Double-nozzle type giant magnetostrictive jet servo valve and working method

A technology of giant magnetostrictive and giant magnetostrictive rods, which is applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of energy loss, servo valve performance degradation, large volume, etc., to reduce thermal expansion Combined with heat-induced displacement, improved output displacement accuracy, and high displacement output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

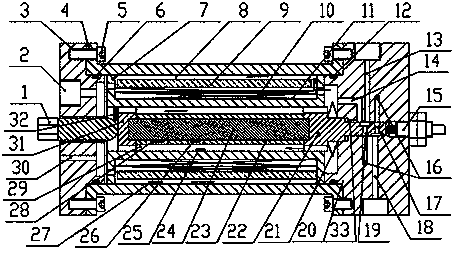

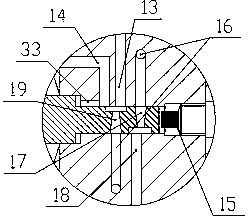

[0054] Such as figure 1 , shown in 2 and 3, a dual-nozzle type giant magnetostrictive jet servo valve, comprising a giant magnetostrictive electric-machine converter and a jet amplifier, is characterized in that:

[0055] The above-mentioned giant magnetostrictive electro-mechanical converter includes an outer cover 4, a left end cover 3 and a right end cover 20 installed at two ends of the outer cover, a bobbin 7 installed in the outer cover, one end of the bobbin 7 is fixed with the right end cover 20, and the other end is connected with the left end cover. There is a gap in the cover 3; a bias magnetic field generating unit and a driving magnetic field generating unit are installed on the coil bobbin 7;

[0056] It also includes a giant magnetostrictive rod 24 installed in the coil frame 7. The side of the giant magnetostrictive rod 24 close to the left end cover is a magnetic fixed end, and the fixed end of the magnetostrictive rod is equipped with a slider 31, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com