Heating device for low-speed cookoff of insensitive explosives

A technology for sensitive explosives and heating devices, applied in ammunition, ammunition testing, weapon accessories, etc., can solve the problems of poor stability of heating power, low safety in use, and complicated assembly process, and achieve consistent heating power, high safety, The effect of the simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

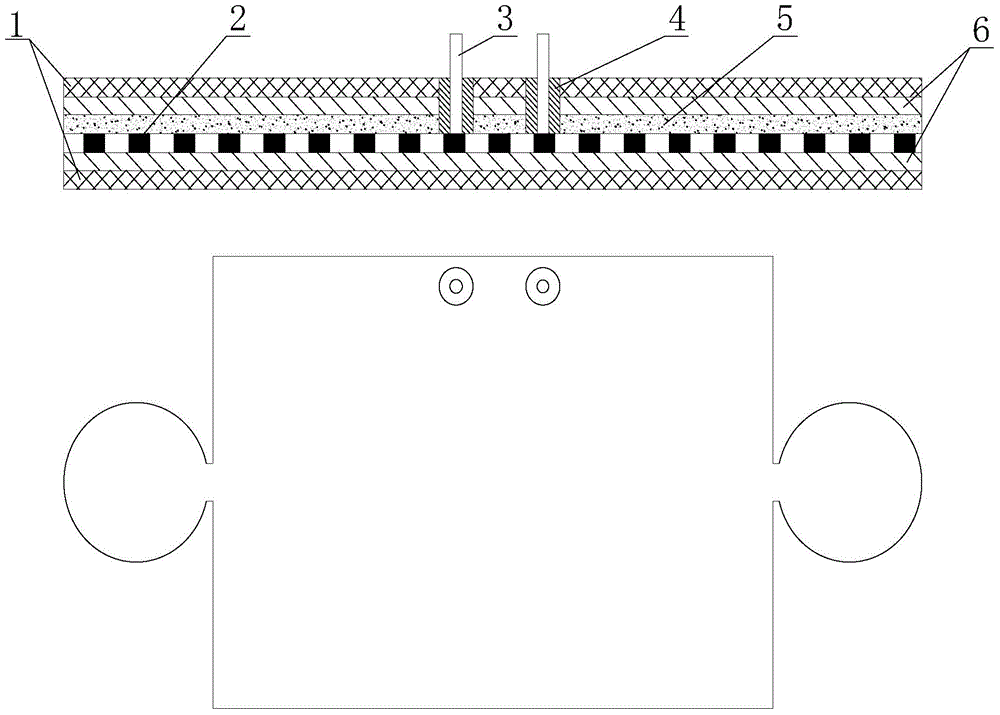

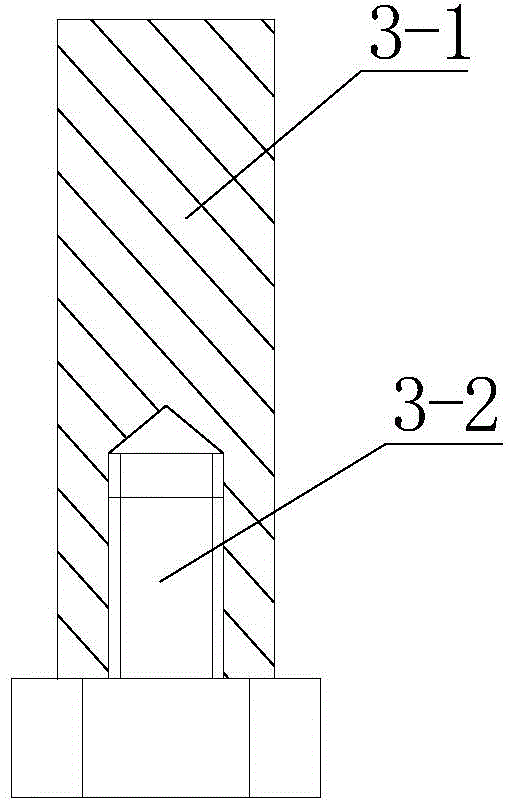

[0021] refer to Figure 1~3 , the present embodiment provides a specific structure and an assembly and manufacturing example of a heating device for slow cook-off of insensitive explosives. , insulating sleeve 4, heat insulating layer 5, insulating layer 6.

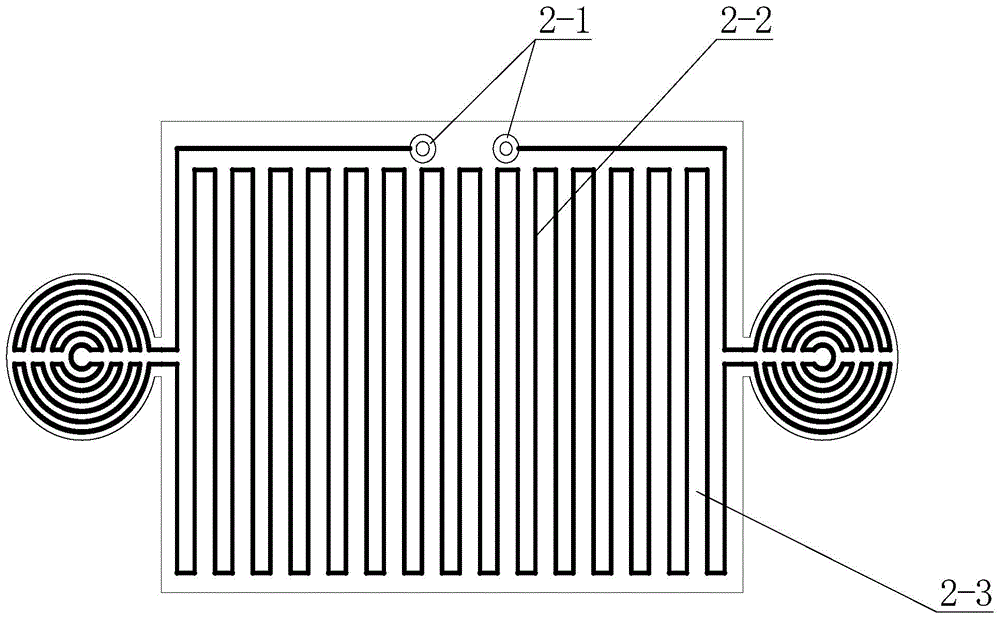

[0022] see figure 2 , Substrate 2-3 is a sheet structure, consisting of a rectangle and two circles, the two circles are respectively connected to the short sides of the rectangle, the short side of the rectangle is 320-470mm, and the long side is 400-600mm. The diameter of the circle is 100-150mm, the thickness of the substrate 2-3 is 5-7mm, and the electric heating sheet 2-2 is a foil metal strip with a thickness of 3-4mm and a width of 6-8mm, which are evenly distributed on the substrate 2-3 according to the serpentine circuit. 3, the distance between adjacent electric heating plates 2-3 is 6-8mm, and the electric ring 2-1 is two flat rings, the inner diameter of the ring is 6-8mm, the outer diameter of the ring is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com