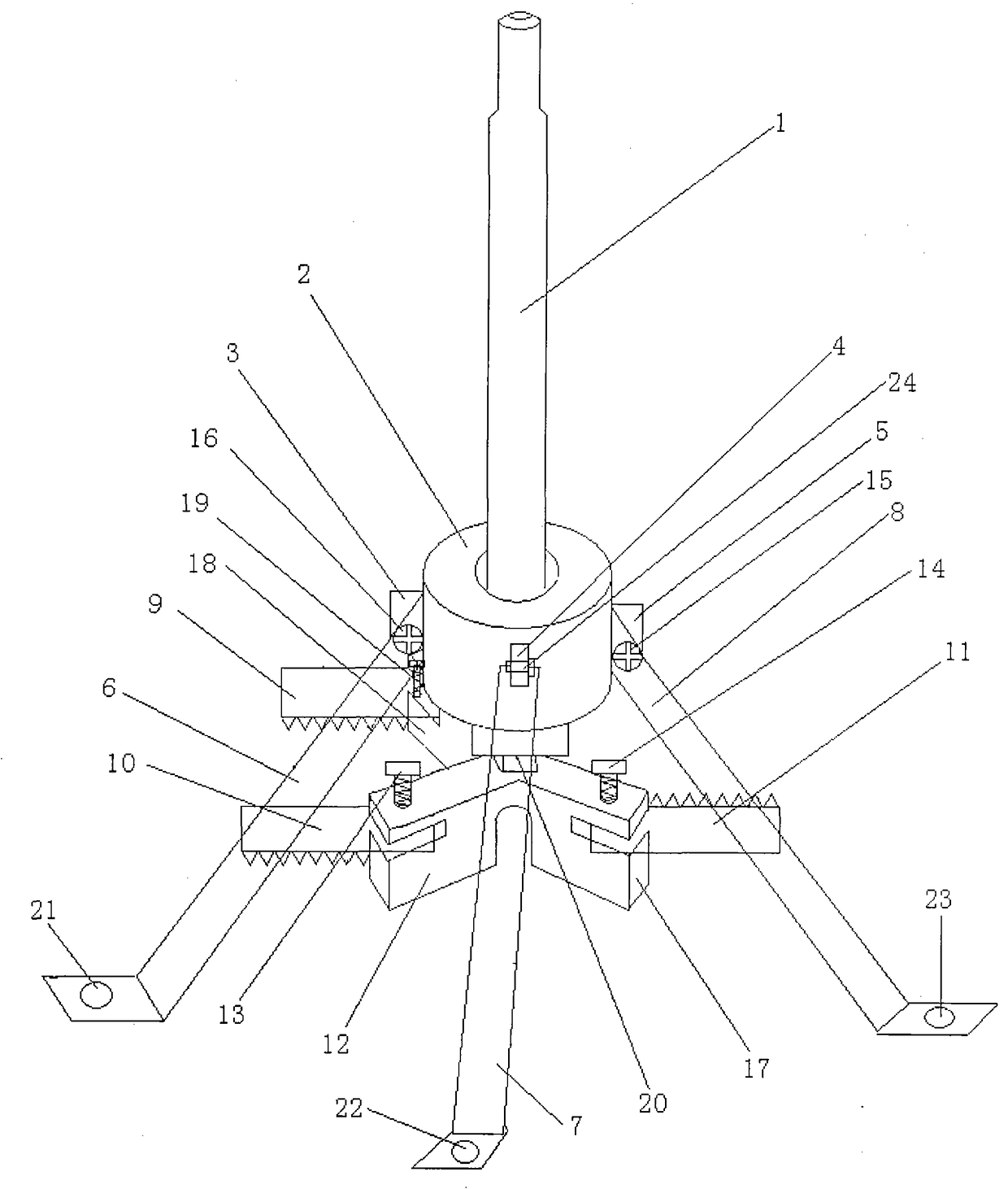

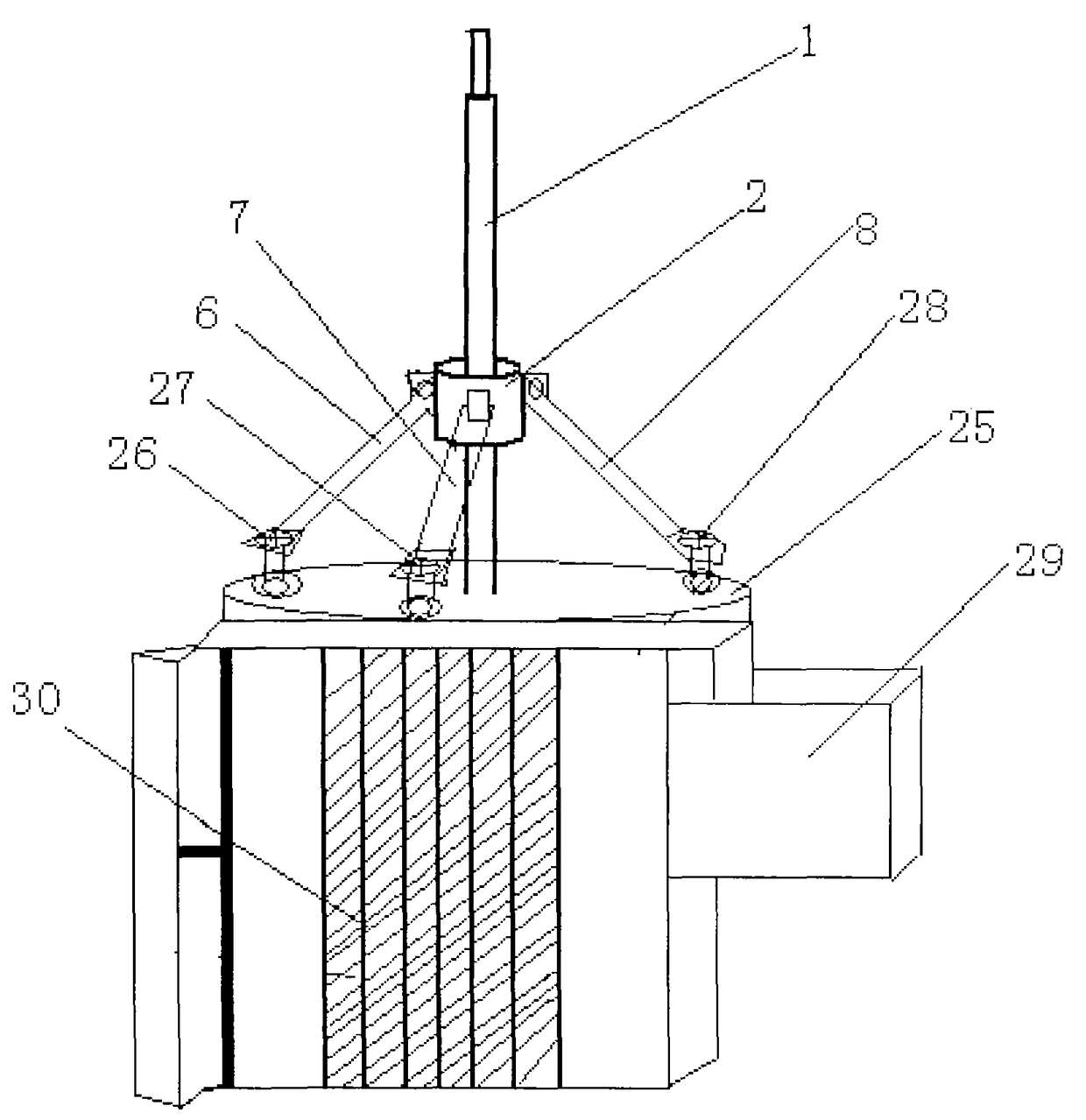

[0010] exist figure 1 and figure 2 In the shown embodiment, drill bit (1), movable round block (2), left ear frame (3), middle ear frame (4), right ear frame (5), left bracket (6), middle bracket ( 7), right bracket (8), left saw blade (9), middle saw blade (10), right saw blade (11), middle groove iron (12), middle support head screw (13), right support head screw (14), right fixing screw (15), left fixing screw (16), right grooved iron (17), left grooved iron (18), left supporting head screw (19), connection block (20), left bracket Hole (21), middle bracket hole (22), right bracket hole (23), middle fixing screw (24), motor housing (25), left screw (26), middle screw (27), right screw (28) , wire box (29), motor seat (30).

[0011] Implement the quick maintenance and disassembly tool of the motor of the present invention, the drill bit (1) is covered with a movable round block (2), the left side of the movable round block (2) is fixed to the left ear frame (3), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com