train noise reduction wheels

A wheel and noise reduction technology, applied in the field of transportation, can solve problems such as adhesive layer failure and peeling, achieve structural stability, increase vibration energy consumption, and reduce sound radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

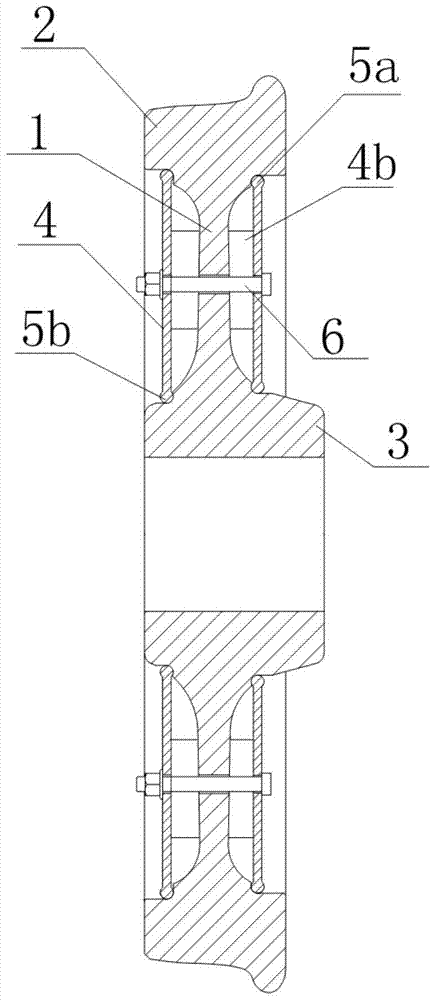

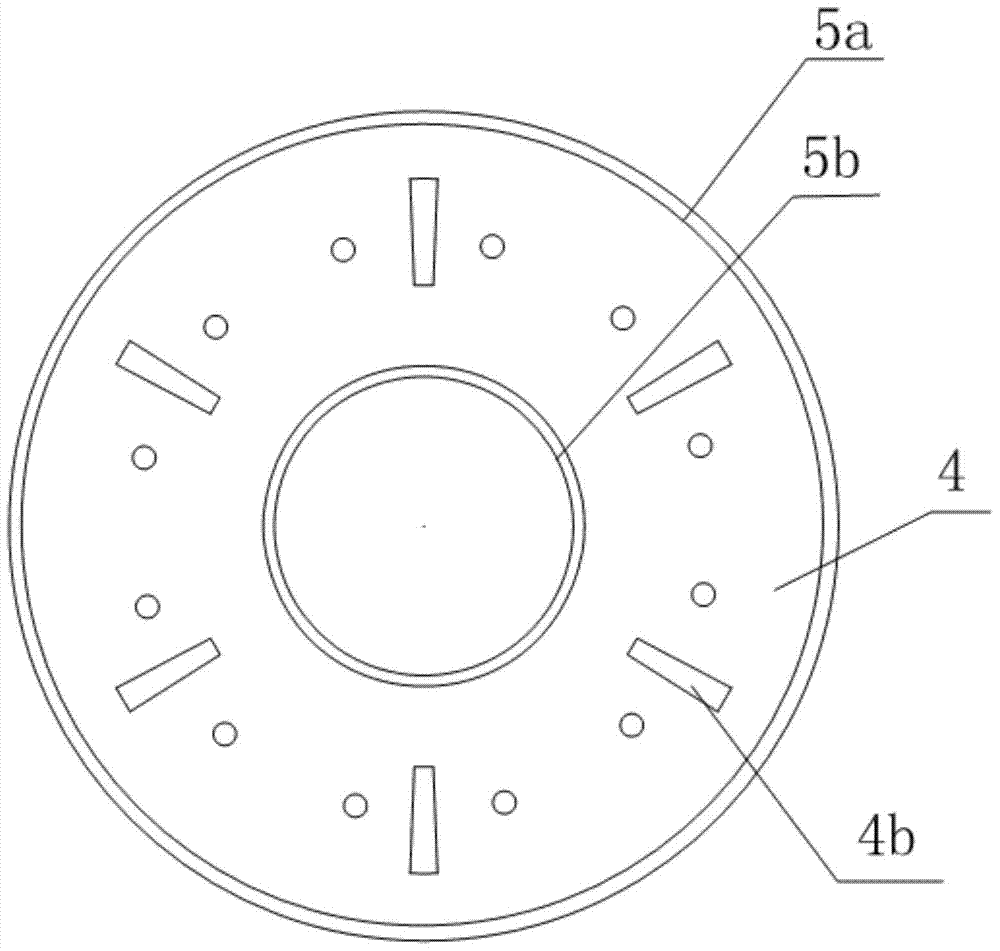

[0027] figure 1 , figure 2 and image 3 As shown, a specific embodiment of the present invention is: a noise reduction wheel for a train, including a web plate 1, a rim 2 and a hub 3, and its structural feature is: both sides of the web plate 1 of the wheel are fixed by bolts 6 An annular noise shielding plate 4, the outer edge of the noise shielding plate 4 is in contact with the rim 2 of the wheel, and the inner edge is in contact with the hub 3 of the wheel.

[0028] In this example, the outer edge of the noise shielding plate 4 is in contact with the rim 2 of the wheel, and the specific way in which the inner edge is in contact with the hub 3 of the wheel is: the outer edge of the noise shielding plate 4 is an arc-shaped protrusion The outer damping ring joint 5a is formed, and the outer damping ring joint 5a is in contact with the rim 2 of the wheel; the inner ring edge of the noise shielding plate 4 is a circular arc-shaped protrusion to form the inner damping ring jo...

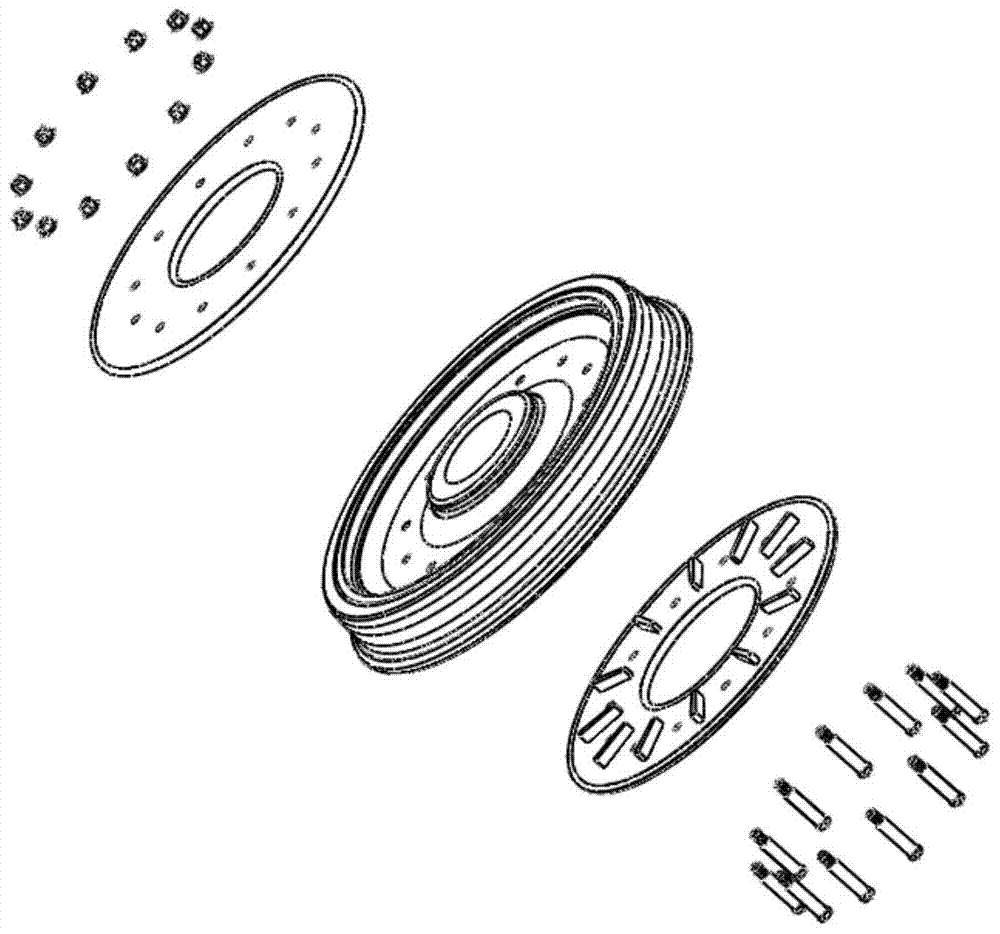

Embodiment 2

[0033] The structure of this example and embodiment one is basically the same, and the difference is only: the annular noise shielding plate 4 described in this example is made up of more than two fan-shaped shielding blocks 4a, as Figure 4 shown. Figure 5 It is a schematic diagram of the assembly and decomposition of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com