Floor-drain inner core and deodorization floor drain with floor-drain inner core

A technology of inner core and floor drain, which is applied to waterway systems, drainage structures, water supply devices, etc. It can solve the problems of inability to deodorize, floor drains are easy to slip, and difficult to disassemble, and achieve the effect of easy daily cleaning, good deodorization effect, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

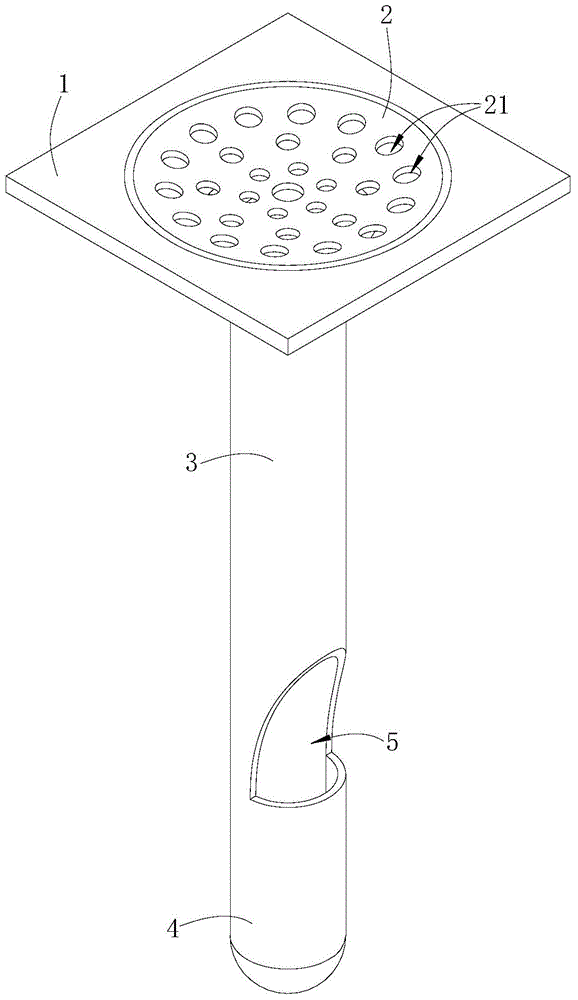

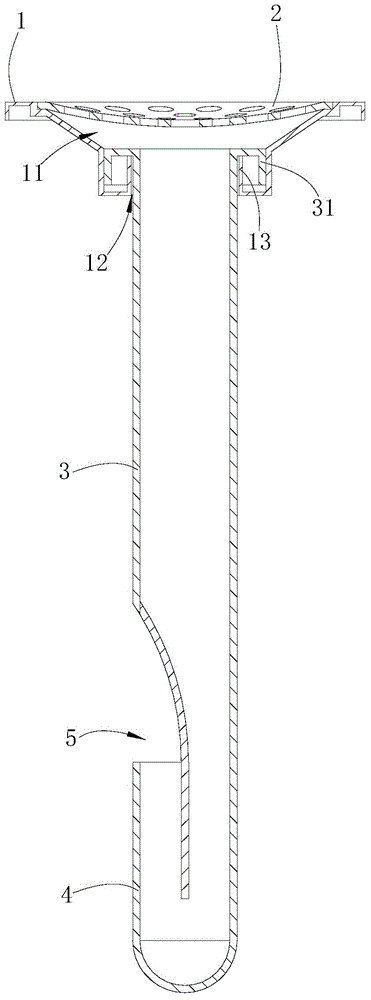

[0039] Such as Figure 1 to 2 Shown

[0040] The deodorant floor drain includes a panel 1 and a cover 2. The upper end of the panel 1 has a drainage groove 11 formed by a depression, a drainage hole 12 is provided at the bottom of the drainage groove 11, and a shoulder 13 extends upward from the edge of the drainage hole 12. On the upper part of the drainage groove 11 of the panel 1, the upper end surface of the cover plate 2 has a spherical depression, and the cover plate 2 has a plurality of through holes 21;

[0041] The drain hole 12 of the panel 1 is provided with a floor drain inner core. The floor drain inner core includes a catheter 3 and a liquid seal part 4. The catheter 3 and the liquid seal part 4 of the floor drain inner core are an integrated structure. The upper end of the catheter 3 An outer convex ring 31 extends outward. The outer convex ring 31 cooperates with the shoulder 13 of the panel 1 so that the upper end of the catheter 3 completely covers the drainage ho...

Embodiment 2

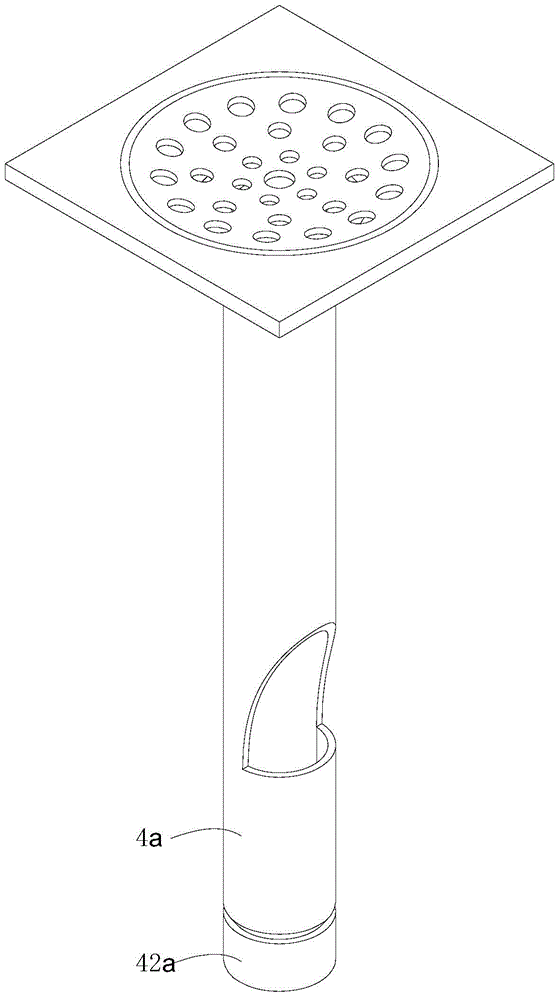

[0043] Such as Figure 3 to 4 Shown

[0044] The only difference between this embodiment and the first embodiment is that the bottom of the liquid sealing portion 4a is provided with a dredging hole 41a, the dredging hole 41a is provided with a screw cap 42a, and the screw cap 42a is threadedly connected with the side wall of the liquid sealing portion 4a.

Embodiment 3

[0046] Such as Figure 5 to 6 Shown

[0047] The deodorant floor drain includes a panel 1b and a cover 2b. The upper end of the panel 1b has a drainage groove 11b formed by a depression. The bottom of the drainage groove 11b has a drainage hole 12b. The edge of the drainage hole 12b is extended with a shoulder 13b. The cover plate 2b is arranged on On the upper part of the drainage groove 11b of the panel 1b, the upper end surface of the cover plate 2b has a spherical depression, and the cover plate 2b has a plurality of through holes 21b;

[0048] The drain hole 12b of the panel 1b is provided with a floor drain inner core. The floor drain inner core includes a catheter 3b and a liquid sealing part 4b. The catheter 3b and the liquid sealing part 4b of the floor drain inner core are of a separate structure. The upper end of the catheter 3b An outer convex ring 31a extends outward, and the outer convex ring 31a cooperates with the shoulder 13b of the panel 1b so that the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com