Coating device

A coating device and nozzle technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as harming the physical and mental health of equipment operators, pollution of the slit coater, affecting the stable operation of the slit coater, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

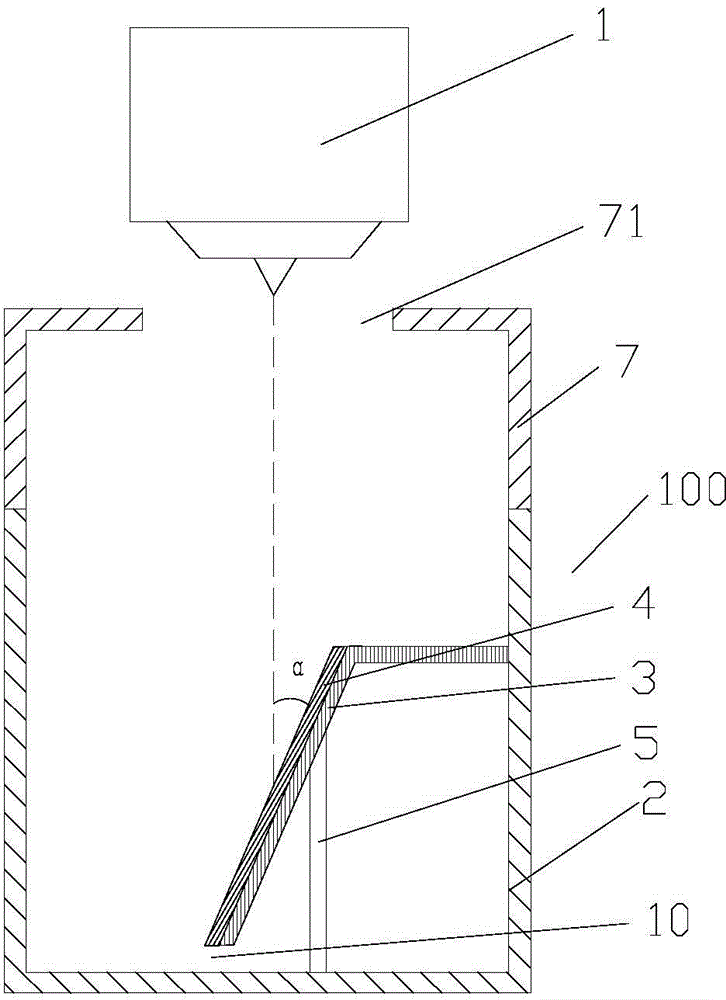

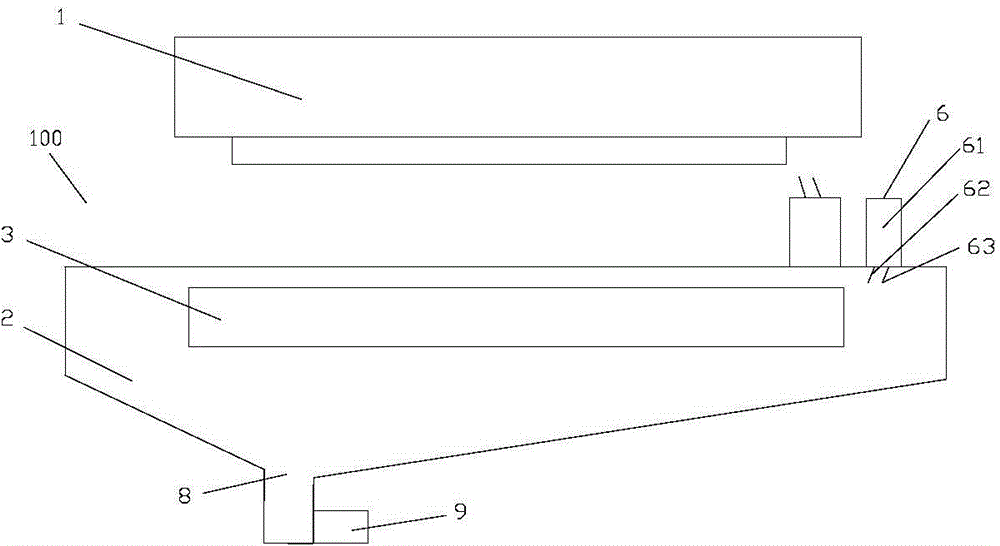

[0025] figure 1 The structure of the coating device 100 is shown. Such as figure 1 As shown, the coating device 100 includes a nozzle 1 , a receiving tray 2 and a deflector 3 arranged in the receiving tray 2 . During the production of electronic devices such as thin film transistors and color filters, the nozzle 1 is used to coat photoresist on, for example, a glass substrate. The receiving tray 2 is arranged under the nozzle 1, and can collect the photoresist ejected from the nozzle 1 during pre-discharging and the like. The deflector 3 is arranged along the longitudinal direction of the receiving tray 2 and can form a first angle α with the vertical for receiving the fluid ejected from the nozzle 1 .

[0026] Therefore, before coating the photoresist or during the process of photoresist transfer, it is necessary to carry out a pre-spraying extrusion cleaning (Purge) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com