Method for separating protein from corn puree

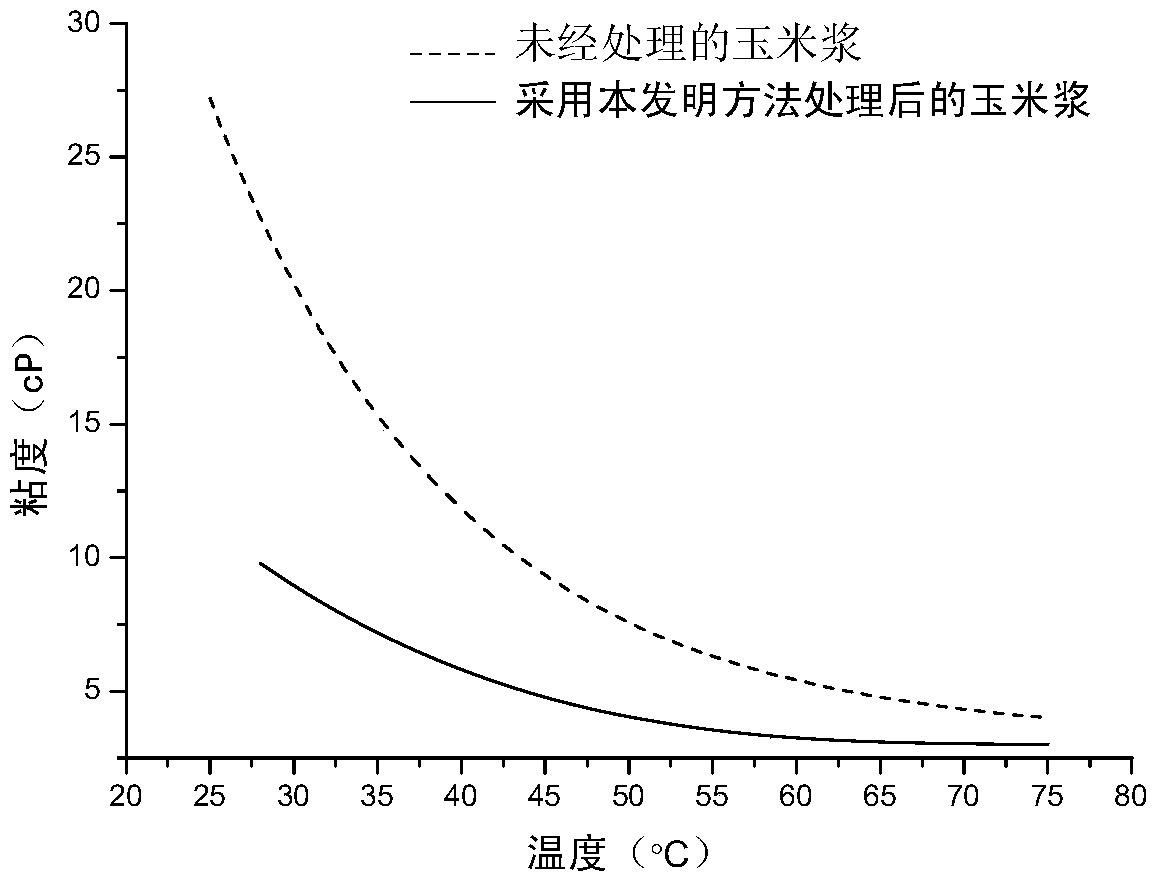

A technology for separating protein and corn steep liquor is applied in the field of protein separation from corn puree, which can solve the problems of increasing production cost, large consumption of reagents and high corn steep liquor yield, and achieves the effects of increasing production load and improving separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

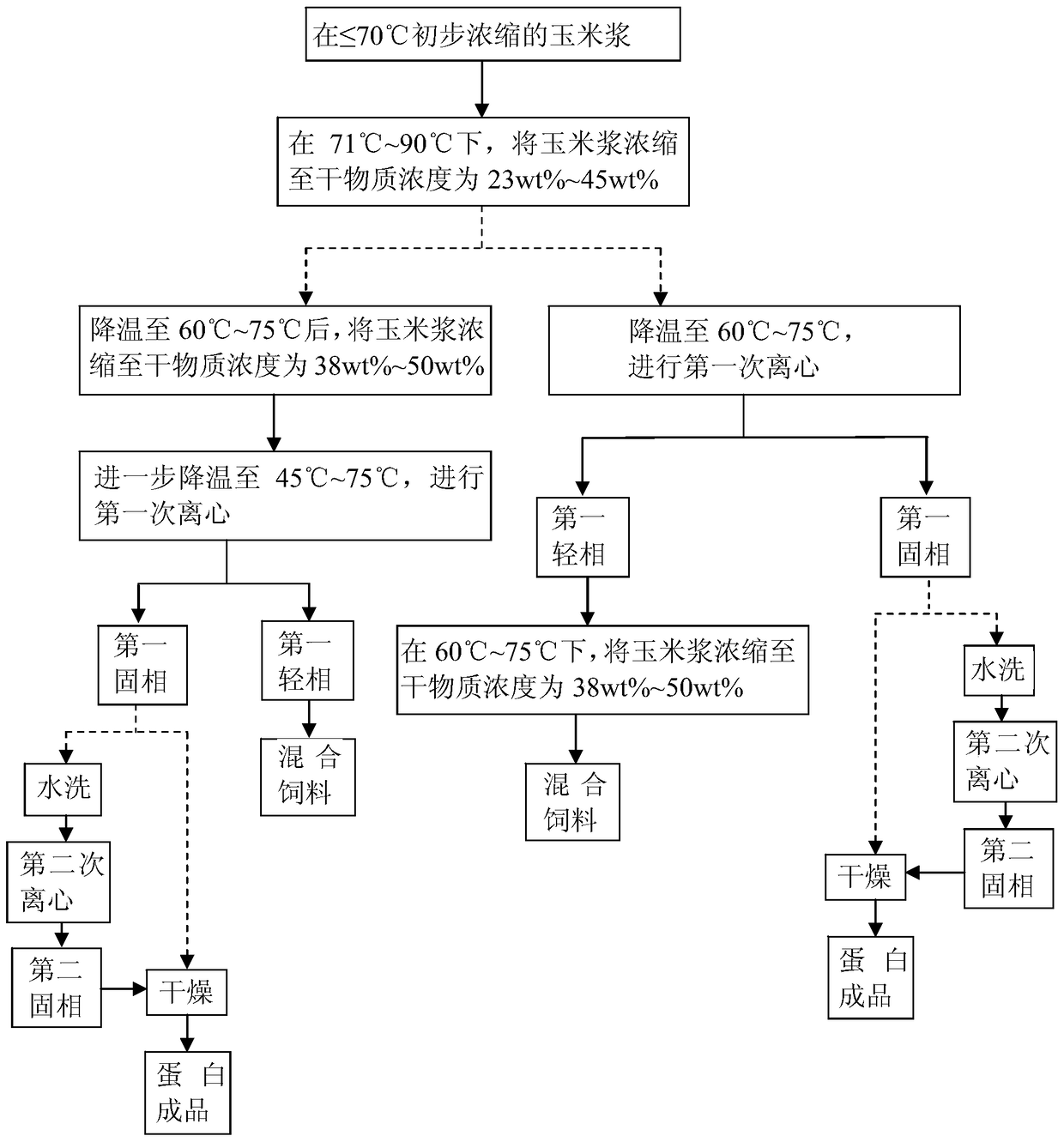

Method used

Image

Examples

Embodiment 1

[0067] A five-effect evaporation system (JMZ falling film evaporator, North Yida Energy Saving Equipment Co., Ltd.) is used to pass the corn puree through the fifth effect evaporator (evaporation temperature 55°C) and the fourth effect evaporator (evaporation temperature 65°C) Preliminary concentration is carried out to obtain a preliminary concentrated corn steep liquor (pH3.9) with a dry matter concentration of 18wt%, and pump it into the third effect evaporator, under the conditions of a vacuum of 0.055MPa and a temperature of 71°C , concentrating the pre-concentrated corn steep liquor to a dry matter concentration of 23 wt%, to obtain reconcentrated corn steep liquor.

[0068] Pump the re-concentrated corn steep liquor into the first effect evaporator and continue to evaporate until the dry matter concentration is 32wt%, and then pump it into the second effect evaporator to cool down to 66°C (vacuum degree 0.050MPa), and the cooled The corn steep liquor was further concent...

Embodiment 2

[0072] The five-effect evaporation system (JMZ falling film evaporator, North Yida Energy Saving Equipment Co., Ltd.) is used to pass the corn puree through the fifth-effect evaporator (evaporation temperature 56°C) and the fourth-effect evaporator (evaporation temperature 63°C). and the third-effect evaporator (evaporation temperature 70°C) for preliminary concentration to obtain a pre-concentrated corn steep liquor (pH3.6) with a dry matter concentration of 22wt%, and pump it into the first-effect evaporator for vacuum Under the conditions of a temperature of 0.061 MPa and a temperature of 90° C., the primary concentrated corn steep liquor was concentrated to a dry matter concentration of 45 wt % to obtain reconcentrated corn steep liquor. The re-concentrated corn steep liquor is pumped into the second effect evaporator and cooled to 75°C (vacuum degree 0.047MPa), and the cooled corn steep liquor is further concentrated to a dry matter concentration of 50wt% to obtain further...

Embodiment 3

[0077] The five-effect evaporation system (JMZ falling film evaporator, North Yida Energy Saving Equipment Co., Ltd.) is used to pass the corn puree through the fifth-effect evaporator (evaporation temperature 56°C) and the fourth-effect evaporator (evaporation temperature 62°C). and the third-effect evaporator (evaporation temperature 68°C) for preliminary concentration to obtain a preliminary concentrated corn steep liquor (pH3.8) with a dry matter concentration of 20%, and pump it into the first-effect evaporator for vacuum Under the conditions of a temperature of 0.058 MPa and a temperature of 85° C., the primary concentrated corn steep liquor was concentrated to a dry matter concentration of 31 wt % to obtain reconcentrated corn steep liquor. The re-concentrated corn steep liquor is pumped into the second effect evaporator and cooled to 60°C (vacuum degree 0.033MPa), and the cooled corn steep liquor is further concentrated to a dry matter concentration of 38wt% to obtain f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com