Method of forming thin-wall blank step by step with multi-rod force application

A billet and thin-walled technology, applied in the field of gradual forming of thin-walled billets, can solve the problems of uncontrollable large-size thin-walled billets, thinning or wrinkling, forming deformation, etc., and achieve simple structure, improved uniformity, and stress-bearing state reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

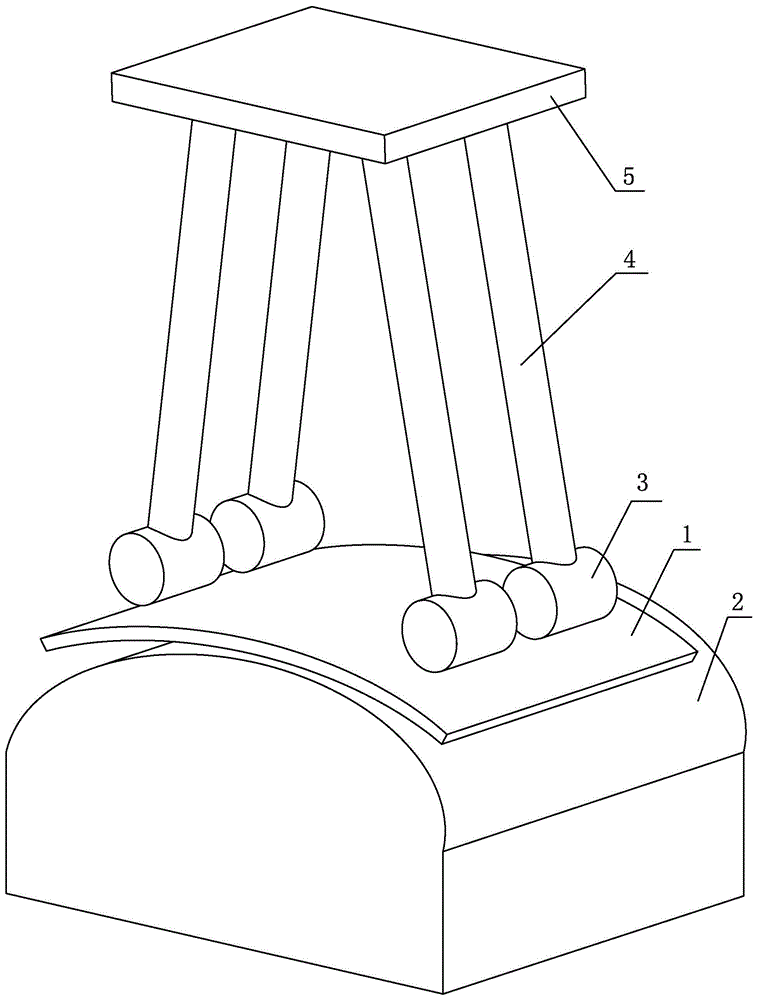

[0025] Specific implementation mode one: combine Figure 1-10 Explain that a step-by-step forming method for thin-walled blanks with multi-rod application of force in this embodiment is realized according to the following steps:

[0026] Step 1. Place the blank 1 that has been cut to be formed on the forming mold 2, and position and fix the blank 1;

[0027] Step 2, the force application platform 5 moves towards the forming mold 2 under the action of the press; wherein, the lower end surface of the force application platform 5 is rotatably connected with a plurality of force application rods 4;

[0028] Step 3, each connected forming head 3 on the plurality of force application rods 4 is in sliding contact with the blank 1, and at the same time, each reaction force element connected between the force application platform 5 and the plurality of force application rods 4 corresponds to the corresponding force application The rod 4 exerts a counter force, so that the forming head...

specific Embodiment approach 2

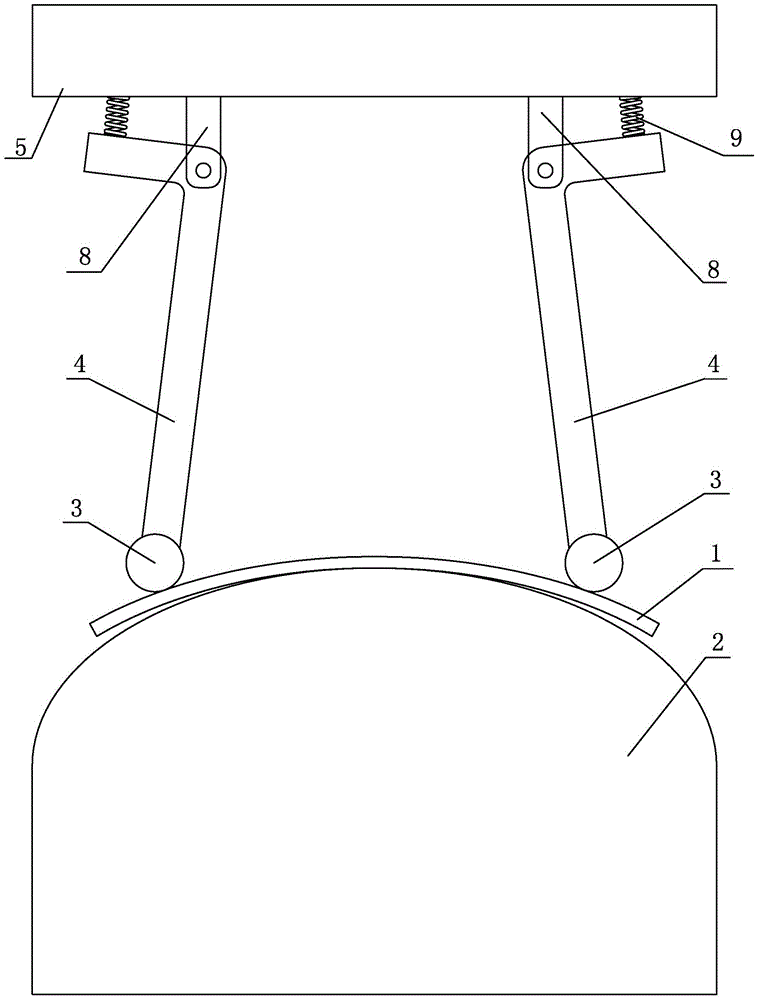

[0032] Specific implementation mode two: combination figure 1 and figure 2 Explain that the reaction force element in the step 3 of the present embodiment is a spring 9, and a plurality of force application rods 4 are curved rods, and the force application rods 4 are rotatably connected to the support rod 8 fixedly connected with the force application platform 5, and the force application The bend of the rod 4 can rotate around the support rod 8, one end of the spring 9 is connected with the force application platform 5, the other end of the spring 9 is connected with one end of the force application rod 4, the other end of the force application rod 4 is connected with the forming head 3, and the spring When 9 is compressed, a reaction force is generated to act on the force application rod 4, so that the forming head 3 connected with the force application rod 4 generates a force acting on the blank 1 to realize the deformation of the blank 1.

[0033] When the spring 9 of th...

specific Embodiment approach 3

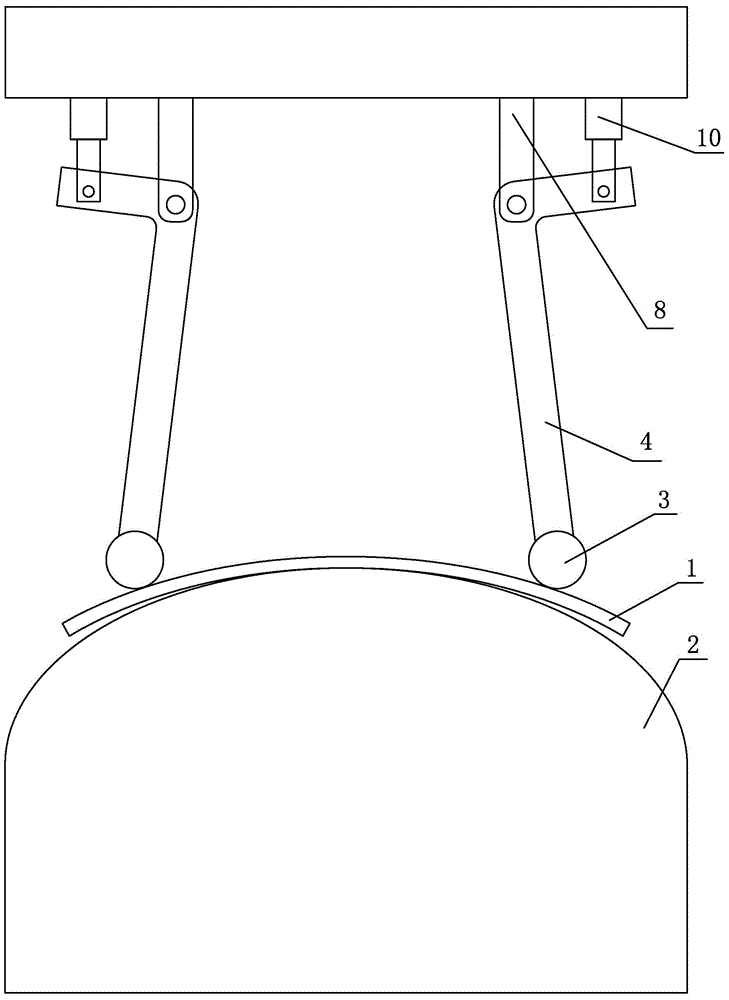

[0034] Specific implementation mode three: combination figure 1 and image 3 Explain that the reaction force element in step 3 of this embodiment is an oil cylinder 10, and a plurality of force application rods 4 are curved rods. The bend of the rod 4 can rotate around the support rod 8, the oil cylinder 10 is fixed on the lower surface of the force application platform 5, the driving rod of the oil cylinder 10 is connected with one end of the force application rod 4, and the other end of the force application rod 4 is connected with the forming head 3, When the oil cylinder 10 is compressed, a reaction force is generated to act on the force applying rod 4 , so that the forming head 3 connected with the force applying rod 4 generates a force acting on the blank 1 to realize the deformation of the blank 1 .

[0035] When the oil cylinder 10 of the present embodiment is compressed, a reaction force acts on the force application rod 4. The force application rod 4 is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com