Liquid sweetener composition

A sweetener and composition technology, applied in the fields of food science, application, food preparation, etc., can solve the problems of increasing the supply of high fructose syrup, difficult to supply high fructose syrup stably, etc., and achieves price reduction, stable supply, and reduced use. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

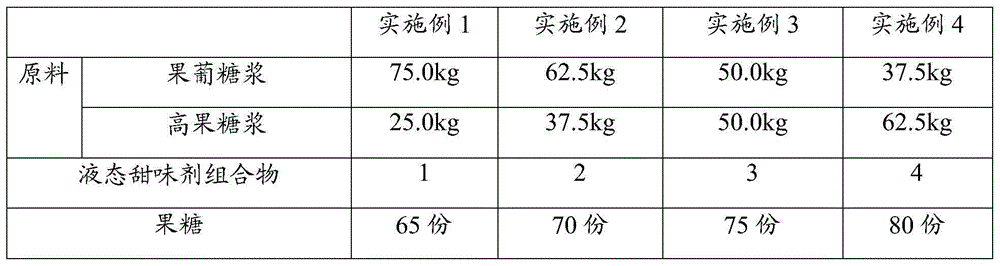

Embodiment 1

[0042] Stirring and mixing 75.0kg fructose syrup (manufactured by Japan Corn Starch Co., Ltd., HFM-75, water content 24.5%) and 25.0kg high fructose syrup (manufactured by Japan Corn Starch Co., Ltd., HFS-95, water content 24.5%), produced Liquid sweetener composition 1.

Embodiment 2

[0044] Stir and mix 62.5kg fructose syrup (manufactured by Japan Corn Starch Co., Ltd., HFM-75, water content 24.5%) and 37.5kg high fructose syrup (manufacture by Japan Corn Starch Co., Ltd., HFS-95, water content 24.5%), produce Liquid sweetener composition 2.

Embodiment 3

[0046] Stirring and mixing 50.0kg fructose syrup (manufactured by Japan Corn Starch Co., Ltd., HFM-75, water content 24.5%) and 50.0 kg high fructose syrup (manufactured by Japan Corn Starch Co., Ltd., HFS-95, water content 24.5%), produced Liquid Sweetener Composition3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com