A radial and axial double-locking marine drill pipe threaded joint

A technology of threaded joints and external threaded joints, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high replacement cost, harsh connection requirements, and affecting the operation efficiency of oil drill pipes, and achieve the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

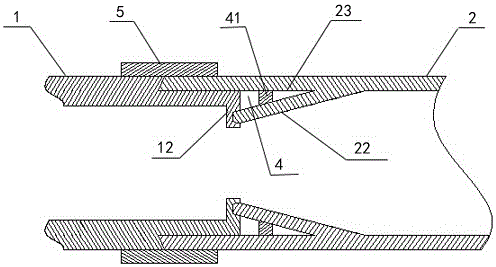

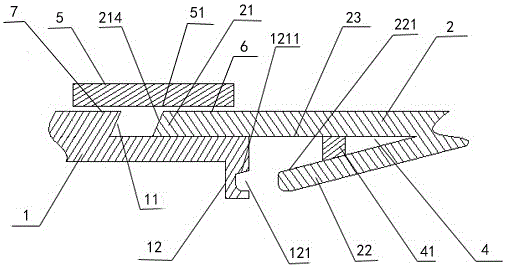

[0028] like figure 1 and 2 As shown, a radial and axial double-locking marine drill pipe threaded joint includes an external threaded joint 1 and an internal threaded joint 2 . The externally threaded joint 1 and the internally threaded joint 2 are in a cylindrical structure, and a pipeline for offshore oil transportation is arranged on the inner side thereof. An outer shoulder surface 11 is provided on the outer side of the externally threaded joint 1 . The external thread joint 1 and the internal thread joint 2 are threadedly connected. It also includes a locking sleeve 5, the locking sleeve 5 has a columnar structure with two ends open, and the inner side of the locking sleeve 5 is provided with locking threads 51. The outer surface of the externally threaded joint 1 is provided with a first connecting thread 7 , and the external surface of the internally threaded joint 2 is provided with a second connecting thread 6 . The first connecting thread 7 and the second connec...

Embodiment 2

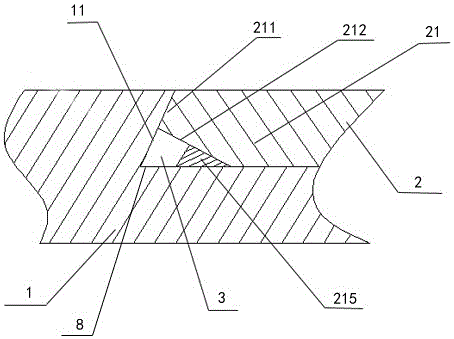

[0031] like image 3 As shown, this embodiment refers to Embodiment 1, and the difference lies in that the end surface 214 of the internally threaded joint includes a contact slope 211 and a connection slope 212 . The connection slope 212 is disposed inside the contact slope 211 . The inclination directions of the contact slope 211 and the outer shoulder surface 11 are consistent. The inclination directions of the connection slope 212 and the contact slope 211 are opposite. An annular gap 3 is formed between the connecting slope 212 , the outer shoulder surface 11 and the outer wall 8 of the externally threaded joint 1 . The annular gap 3 formed between the connecting slope 212, the outer shoulder surface 11 and the outer wall 8 of the external threaded joint 1 reduces the weight of the internal threaded joint 2, making it easier for the external threaded joint 1 to generate radial force on the internal threaded joint 2 The effect further enhances the radial locking force o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap