A large-size bearing dismounting device that helps to improve dismounting efficiency

A high-efficiency, bearing technology, applied in the field of large-size bearing disassembly and assembly devices, can solve the problems of shaft and rolling bearing damage, complex disassembly and assembly tools, and increased production costs, and achieve reliable work, short disassembly and assembly time, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements based on the teaching of the present invention fall within the scope of protection of the present invention.

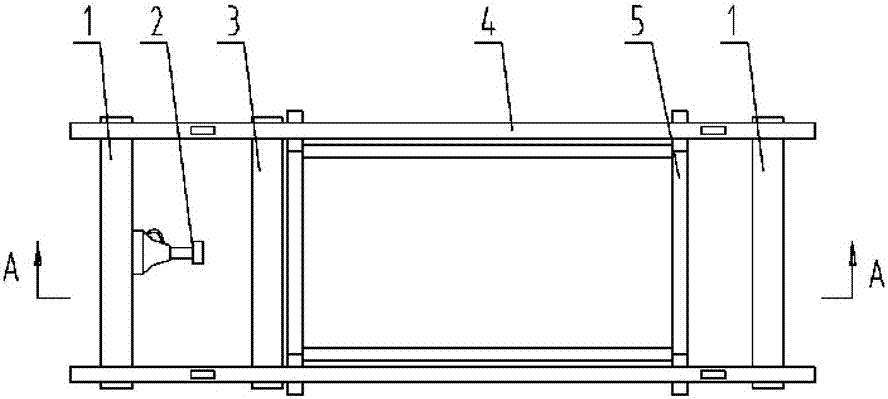

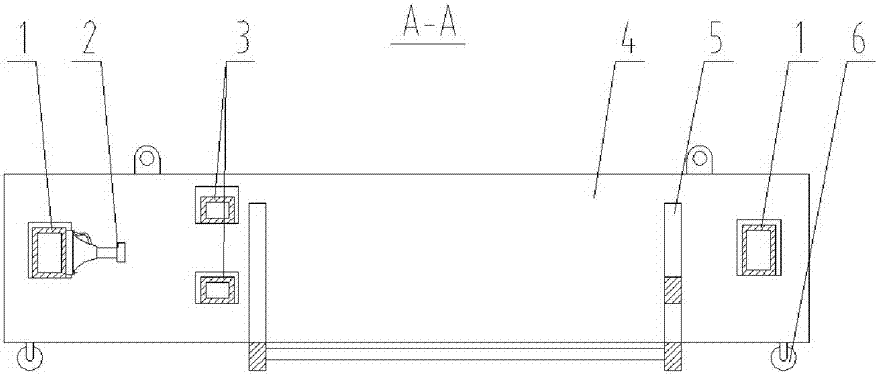

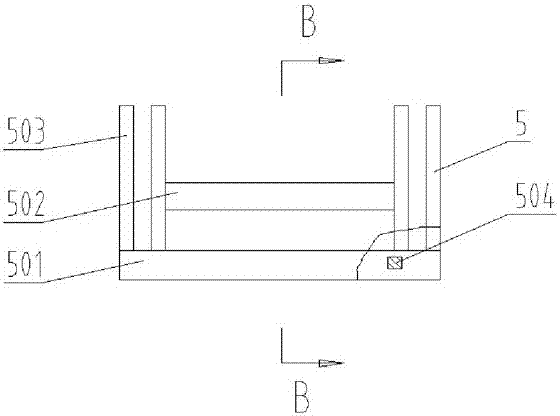

[0020] Such as figure 1 As shown in ~ 8, the present invention comprises a main beam 1, a force applying device 2, an auxiliary beam 3, a vertical plate 4, and a base frame 5, and the two sides of the base frame 5 are respectively provided with a vertical plate 4; Insert into the through groove of the column 503 of the pedestal 5, and they are clearance fit with each other; the two ends of the vertical plate 4 are respectively provided with the main beam 1; A secondary beam 3 is also set between the frames 5; the side of the main beam 1 close to the secondary beam 3 is provided with a force applying device 2, and the bottom of the force applying device 2 is supported and matched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com