A Joint Adjustment Method of Nozzle and Test Section in Plane Cascade Subsonic Test Device

A test device and test section technology, applied in the field of aero-engine basic research and test equipment, can solve the problems of no nozzle outlet height adjustment, high labor intensity, sudden change in nozzle outlet size, etc., so as to save the test preparation time and improve the test Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

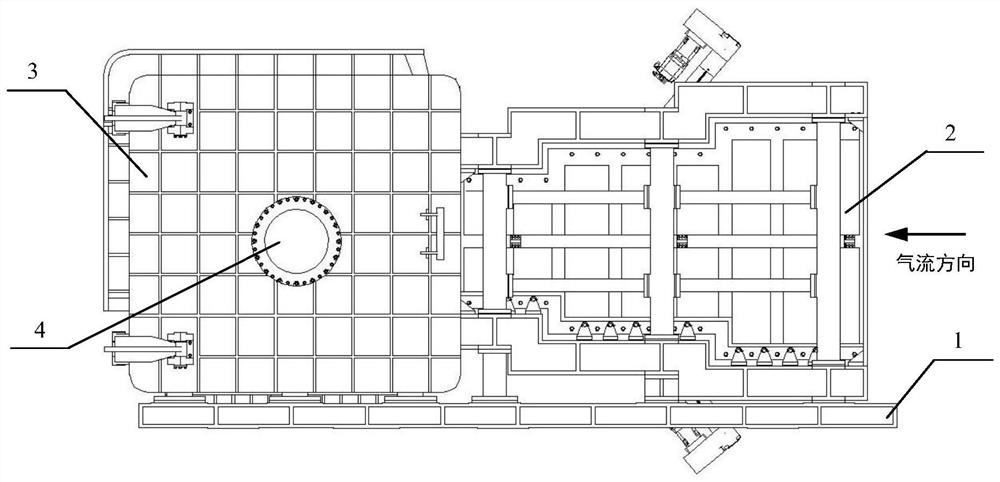

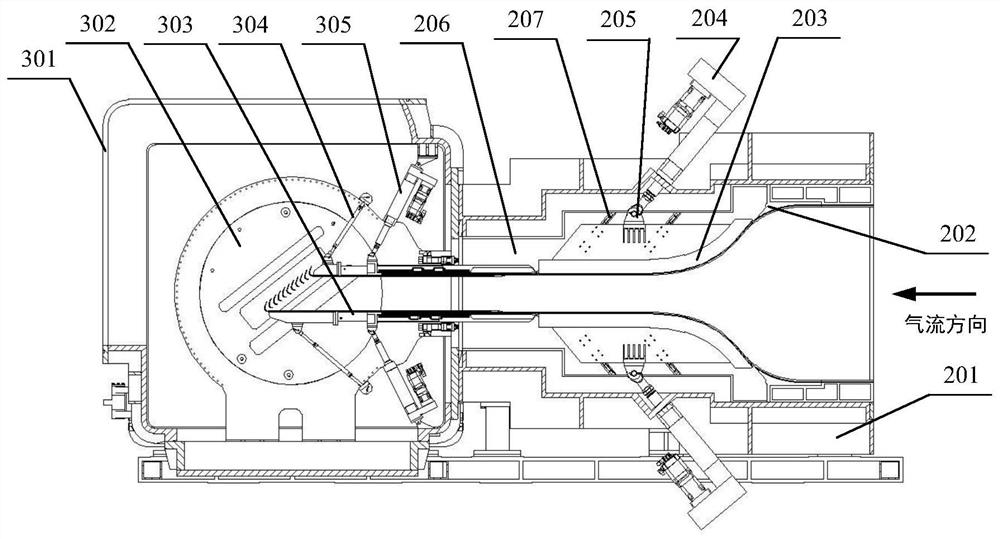

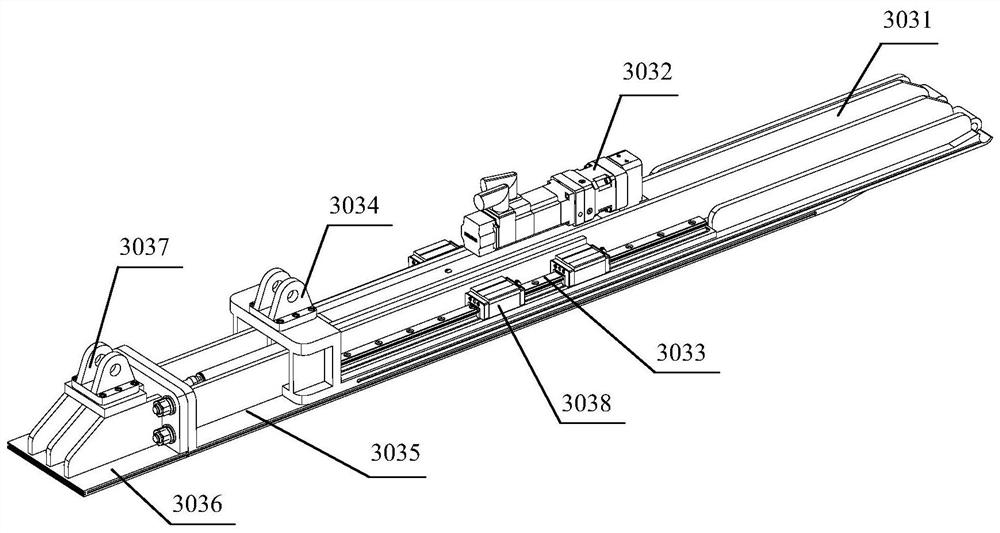

[0061] In the planar cascade subsonic test device of this embodiment, the joint adjustment method of the nozzle and the test section is used. The height-adjustable sonic nozzle 2 of the planar cascade subsonic test device used in the joint adjustment method is 1340 mm high × 190 mm wide. , Adjustable height The outlet height of the sonic nozzle 2 can be adjusted from 235mm to 445mm; the angle of the upper and lower panels can be adjusted from -5° to 5°, and the length of the upper and lower panels can be adjusted from 0 to 400mm.

[0062] The flow field calibration test shows that the deviation of the core area of the flow field in the test section of the subsonic test chamber 3 is better than 0.003 when the Mach number is 0.8, which has reached the advanced level of GJB 1179A-2012 in the "Quality Requirements for Flow Fields of Low-speed Wind Tunnels and High-speed Wind Tunnels". index.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com