System and method for improving the response time of an engine using model predictive control

A model predictive control, engine technology, applied in general control systems, control/regulation systems, combustion engines, etc., can solve problems such as accurately controlling engine output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

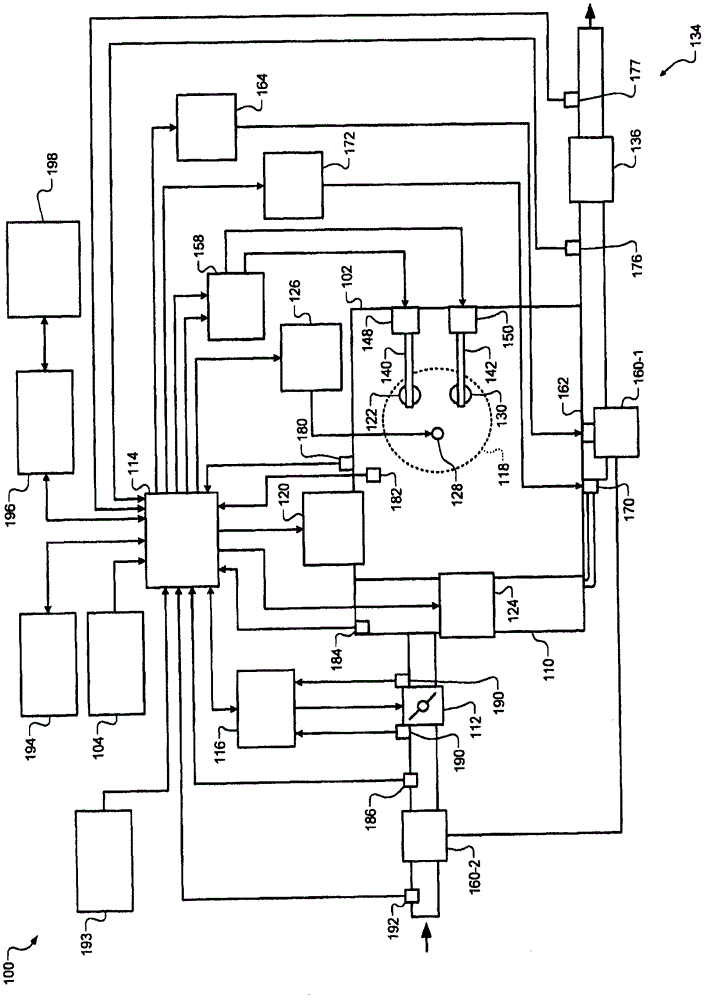

[0065] The engine control module (ECM) controls the torque output of the engine. More specifically, the ECM determines a target value based on the requested amount of torque and controls the engine's actuators based on the target value. For example, the ECM controls intake and exhaust camshaft phasers based on target phaser angles, throttle valve based on target throttle opening area, exhaust gas recirculation (EGR) valve based on target EGR opening, and based on target wastegate The duty cycle controls the wastegate of the turbocharger. The ECM also controls spark timing based on the target spark timing and controls fueling based on the target fueling parameters.

[0066] The ECM may individually use multiple single-input single-output (SISO) controllers, such as proportional-integral-derivative (PID) controllers, to determine the target value. However, when using multiple SISO controllers, target values can be set to maintain system stability at the expense of possible f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com