Maintenance system and method for automatic instrumentation and control equipment

A technology for controlling equipment and maintaining systems, which is applied in the direction of program control and electrical program control in sequence/logic controllers, and can solve the problems that the equipment management system cannot be widely promoted, has not become the mainstream of the industry, and the communication standards are not uniform. Achieve the effect of increasing mean time between failures, reducing equipment professional maintenance personnel, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

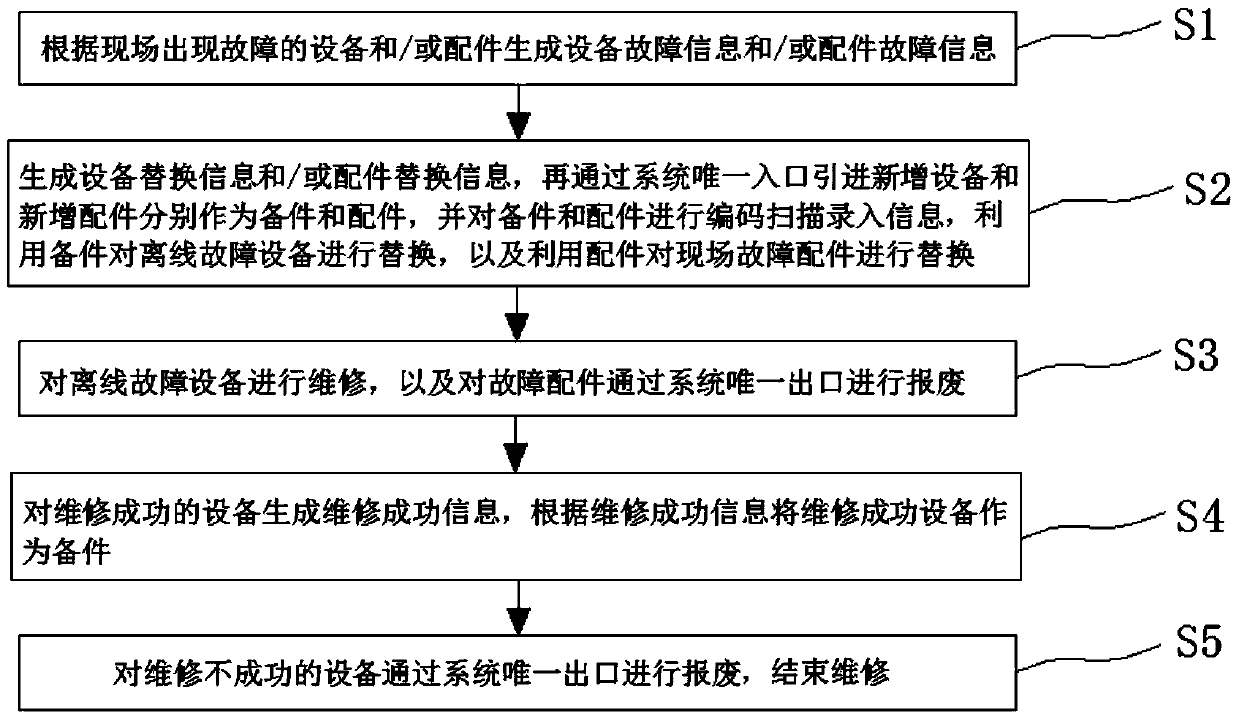

[0043] Such as figure 1 As shown, a maintenance method for automated instruments and control equipment, comprising the following steps:

[0044] Step S1. Generate equipment failure information and / or accessory failure information according to the equipment and / or accessories that have failed on site;

[0045] Step S2. Generate equipment replacement information and / or accessory replacement information according to the equipment failure information and / or accessory failure information, and then introduce new equipment and new accessories as spare parts and accessories respectively through the unique entrance of the system, and perform maintenance on the spare parts and accessories Code scanning and input information,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com