Testing device and method for bond stress between steel strand and concrete in pre-tensioning-method member

A bonding stress and testing device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem that it is difficult to accurately control the moment when the bond between the steel strand and the concrete fails, and it is difficult to measure the bond between the steel strand and the concrete Stress prestress and other problems, to achieve the effect of accurate and reliable test data, convenient measurement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

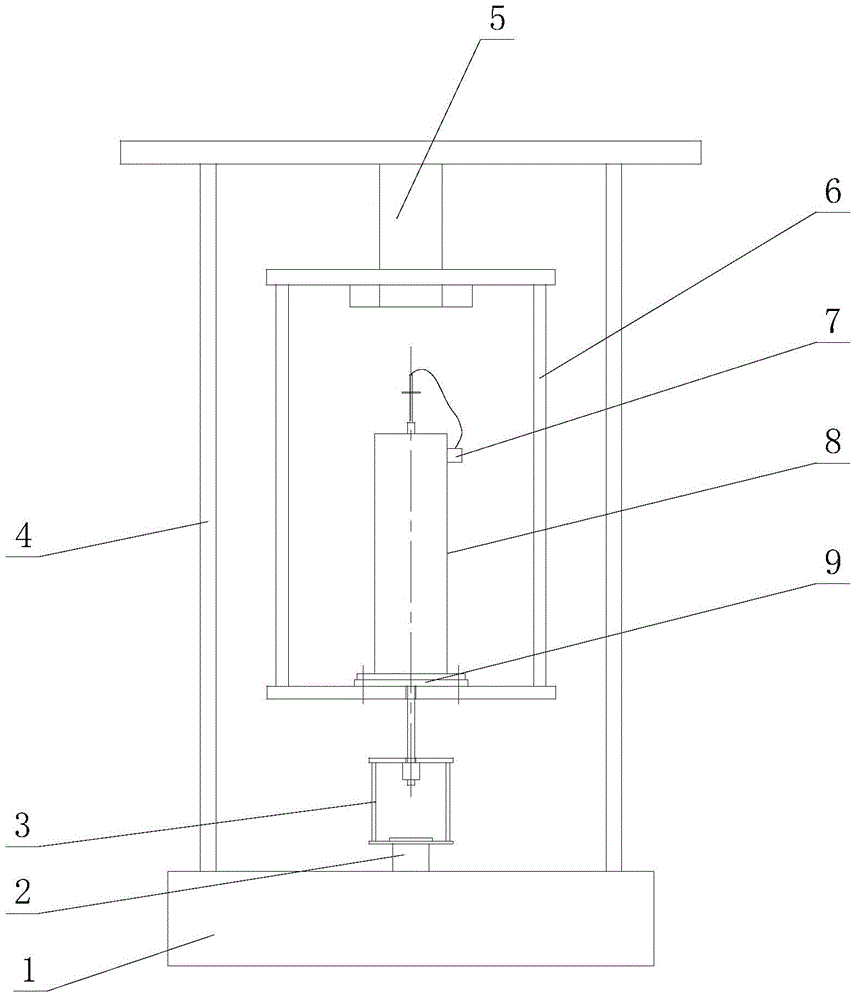

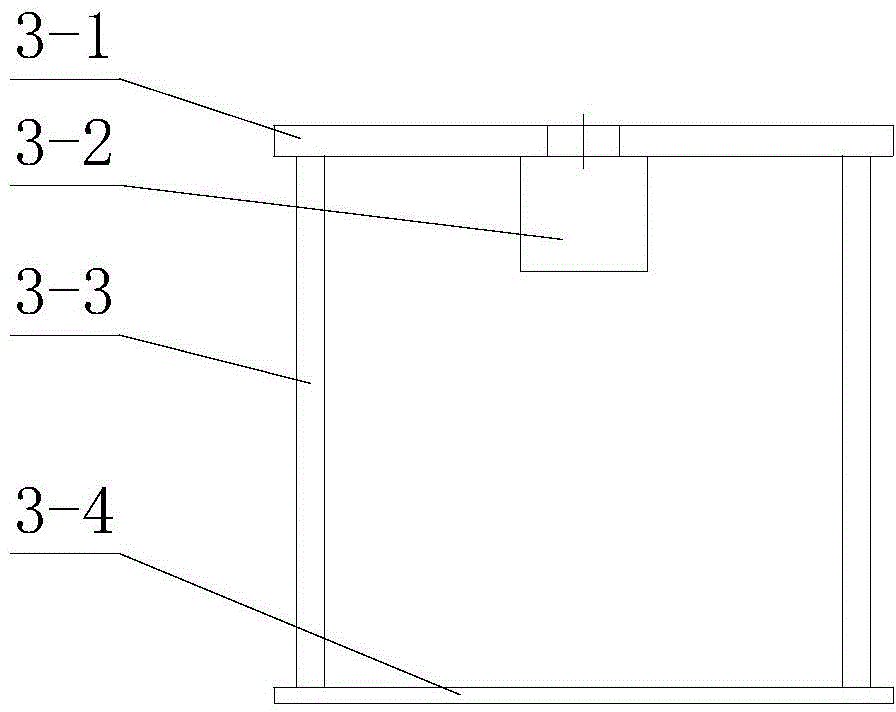

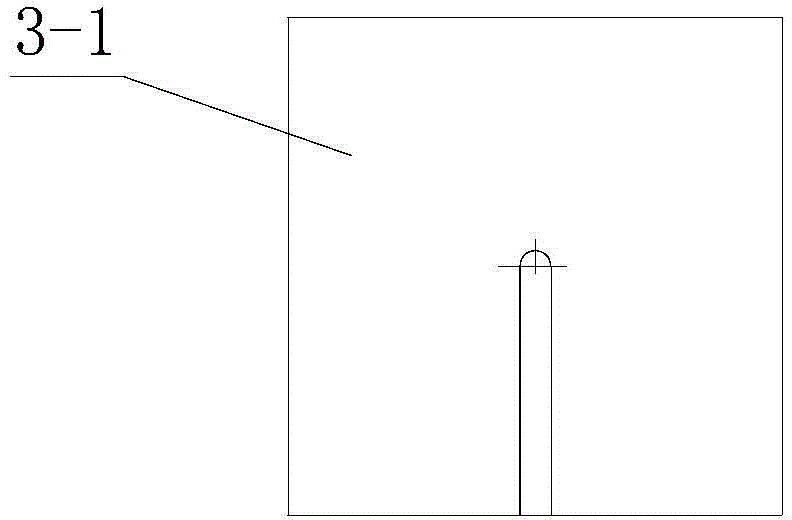

[0021] Depend on figure 1 It can be seen that the bond stress test device between the steel strand and the concrete in the pretensioned member of the present embodiment is composed of a base 1, a hydraulic cylinder 2, a force transmission assembly 3, a support frame 4, a load cell 5, and a sleeve placement frame 6 , sleeve 7, displacement sensor 8 and backing plate 9 are connected to form.

[0022] The base 1 of this embodiment is a cuboid structure, which is used to fix an installation platform of the overall device. A steel strand tensioning mechanism is installed on the base 1. The steel strand tensioning mechanism is mainly capable of placing the pretensioned member to be tested The test platform for fixing the concrete and applying load to the steel strand mainly includes a hydraulic cylinder 2 that can provide the driving force of the load and a support frame 4 that can provide an installation environment for the device that fixes the concrete part of the pretensioned me...

Embodiment 2

[0028] In the test device of the present embodiment, the thickness of the backing plate 9 is 1cm, and the side length is 120mm. There is a steel sleeve 7, the bottom of the sleeve 7 is a square steel plate as large as the backing plate 9, and its four corners pass through the backing plate 9 and the bottom of the sleeve placement frame 6 with threaded fasteners to fasten on the sleeve. On the frame 6, the height h of the sleeve 7 and its diameter d meet: h / d=3 and the diameter d of the sleeve 7 and the maximum particle size d′ of the concrete aggregate in the pretensioned member to be tested The ratio satisfies: d / d′=2.5, that is, the diameter d of the sleeve 7 used in this embodiment is 10 cm, and the height h is 30 cm.

[0029] Other components and their connections are the same as those in Embodiment 1.

[0030] In the method for testing the bonding stress between the steel strand and concrete in the pretensioned member with the test device, step (1) is to fix the steel stra...

Embodiment 3

[0034] In the test device of the present embodiment, the thickness of the backing plate 9 is 2cm, and the side length is 20cm. There is a steel sleeve 7, the bottom of the sleeve 7 is a square steel plate as large as the backing plate 9, and its four corners pass through the backing plate 9 and the bottom of the sleeve placement frame 6 with threaded fasteners to fasten on the sleeve. On the frame 6, the height h of the sleeve 7 and its diameter d meet: h / d=5 and the diameter d of the sleeve 7 and the maximum particle size d′ of the concrete aggregate in the pretensioned member to be tested The ratio satisfies: d / d = 4.5, that is, the diameter d of the sleeve 7 used in this embodiment is 18 cm, and the height h is 90 cm.

[0035] Other components and their connections are the same as those in Embodiment 1.

[0036] The method for testing the bonding stress between the steel strands of the pretensioned member and the concrete using the testing device is also the same as in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com