Automatic control sand blasting machine

A sandblasting machine and sandblasting technology, applied in the field of sandblasting machines, can solve problems such as time-consuming work, inapplicability to products of different specifications, and uncontrollable rotation speed of the turntable, so as to save working time and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

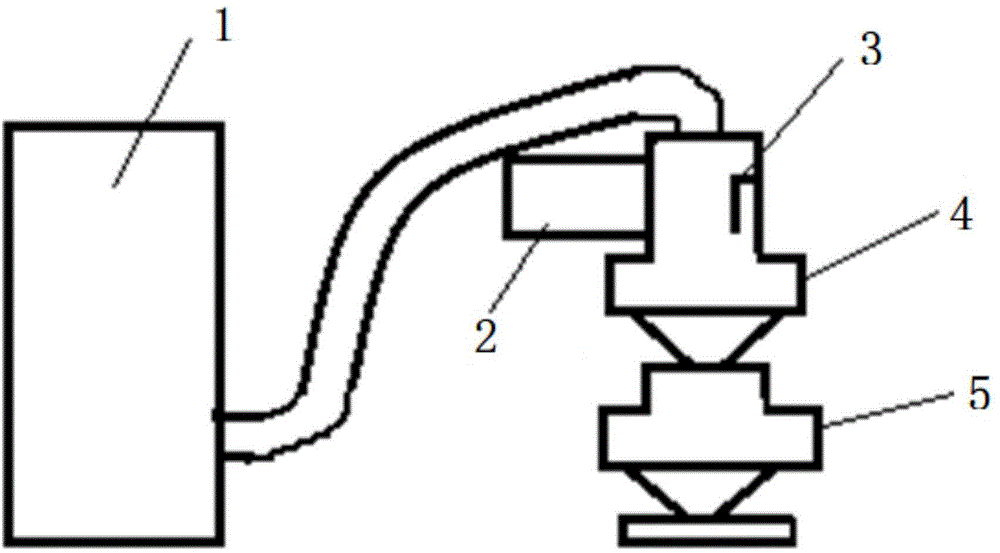

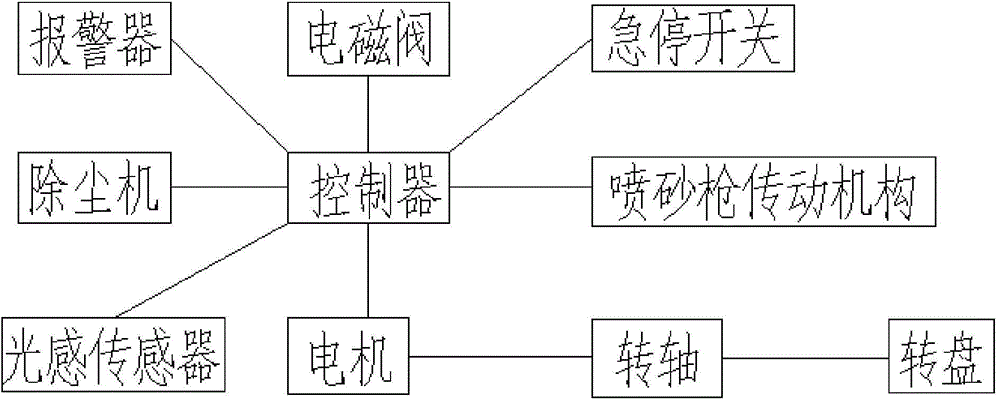

[0024] Such as Figure 1-2 As shown, the present invention provides an automatic control sandblasting machine, comprising a dust collector 1, an electronic control box 2, a sandblasting gun 3, a turntable 4, and an air compressor 5, the turntable 4 is provided with a sealing cover, and the spray The sand gun 3 is arranged in the sealed cover, the dust remover 1 is connected with the sealed cover through a pipeline, the electronic control box 2 is arranged on one side of the sealed cover, and the air compressor 5 is located in the sealed cover. One end of the turntable 4, the sandblasting gun 3 includes a nozzle and a sandblasting pipeline, and the air compressor 5 includes an air intake end and an exhaust end, and the exhaust end is connected with the nozzle through the sandblasting pipeline, The air compressor 5 is used to provide sandblasting power for the sandblasting gun 3 .

[0025] Preferably, a rotating shaft is provided at the center of the turntable 4, the rotating s...

Embodiment 2

[0039] Such as Figure 1-2As shown, the present invention provides an automatic control sandblasting machine, comprising a dust collector 1, an electronic control box 2, a sandblasting gun 3, a turntable 4, and an air compressor 5, the turntable 4 is provided with a sealing cover, and the spray The sand gun 3 is arranged in the sealed cover, the dust remover 1 is connected with the sealed cover through a pipeline, the electronic control box 2 is arranged on one side of the sealed cover, and the air compressor 5 is located in the sealed cover. One end of the turntable 4, the sandblasting gun 3 includes a nozzle and a sandblasting pipeline, and the air compressor 5 includes an air intake end and an exhaust end, and the exhaust end is connected with the nozzle through the sandblasting pipeline, The air compressor 5 is used to provide sandblasting power for the sandblasting gun 3 .

[0040] Preferably, a rotating shaft is provided at the center of the turntable 4, the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com