Apparatus for connecting deformed bar

A technology for deforming steel bars and connecting devices, which is applied in the construction, building structure, and building material processing, etc., can solve the problems of large operation time, low connection processing cost, and inability to connect, so as to save construction costs, save operation time, The effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

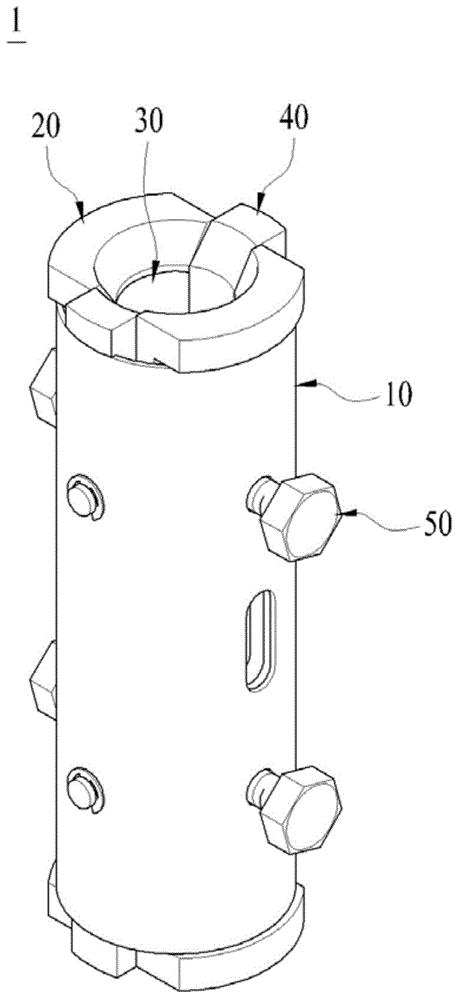

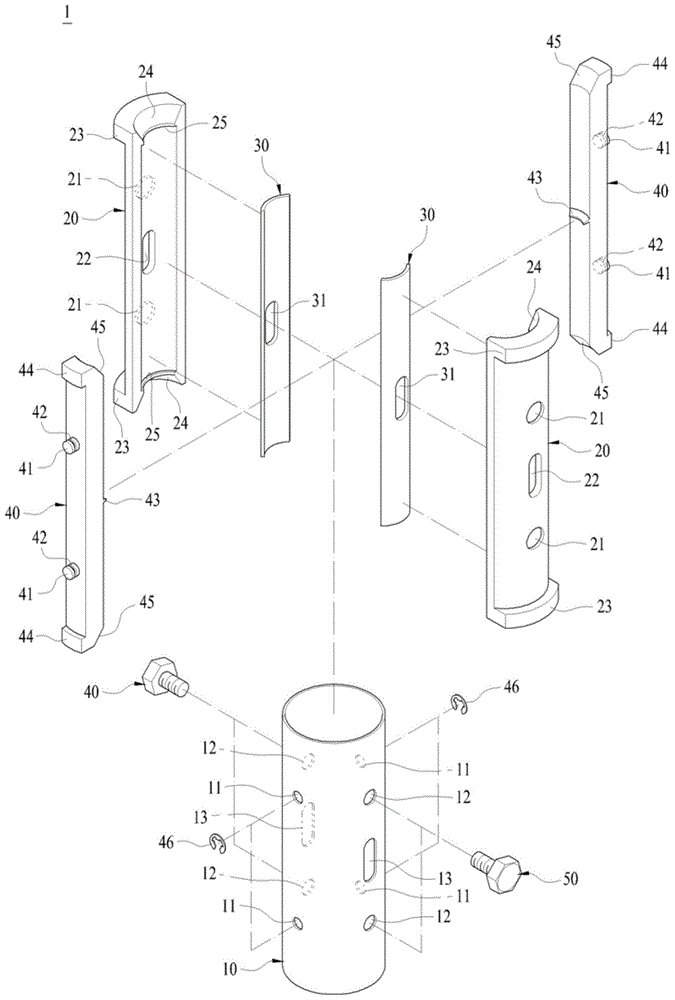

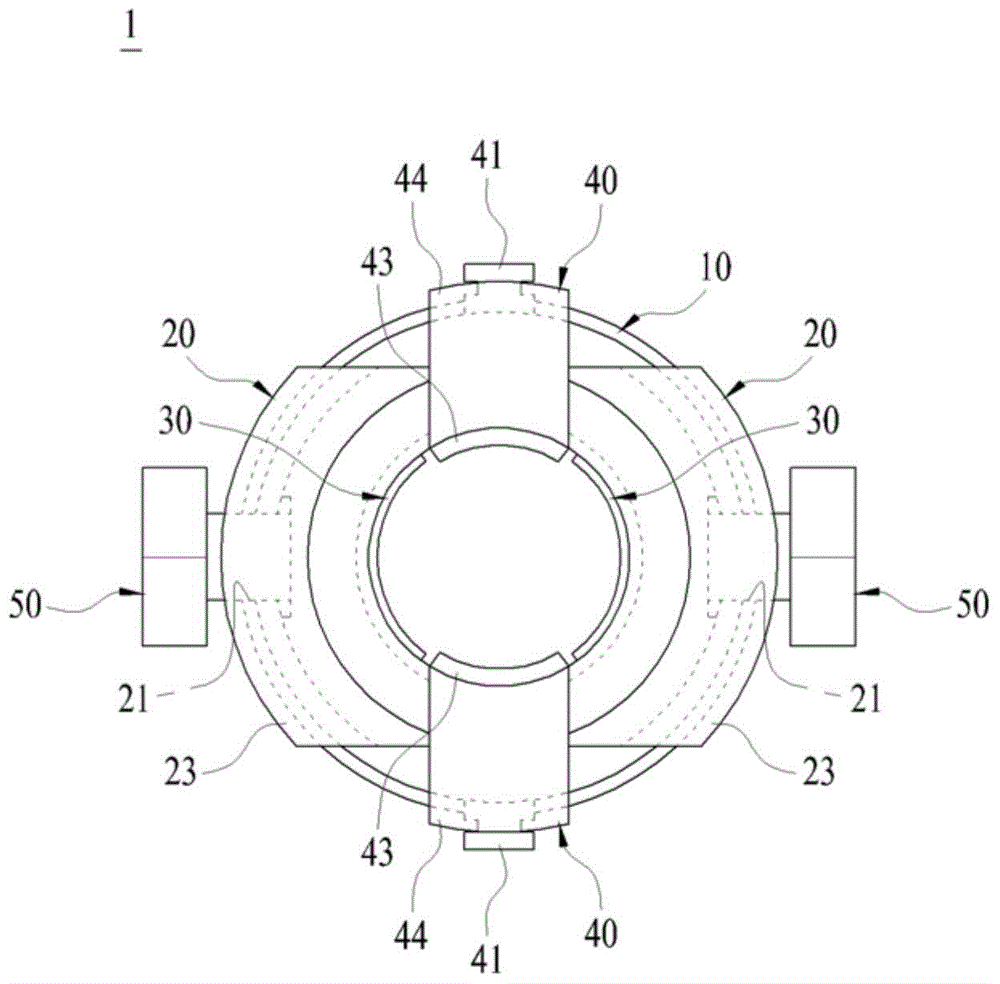

[0060] figure 1 Among them, the connecting device 1 for connecting deformed steel bars has a pair of pressing members 20 and a pair of partition members 40 built in a cylindrical shell 10, the inner surface of the pressing members 20 is joined with a mat 30, and a fixing member 50 is joined. , apply pressure to the pressing parts 20 from the outside, and fix the deformed steel bar between the pressing parts 20 .

[0061] exist figure 2 , the housing 10 is a cylinder with a predetermined diameter, and a plurality of through holes 11 and fixing holes 12 are formed through the periphery. The through holes 11 are respectively formed in the upper part and the lower part, and are formed through the outer peripheral surface oppositely at an angle of about 180 degrees. The fixing holes 12 are respectively formed in the upper part and the lower part, and formed through the outer peripheral surface oppositely at an angle of about 180 degrees. Therefore, the through hole 11 and the f...

no. 2 Embodiment

[0076]The structural features of the second embodiment include: a cylindrical shell formed with a predetermined diameter, and a plurality of through holes and fixing holes are formed through the periphery, and a plurality of through holes and fixing holes are formed between the through holes and the fixing holes. a through hole; a pair of arc-shaped pressure-applying parts, which are inserted into the housing, with flanges formed on the upper and lower parts, and a plurality of fixing grooves formed on the outer surface; arc-shaped cushions, which are elastic, are joined to the pressure-applying parts The inner surface; a pair of arc-shaped partition parts, inserted between the pair of pressing parts, the upper and lower parts are formed with flanges, and the center of the outer surface protrudes to form a protrusion; the fixing part is screwed through the fixing hole, and the end The part is in contact with the fixing groove; the nut-shaped part has a second through hole insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com