Injection molding method for two-color injection molded parts and injection mold implementing the method

An injection mold and injection molding technology, applied in the field of mold manufacturing, can solve the problems of complex control of injection molding machines, increase of injection molding cycle, error-prone machine adjustment, etc., to overcome the inability to control the action sequence, reduce the size and thickness of the mold, and avoid traditional The effect of using the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

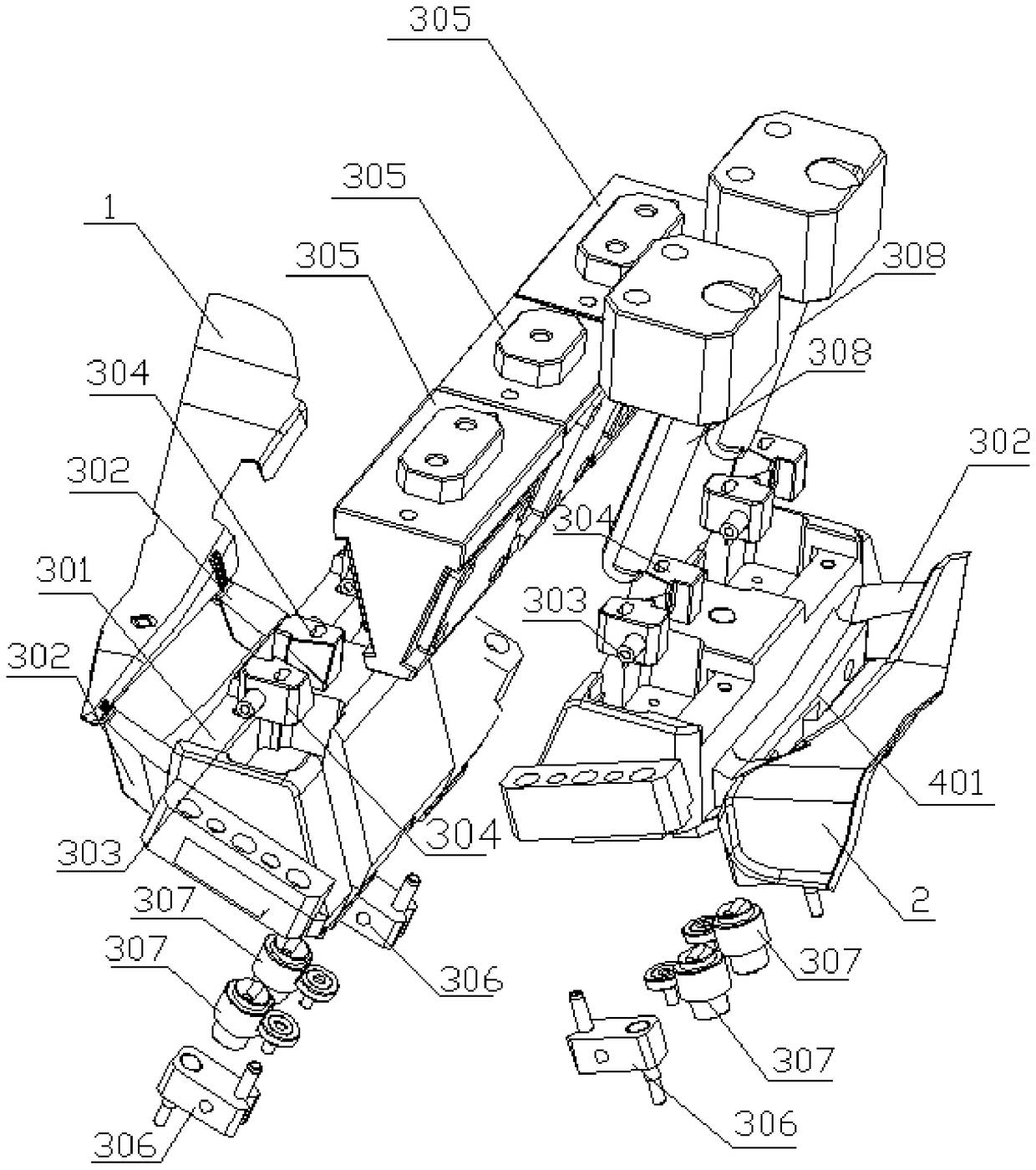

[0027] Example: see Figures 1 to 4 , a method for injection molding a two-color injection molded part provided in this embodiment, which includes the following steps:

[0028] (1) An injection molding machine and an injection mold are set, the injection mold is set on the injection molding machine, and its working state is controlled by the injection molding machine;

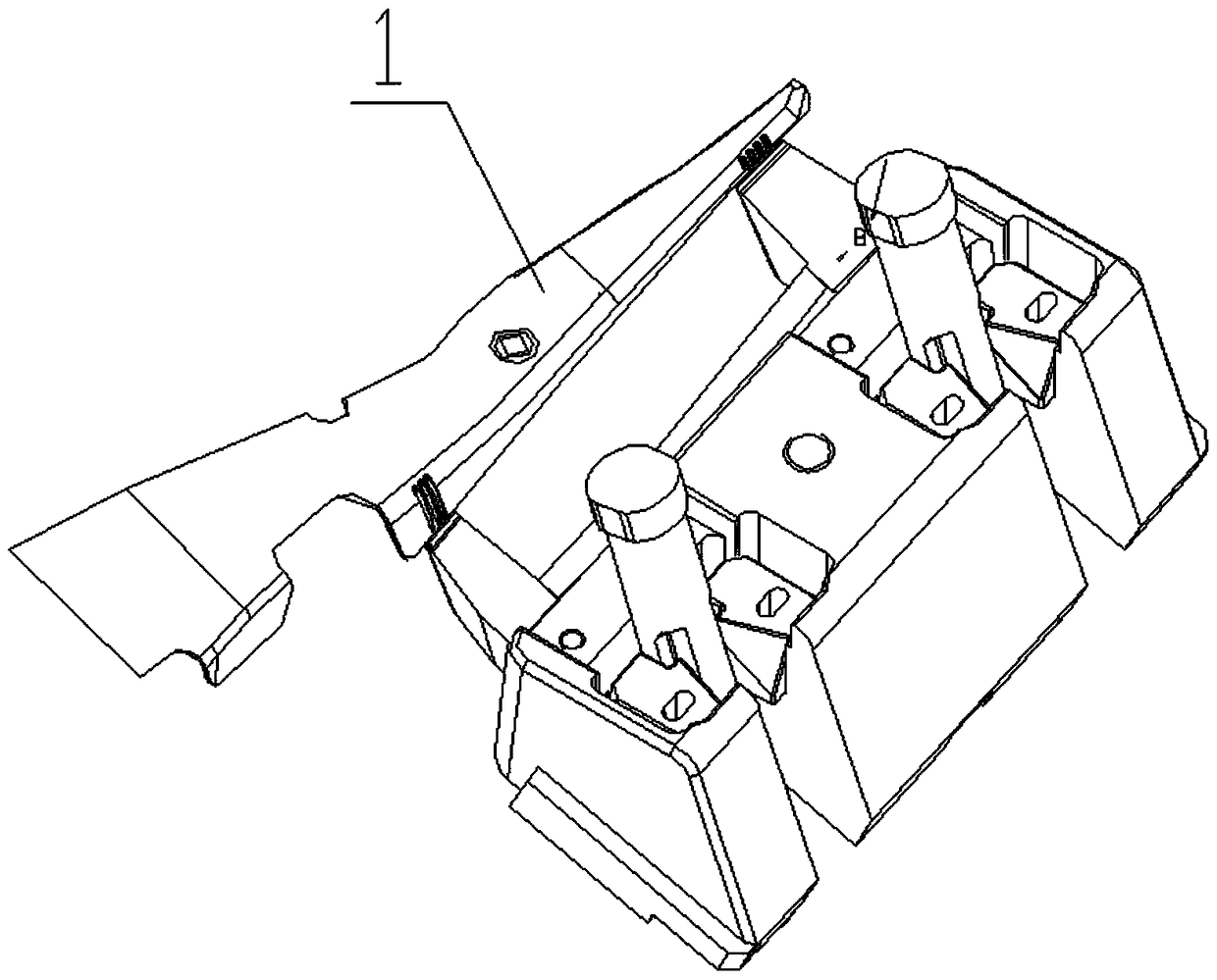

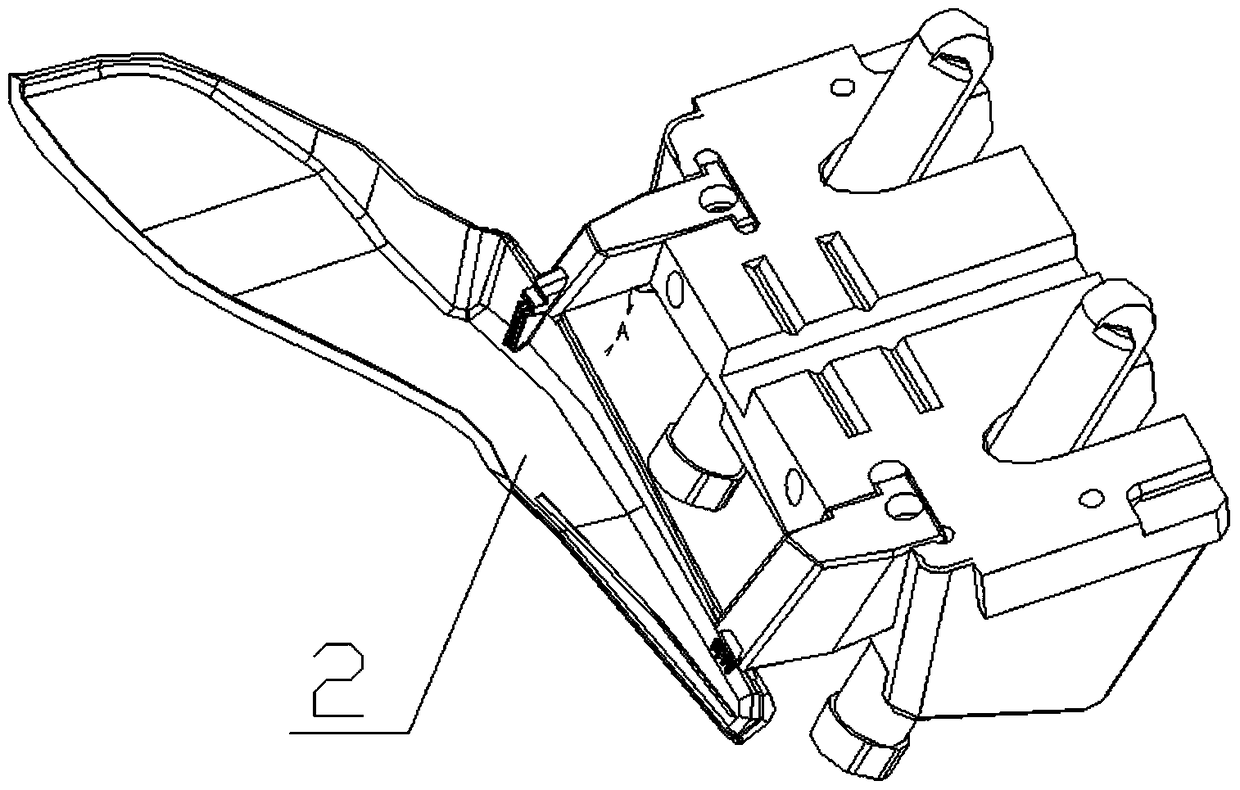

[0029] (2) A mechanical drive slider mechanism is set in the injection mold, and the mechanical drive slider mechanism includes a hard rubber slider assembly and a soft rubber slider assembly for molding, and the hard rubber slider assembly and the soft rubber slider assembly The slider assembly includes slider body 301, 401, slider insert 302, spring 303, dial 304, locking block 305, first locator 306 and second locator 307, and the soft rubber slider assembly also An inclined guide post 308 is provided;

[0030] (3) The injection molding machine closes the mold, the hard rubber slider 301 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com