Welding centering checking fixture for automobiles

A technology for automobiles and inspection tools, which is applied in the direction of adopting mechanical devices, measuring devices, mechanical measuring devices, etc. It can solve the problems of too large or too small gaps between matching parts, and achieve the effects of reducing stations, uniform gaps, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

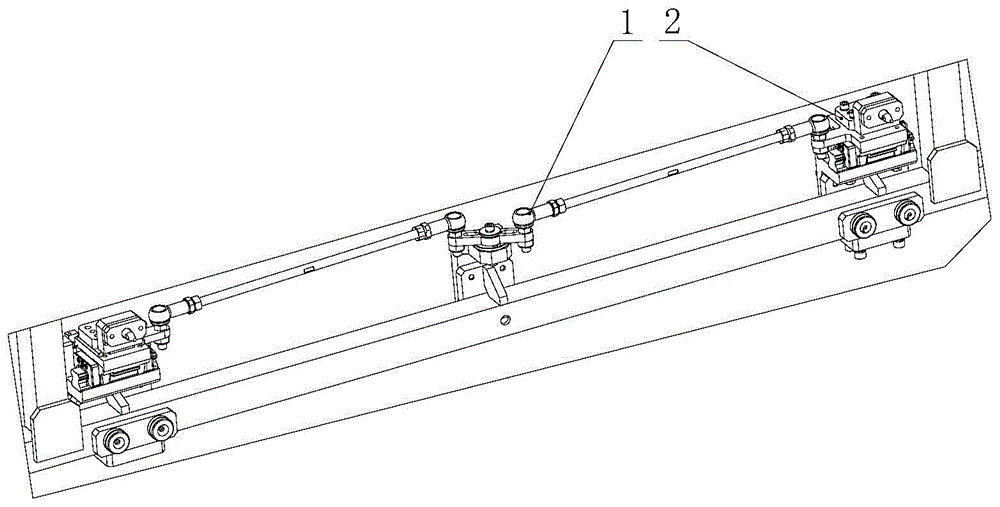

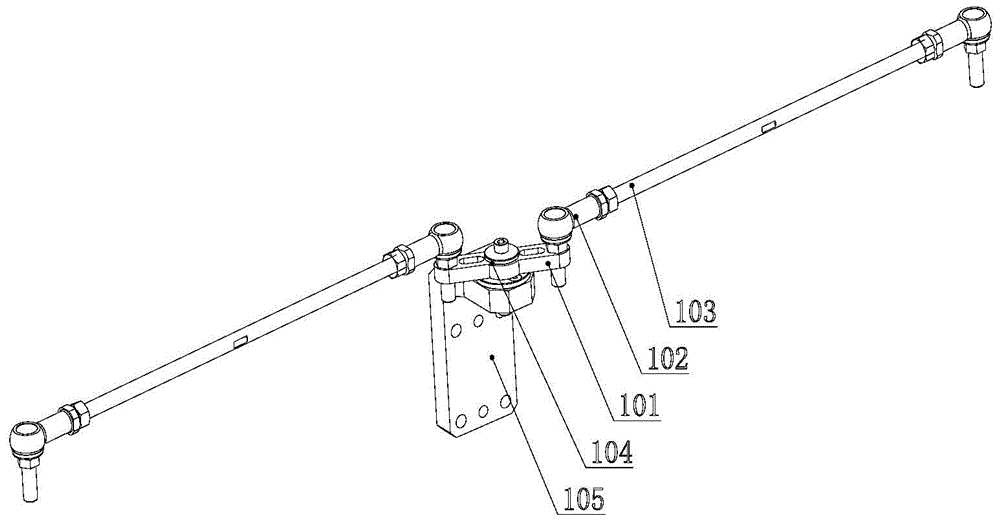

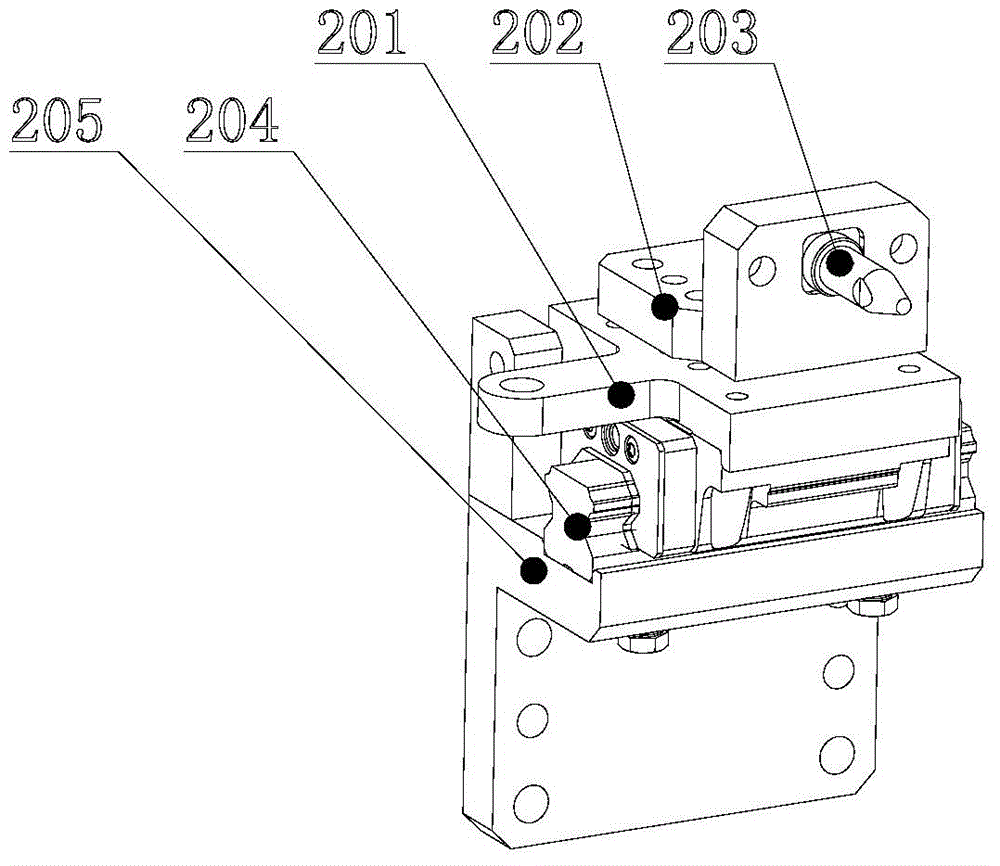

[0009] 1. See figure 1 , figure 2 , image 3 , a kind of automobile welding centering fixture of the present embodiment, it is made up of link mechanism (1), positioning device (2), and wherein positioning device (2) is connected with link mechanism (1) by pin shaft, The positioning pin (201) on the positioning device (2) is positioned on the RPS hole of the vehicle body, and the alignment check of the left and right symmetrical parts of the automobile can be realized through the operation of the linkage mechanism (1).

[0010] 2. See figure 2 , the connecting rod mechanism (1) is made up of turning block (101), joint ball bearing (102), connecting rod (103), revolving pin (104) and repinning seat (105), wherein turning block (101) and joint ball The bearing (102) is connected by a pin shaft, and the joint ball bearing (102) is connected with the connecting rod (103) by threads to adjust the size of the joint ball bearing (102), which can be applicable to different statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com