A joint optimization and control method for mine ventilation system

A mine ventilation system and ventilation system technology, applied in mine/tunnel ventilation, pump control, mining equipment, etc., can solve the problems that the maximum resistance path adjustment method is not feasible, the calculation results are not in line with reality, and the wind resistance is negative.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention is described in detail below in conjunction with accompanying drawing:

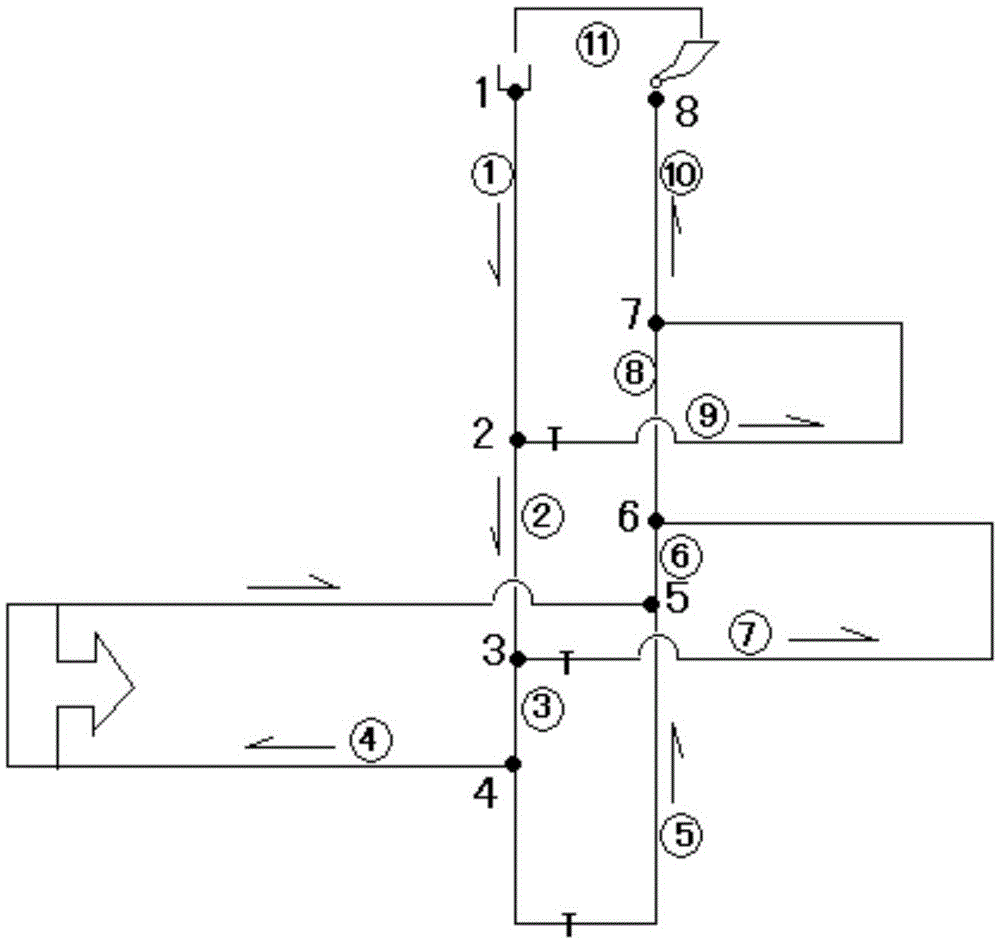

[0078] Step 1, establish and number the complete topological structure diagram of the mine ventilation system network, and form a ventilation system network diagram for optimal control calculation;

[0079] Such as figure 1 Shown is a specific example of the network diagram of the ventilation system obtained by figure 1 It can be seen that the ventilation system has a total of 11 air ducts, which are divided into four categories according to their respective uses.

[0080] Here, the air ducts of type I are: air duct 11; the air ducts of type II are: air ducts 4, 7 and 9; the air ducts of type III are air ducts 5, 7 and 9; That is: duct 1, 2, 3, 6, 8, 10.

[0081] Step 2, since the ventilation system has 11 air ducts and 8 nodes, there are 11-8+1=4 independent circuits in total. Select air ducts 4, 5, 7, and 9 as independent air ducts, and the following basic circuit matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com