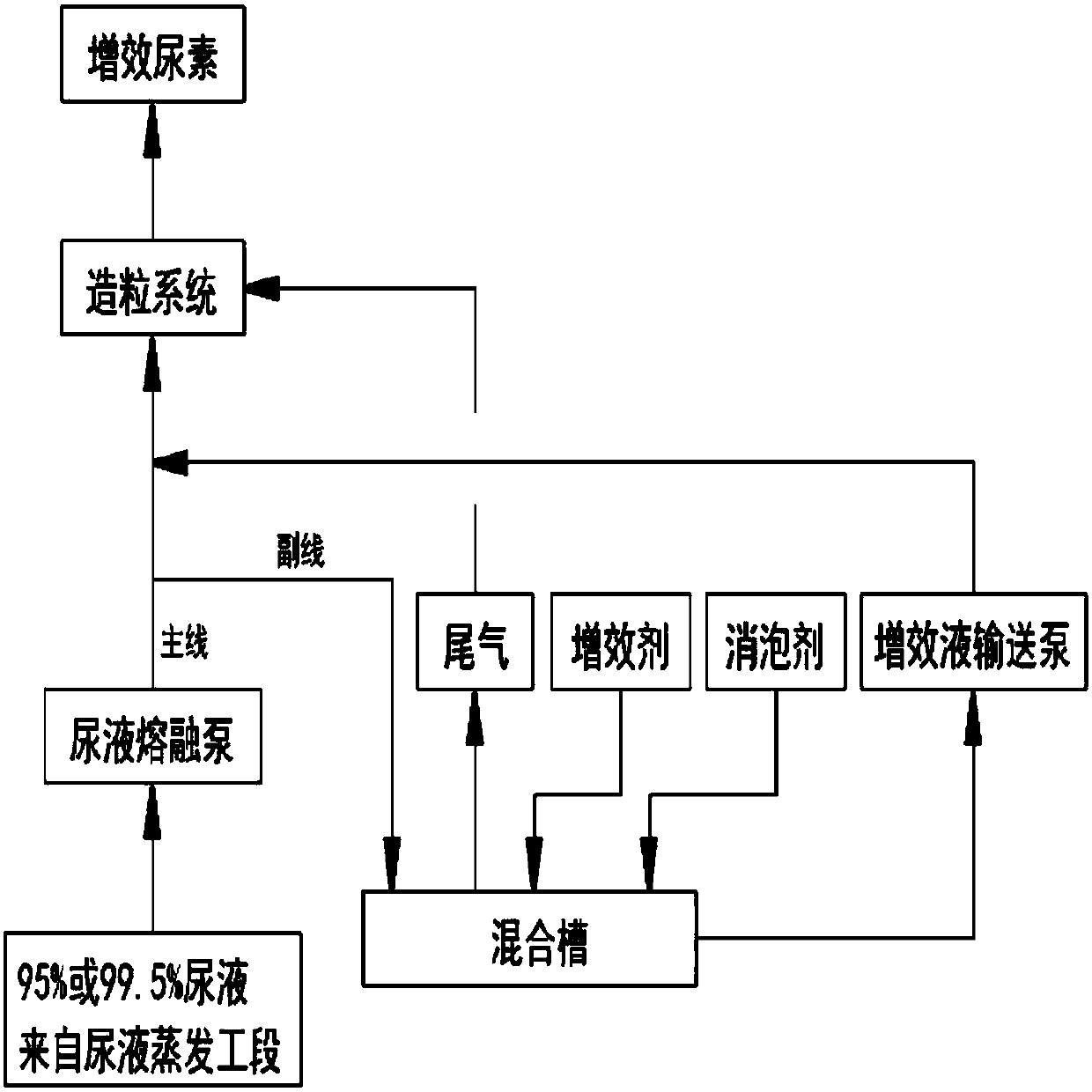

Production process of synergistic urea

A production process and urea technology, applied in the production process field of synergistic urea, can solve the problems of increasing system resistance, increasing energy consumption, increasing environmental protection pressure, etc., and achieving the effects of increasing system resistance, increasing energy consumption, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A production process of synergistic urea, comprising the steps of:

[0052] (1) Set the mass flow rate of the urine at the outlet main line of the urine melting pump to 20t / h, draw a stream of branch urine with a temperature of 135°C to 140°C from the main outlet line of the urine melting pump to the mixing tank, and Set its mass flow rate to 2t / h, turn on the defoamer delivery pump, add defoamer (silicon polyether defoamer (DF-1108)) into the mixing tank, and set the defoamer mass flow rate to 4kg / h, then open the synergist batching scale, add synergist (containing potassium fulvic acid, zinc, boron) in the mixing tank, the synergist mass flow rate is set to 200kg / h. Turn on the mixer and shear in the mixing tank to mix the slurry evenly.

[0053] (2) Send the mixed slurry obtained in step (1) back to the main line at the outlet of the urine melting pump through the slurry delivery pump, and enter the granulation system together with the urine in the main line to obt...

Embodiment 2

[0055] A production process of synergistic urea, comprising the steps of:

[0056] (1) Set the mass flow rate of the urine at the outlet main line of the urine melting pump to 28t / h, draw a stream of branch urine with a temperature of 135°C to 140°C from the main outlet line of the urine melting pump to the mixing tank, and Set its mass flow rate to 3t / h, turn on the defoamer delivery pump, add defoamer (organic silicon copolymer defoamer (1060)) into the mixing tank, and set the defoamer mass flow rate to 5.6kg / h, then open the synergist batching scale, add synergist (polyaspartic acid, zinc, boron) in the mixing tank, the synergist mass flow rate setting is 280kg / h. Turn on the mixer and shear in the mixing tank to mix the slurry evenly.

[0057] (2) Send the mixed slurry obtained in step (1) back to the main line at the outlet of the urine melting pump through the slurry delivery pump, and enter the granulation system together with the urine in the main line to obtain syn...

Embodiment 3

[0059] A production process of synergistic urea, comprising the steps of:

[0060] (1) Set the mass flow rate of the urine at the outlet main line of the urine melting pump to 72t / h, draw a stream of branch urine with a temperature of 135°C to 140°C from the main outlet line of the urine melting pump to the mixing tank, and Set its mass flow rate to 7t / h, open the defoamer delivery pump, add defoamer (polyether modified silicone defoamer (2354)) into the mixing tank, set the defoamer mass flow rate to 14kg / h, then open the synergist batching scale, add synergist (containing potassium fulvic acid, polyaspartic acid, zinc, boron) into the mixing tank, set the synergist mass flow rate to 125kg / h . Turn on the mixer and shear in the mixing tank to mix the slurry evenly.

[0061] (2) Send the mixed slurry obtained in step (1) back to the main line at the outlet of the urine melting pump through the slurry delivery pump, and enter the granulation system together with the urine in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com